How do you use self-tapping metal screws?

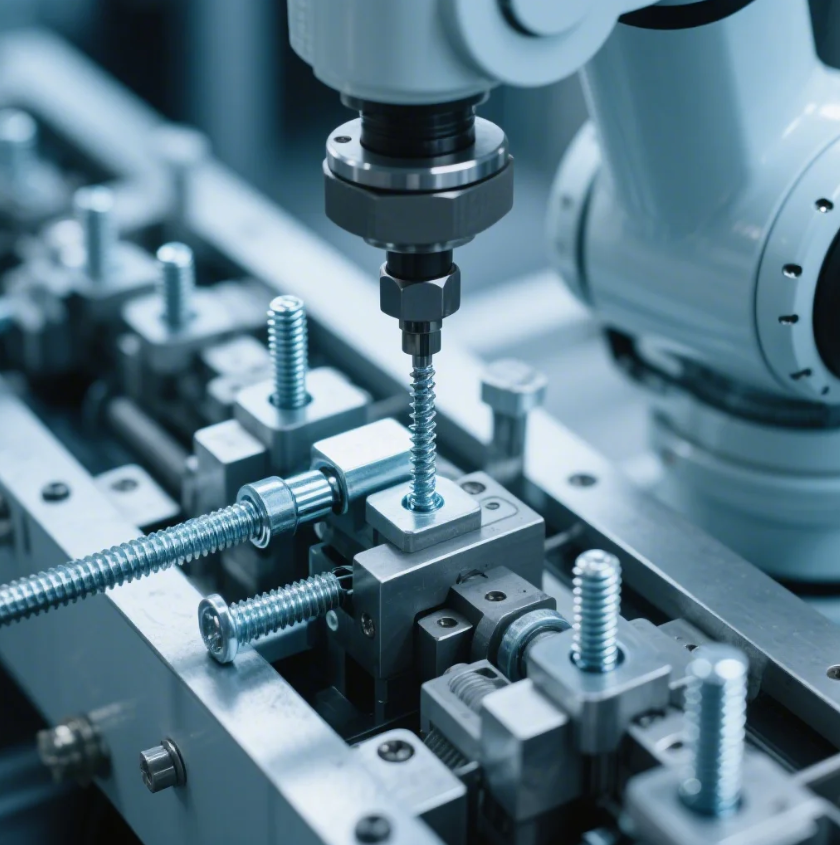

Self-tapping metal screws are an excellent fastener for working with metal, especially when you don’t have access to a drill or pre-drilled holes. They are designed to tap their own threads as they are driven into the material, making them a popular choice for projects that involve metal or thin sheet materials.

Snippet paragraph: Using self-tapping screws for metal requires understanding how they work, the materials they’re suitable for, and the best techniques for installation. Let’s explore how to use them properly.

In this article, we’ll cover how to use self-tapping screws in metal, whether you need to pre-drill, and the best techniques to achieve a strong and secure hold.

Do I need to pre-drill self-tapping metal screws?

One of the advantages of self-tapping screws is that they do not typically require pre-drilling, as they are designed to create their own threads as they are driven into the material. However, in certain situations, it may still be beneficial to create a pilot hole to guide the screw or to reduce the force needed for insertion.

Snippet paragraph: Self-tapping screws can often be used without pre-drilling, but a pilot hole may help guide the screw and make installation easier.

When to Pre-Drill:

- Hard Metals: If you’re working with harder metals, it can be helpful to drill a small pilot hole first to make the process smoother and reduce the risk of stripping the screw.

- Large Screws: For larger self-tapping screws, a pilot hole ensures that the screw has enough space to tap threads without excessive force.

- Precision: Pre-drilling a small hole can improve accuracy and help guide the screw into place, especially in high-precision projects.

