How to Choose a High-Quality Metal Stamping Parts Supplier?

Finding reliable metal stamping suppliers can be frustrating and costly. Many manufacturers struggle with quality issues, missed deadlines, and communication problems that impact their production schedules and bottom line.

When selecting a metal stamping parts supplier, you should evaluate their certification standards, production capabilities, quality control processes, and customer service. The right supplier will have ISO certification, advanced equipment, strict quality protocols, and responsive communication channels.

Ready to solve your metal stamping sourcing challenges? Let\’s explore the essential factors that will help you identify trustworthy suppliers who can deliver consistent quality and meet your specific requirements.

What Key Criteria Should You Use to Evaluate Metal Stamping Parts Suppliers?

Finding the right metal stamping supplier can be overwhelming. Many purchasing managers waste valuable time and resources dealing with suppliers who promise quality but deliver substandard parts that require rework or replacement. The most important evaluation criteria for metal stamping suppliers include quality certifications, manufacturing capabilities, industry experience, quality control processes, and communication efficiency. ISO-certified suppliers with at least 10 years of experience typically provide more reliable service and consistent product quality.

Understanding Quality Certification Standards

Quality certifications serve as the foundation for reliable manufacturing operations. These standards ensure that suppliers follow consistent processes that meet international requirements. #### Common Certifications to Look For

| — | ||||||

|---|---|---|---|---|---|---|

| ISO 9001 | Quality management system | Ensures consistent quality and continuous improvement | ||||

| ISO 14001 | Environmental management | Demonstrates environmental responsibility | ||||

| IATF 16949 | Automotive quality standard | Critical for automotive industry suppliers | ||||

| ISO 45001 | Occupational health and safety | Shows commitment to worker safety |

When evaluating potential suppliers, I always recommend prioritizing those with ISO 9001 certification at minimum. This certification verifies that the company follows standardized quality management processes. During my visits to manufacturing facilities across Asia, I\’ve consistently found that ISO-certified suppliers like Shandong Prime International Trade Co., Ltd. maintain better documentation, have clearer processes, and produce more consistent results. ### Assessing Manufacturing Capabilities

