How to Choose the Right Metal Casting Parts? A Complete Guide from Custom Prototypes to Mass Production

Metal casting parts1 selection troubles many OEM buyers. Confusion around process, quality, and supplier choices2 often leads to delays and waste.

Choosing the right custom metal casting parts1 involves understanding processes, supplier certifications, and project requirements. Each casting method fits different needs for cost, geometry, and material. Selecting a certified, experienced casting parts manufacturer2 ensures quality, reliability, and project success.

Every OEM buyer1 wants to reduce risk, cut costs, and secure reliable supply. In this guide, I will walk you through every key decision, from prototype to mass production2, to help you win in the market.

Why Are Custom Casting Parts Growing in Popularity Among OEM Buyers?

OEM buyers1 need parts that fit their designs perfectly. Off-the-shelf components often fail to meet unique requirements, forcing costly adaptation.

Custom casting parts solve complex geometry, reduce weight, cut costs, and boost durability. Aluminum die casting1, ductile iron casting, and stainless steel casting deliver excellent performance in automotive, machinery, and electronics. Choosing the right casting parts manufacturer2 enables high-precision, reliable components tailored to each application.

Deeper Dive: The OEM Drive Toward Custom Metal Casting Solutions

Today, more engineers request customized casting solutions1 for new projects. Here are key reasons why custom casting parts2 matter more than ever:

What Do Custom Metal Casting Parts Solve?

- Complex Geometry: Custom casting1 makes intricate shapes that CNC or welding cannot achieve cost-effectively.

- Weight Reduction: Engineers replace steel with lightweight aluminum castings2 to save weight and energy.

- Cost Efficiency: Casting complex assemblies as one part reduces machining and welding steps.

- Performance: Custom alloys and precise tolerances improve wear resistance and extend service life.

Where Are Custom Casting Parts Used?

| Industry | Typical Casting Solution | Benefit |

|---|---|---|

| Automotive | Aluminum die casting1, ductile iron | Weight savings, fuel efficiency |

| Industrial Machinery | Ductile iron casting2, steel casting | Durability, shock resistance |

| Electronics | Aluminum die casting1, stainless steel | Thermal conductivity, shielding |

| Energy | Stainless steel, aluminum | Corrosion, temperature resistance |

Why Does Manufacturer Choice Matter?

Not every supplier can make reliable, repeatable custom parts. Prime, for example, brings over 20 years of experience, ISO 9001 certification1, and advanced project support. I have seen clients reduce scrap2, avoid costly rework, and launch products faster by working with our integrated team.

Choosing a partner who understands OEM engineering needs1, manages tooling well, and offers strong quality systems brings real value. If you want to innovate in your market, custom casting parts2 are essential.

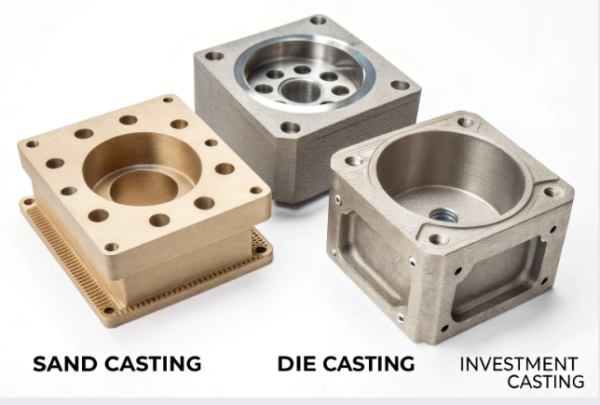

Which Key Metal Casting Process Is Best: Sand Casting, Die Casting, or Investment Casting?

Choosing the wrong casting process1 can ruin a project. Each method has clear strengths and trade-offs, so you need to match your project goals2 to the process.

Deeper Dive: Comparing Metal Casting Methods—What Should Buyers Really Know?

Selecting a casting process1 is not just about price. Let’s review how the three main casting services2 stack up:

Sand Casting

- Best for: Large, simple parts; prototypes; lower cost.

- Pros: Low mold cost1, flexible for size/material, short lead times2.

- Cons: Rougher surface, limited dimensional accuracy.