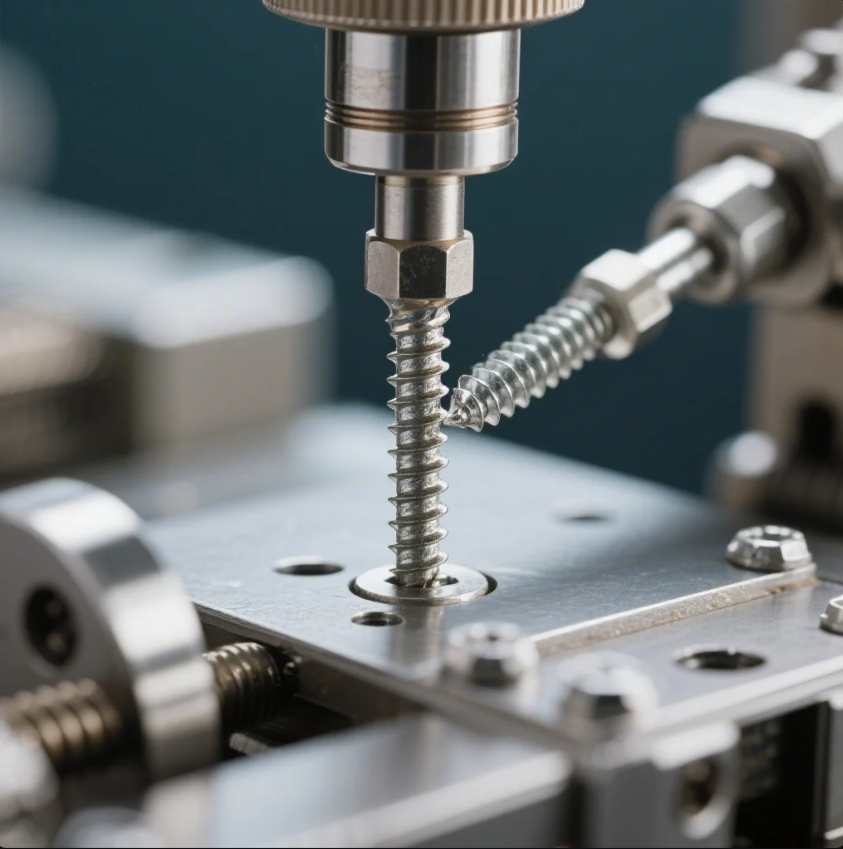

How to Pre-Drill:

- Choose the Right Drill Bit Size: The pilot hole should be slightly smaller than the diameter of the self-tapping screw. Check the screw manufacturer’s recommendations for the best drill bit size.

- Drill the Hole: Use a drill to make a clean pilot hole, ensuring that it’s straight and aligned with the area where you want to place the screw.

- Drive the Screw: After drilling the pilot hole, drive the self-tapping screw into the hole using a screwdriver or drill driver.

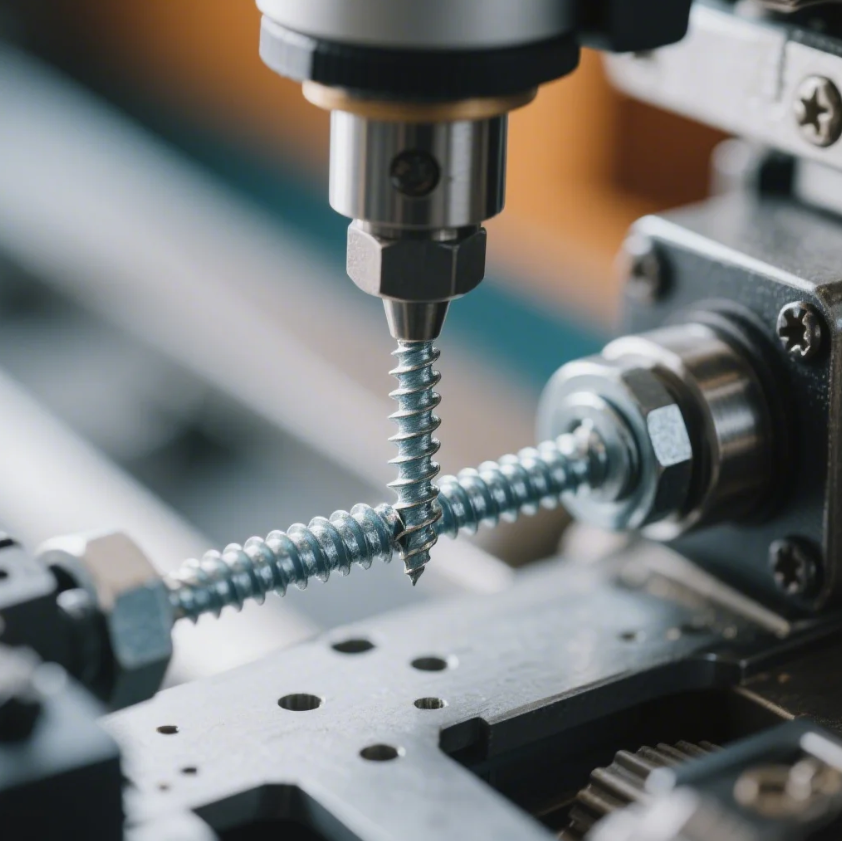

Can self-tapping screws drill through metal?