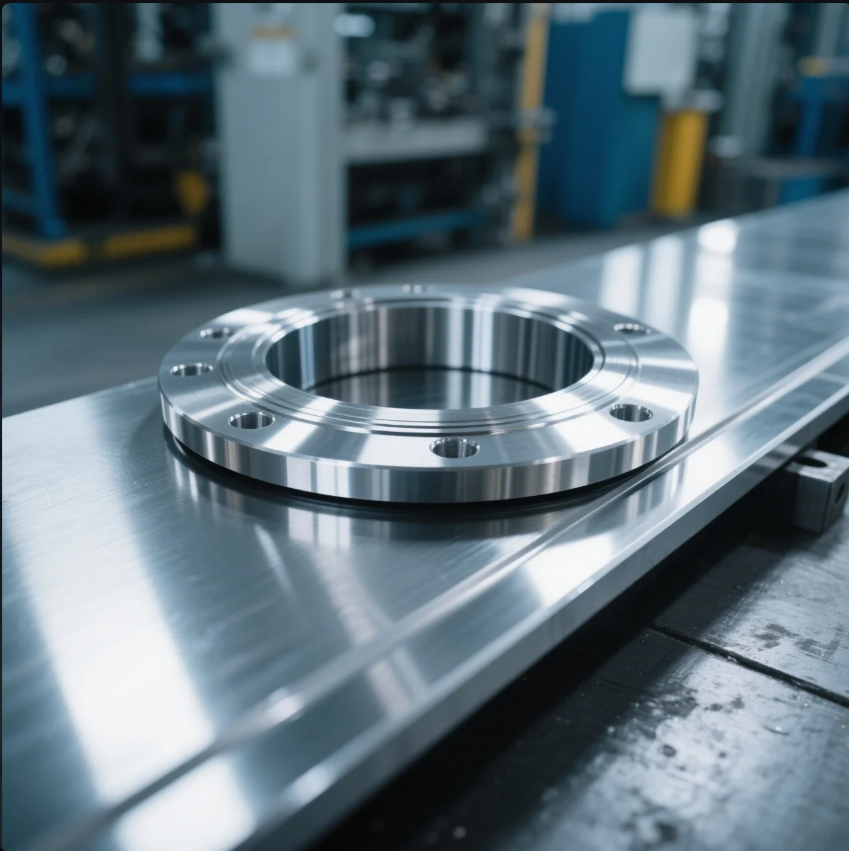

The right supplier must have appropriate equipment and technical expertise to meet your specific requirements. This includes having the right stamping presses, tooling capabilities, and secondary processing options. #### Key Manufacturing Capabilities to Evaluate

- Press capacity (tonnage and bed size)

- Material types they can process

- Tolerance capabilities

- Secondary operations (welding, assembly, etc.)

- Design assistance and tooling development

I recently worked with a client who switched to a supplier with ten production lines after experiencing constant delays with their previous vendor who had limited capacity. The new supplier could handle volume fluctuations much more efficiently, reducing lead times by 40%. ## How Can You Ensure the Quality and Precision of Stamping Parts?

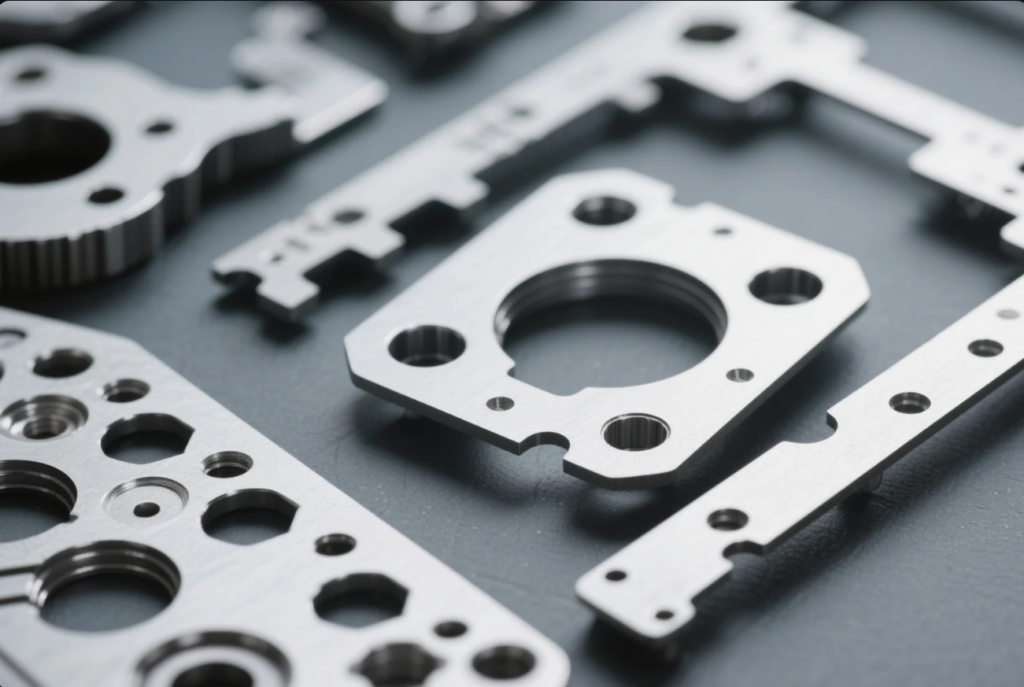

Quality issues with metal stamping parts can lead to assembly problems, product failures, and costly recalls. Many manufacturers struggle to find suppliers who maintain consistent quality across production runs. To ensure stamping part quality, implement regular supplier audits, request material certifications, establish clear quality specifications, require statistical process control, and arrange third-party inspections when necessary. Working with suppliers who have in-house testing facilities can significantly reduce quality risks.

Implementing Effective Quality Control Measures

Quality control should be proactive rather than reactive. The best suppliers integrate quality checks throughout their production process rather than relying solely on final inspections. #### Essential Quality Control Elements

- Material Verification: Suppliers should provide material certifications and conduct incoming material inspections.

- First Article Inspection: Detailed inspection of the first production pieces before full production begins.

- In-Process Checks: Regular measurements and inspections during production.

- Statistical Process Control (SPC): Using statistical methods to monitor and control production processes.

- Final Inspection: Comprehensive checks before shipping.

During my visit to Prime\’s manufacturing facility, I was impressed by their implementation of automated optical inspection systems that could detect defects human inspectors might miss. This technology has helped them maintain a remarkably low defect rate of less than 0.5% across their stamping operations. ### Setting Clear Quality Specifications

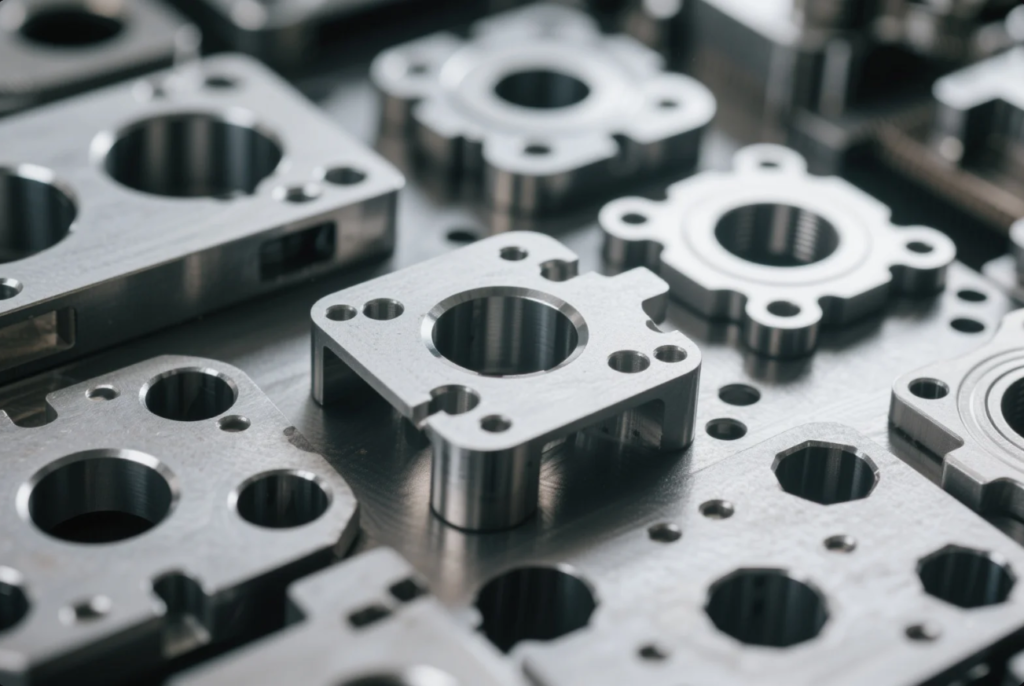

Clear communication about quality requirements is essential for successful partnerships with stamping suppliers. Misunderstandings about specifications often lead to quality issues. #### Creating Effective Quality Specifications

| — | ||||||

|---|---|---|---|---|---|---|

| Dimensional tolerances | Acceptable variation in measurements | ±0.05mm for critical dimensions | ||||

| Material requirements | Type, grade, thickness, finish | SPCC steel, 1.2mm thickness | ||||

| Surface finish | Appearance and roughness requirements | Ra 1.6 μm, no visible scratches | ||||

| Special characteristics | Critical features requiring extra attention | Flatness of mounting surfaces | ||||

| Packaging requirements | How parts should be protected | Individual plastic bags, foam dividers |

I\’ve found that suppliers with extensive experience in global exports, like those with 20+ years in the industry, are typically better at interpreting and meeting international quality standards and specifications. ## What Are the Best Practices for Global Sourcing of Metal Stamping Parts?