Yes, self-tapping screws are specifically designed to drill through metal and create their own threads as they are driven in. These screws have a sharp point that allows them to cut through metal, making them ideal for applications where you need to fasten materials without pre-drilling.

Snippet paragraph: Self-tapping screws are designed to drill into metal by cutting their own threads, making them effective for securing materials without needing a pre-drilled hole.

How Self-Tapping Screws Work:

- Pointed Tip: The tip of a self-tapping screw is sharp and designed to pierce the surface of the metal as it’s turned.

- Cutting Threads: As the screw is driven into the material, the threads on the screw cut through the metal and create a secure hold.

- Materials: Self-tapping screws work best on thin to medium metals, such as sheet metal, aluminum, or soft steel.

Advantages:

- No Pre-Drilling: The main advantage is that you don’t need to pre-drill a hole, saving time and effort.

- Variety: Self-tapping screws are available in various lengths and diameters, making them versatile for different applications.

How to make a hole for a screw in metal?

If you are working with thicker metal or a material that’s harder to penetrate, you may need to create a hole for the self-tapping screw to sit in. Here’s how to make a hole for a screw in metal effectively:

Snippet paragraph: Making a hole for a screw in metal involves using the right tools, such as a drill, and selecting the correct screw size for a secure fit.

Steps for Making a Hole for a Self-Tapping Screw:

- Select the Right Drill Bit: Choose a drill bit that is slightly smaller than the diameter of the self-tapping screw to create a guide hole.

- Mark the Spot: Use a pencil or marker to accurately mark where you want the hole to be drilled.

- Drill the Hole: Use a drill to carefully make a hole at the marked spot. Be sure to use the correct drill speed to avoid overheating the metal and damaging the drill bit.

- Insert the Screw: Once the hole is made, insert the self-tapping screw and use a screwdriver or drill to tighten it into place.

Tips:

- Lubrication: Use a small amount of lubricant (such as oil) on the screw or hole to make the process smoother and reduce friction.

- Cooling: If you’re drilling through thick metal, periodically stop to let the metal and drill cool down to avoid overheating.

How thick of metal can self-tapping screws go through?

Self-tapping screws are effective for many metal types, but their ability to penetrate depends on the thickness and hardness of the metal. They are generally suitable for thin to medium gauge metals, but thicker materials may require specialized fasteners or pre-drilling.

Snippet paragraph: Self-tapping screws work best for thin to medium gauge metal. Thicker metal may require additional preparation or a different fastener.

Metal Thickness for Self-Tapping Screws:

- Thin Metal (Up to 1/8" thick): Self-tapping screws can easily go through metals like aluminum, steel, and sheet metal up to 1/8" thick without needing a pre-drilled hole.

- Medium Gauge Metal (1/8" to 1/4" thick): For medium thickness metal, self-tapping screws can work, but a pilot hole may be necessary for smoother insertion.

- Thicker Metal (Over 1/4" thick): Self-tapping screws may struggle with thicker metal. For these materials, it’s often better to use larger, more specialized fasteners or drill a pilot hole to reduce strain on the screw.

Recommendations:

- Sheet Metal: Ideal for self-tapping screws, as they are commonly used in HVAC, automotive, and general construction applications.

- Aluminum and Copper: These softer metals are also suitable for self-tapping screws.

- Steel and Stainless Steel: These stronger metals can be drilled with self-tapping screws, but harder grades of steel may require pre-drilling or high-strength screws.

Conclusion

Self-tapping screws are a convenient and efficient fastener for working with metal, as they can drill and tap their own threads without the need for a drill. By choosing the right screw and technique, you can easily secure metal materials without pre-drilling. Whether you’re working with thin sheet metal or need to fasten thicker metals, self-tapping screws can provide a strong, secure connection with minimal effort.

Always remember to select the appropriate screw size for your project, and if you’re working with harder metals, consider using a pilot hole or lubricant for smoother installation. With the right approach, self-tapping screws are an excellent choice for metal fastenings.