Global sourcing presents unique challenges including communication barriers, logistics complexities, and quality verification from a distance. These obstacles can lead to project delays and unexpected costs. Best practices for global metal stamping sourcing include conducting thorough supplier qualification, establishing clear communication protocols, implementing quality agreements, planning for longer lead times, and developing contingency plans. Working with suppliers who have experience serving your target market can significantly reduce complications.

Navigating International Supply Chain Challenges

International sourcing requires careful planning and risk management. Understanding potential challenges helps you develop effective strategies to overcome them. #### Common Global Sourcing Challenges and Solutions

| — | ||||||

|---|---|---|---|---|---|---|

| Communication barriers | Misunderstandings and delays | Regular video conferences, detailed documentation | ||||

| Time zone differences | Delayed responses | Scheduled communication windows, local representatives | ||||

| Shipping delays | Production disruptions | Buffer inventory, multiple shipping options | ||||

| Quality verification | Inconsistent product quality | Third-party inspections, supplier quality agreements | ||||

| Cultural differences | Misaligned expectations | Cultural training, clear written agreements |

In my experience working with global suppliers, those with dedicated export departments and English-speaking staff make the process much smoother. Prime\’s international trade experience since 1993 has given them valuable insights into the needs of global customers, particularly in North America and Europe. ### Optimizing Logistics and Packaging

Proper packaging and logistics planning are crucial for international shipments of metal stamping parts. Inadequate protection can result in damaged goods and production delays. #### Effective Packaging and Shipping Strategies

- Corrosion Protection: Using VCI paper or oil coating for rust prevention

- Custom Packaging: Designing packaging specific to part geometry

- Container Optimization: Maximizing space utilization while ensuring part protection

- Documentation: Proper labeling and paperwork for customs clearance

- Shipping Method Selection: Choosing between air, sea, or combined transport based on urgency and cost

During a recent project, we reduced shipping damage by 95% by working with a supplier who implemented custom-designed packaging with dividers and anti-corrosion measures. This attention to packaging details is particularly important for precision components that can be damaged during long-distance transportation. ### Building Long-Term Supplier Relationships

Transactional approaches to supplier management often lead to inconsistent results. Developing strategic partnerships yields better outcomes for both parties. #### Benefits of Strategic Supplier Relationships

- Priority Treatment: Preferred customers often receive priority during busy periods

- Continuous Improvement: Long-term partners are more invested in process improvements

- Cost Optimization: Established relationships often lead to better pricing and terms

- Knowledge Transfer: Suppliers become familiar with your specific requirements

- Collaborative Problem-Solving: Partners are more willing to help resolve issues quickly

I\’ve witnessed how companies that treat suppliers as strategic partners rather than interchangeable vendors typically receive better service, more flexible terms, and higher priority during material shortages or capacity constraints. ## Conclusion

Selecting the right metal stamping parts supplier is crucial for ensuring product quality, controlling costs, and maintaining production schedules. By evaluating certification standards, manufacturing capabilities, quality control processes, and communication efficiency, you can identify reliable partners for your metal component needs. For businesses seeking high-quality metal stamping parts with consistent quality and reliable delivery, I recommend contacting Shandong Prime International Trade Co., Ltd. With over 20 years of experience in providing one-stop processing services for metal components, ISO certification, and ten production lines, Prime offers the expertise and capacity to meet diverse industrial requirements. Contact Prime today for a free consultation, quotation, and customized solution for your metal stamping needs. Their quick delivery times and stable quality have made them a trusted partner for companies worldwide. Visit https://primecustomparts.com/ or email [email protected] to discuss your specific requirements and experience the difference of working with a truly professional metal parts supplier.

2 Responses

Thank you for your valuable feedback! At Prime, we understand that unstable quality and delayed shipments can greatly impact your business. That’s why we are committed to strict ISO-certified quality management, rapid production, and secure export packaging. If you have any questions or need assistance with sourcing custom CNC or stamping parts, feel free to contact us directly. We’re always here to help you find the best solutions for your projects!