Aluminum Die Casting

- Best for: High-volume, thin-walled, complex shapes.

- Pros: High precision1, smooth finish, rapid cycle times2.

- Cons: High mold investment, limited to non-ferrous metals.

Investment Casting (Lost Wax Casting)

- Best for: Small, intricate parts, fine features.

- Pros: Excellent accuracy1, supports many alloys, complex details2.

- Cons: Costly tooling, longer cycles, not for very large parts.

| Process | Setup Cost | Tolerance Range | Surface Finish | Part Volume | Compatible Metals |

|---|---|---|---|---|---|

| Sand Casting | Low | ±0.5-2mm | Coarse | Low-Medium | Most alloys |

| Die Casting1 | High | ±0.1-0.3mm | Smooth | High | Aluminum, Zinc, Magnesium |

| Investment Casting2 | Medium | ±0.1-0.5mm | Very smooth | Low-Medium | Steel, Stainless, Brass |

Practical Tips for Choosing Your Casting Process

- For high-precision and repeatable quality, choose die casting1.

- For large or heavy parts, sand casting saves cost.

- For complex, detailed parts, investment casting2 excels.

- Consider total cost, not just mold price—think about secondary machining and finishing.

- Ask for sample parts and CMM inspection reports to validate supplier capability.

Mistakes happen when buyers ignore these differences. I have seen projects fail1 when the wrong process2 was used for the intended application.

How to Evaluate a Reliable Metal Casting Supplier? Key Quality and Technical Standards

Many buyers worry about quality issues, late deliveries, and poor after-sales service. These problems often start with poor supplier selection1 and weak technical vetting2.

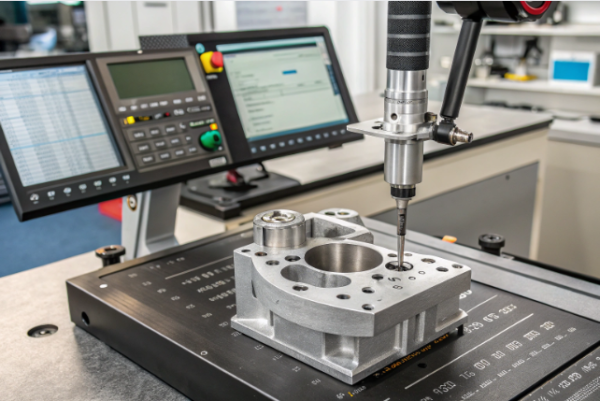

Look for a metal casting parts manufacturer with ISO 90011, strong CMM inspection2, and robust quality control. Suppliers should support DFM, provide inspection reports, and use methods like X-ray, spectrometer, and leak tests. Always ask about tolerance capability, traceability, and defect handling before placing an order.

Deeper Dive: What Separates a Quality Casting Manufacturer from the Rest?

I have worked with hundreds of buyers across North America, Europe, and Australia. They always care about the same issues: quality control1, certification2, and communication. Here is what you must look for:

Supplier Certifications and Capabilities

- ISO 9001: Ensures standardized, documented quality systems.

- Internal CMM Inspection: Measures dimensions with high precision, catches defects early.

- DFM Support: Helps you optimize your design for casting, reducing risk and waste.

- Material Traceability1: Ensures every part can be traced back to its batch and process.

- Comprehensive Testing2: X-ray, spectrometer, and leak testing catch invisible flaws.

Typical Quality Inspection Workflow

| Step | Description |

|---|---|

| DFM Review | Engineering checks for manufacturability1 |

| Mold Inspection | Dimensional checks before casting starts |

| First Article | CMM and visual inspection of first-off parts |

| Process Control | In-process checks during production |

| Final Inspection2 | Visual, mechanical, and NDT (X-ray) tests |

| Packaging Check | Verifies packaging meets requirements |

Questions to Ask Your Casting Supplier

- What tolerances can you hold for this process and alloy?

- Do you provide material certificates1 and full traceability?

- How do you handle non-conformances like porosity or dimension issues?

- What is your experience with export packaging and shipping?

- Can I get a detailed inspection report2 before shipping?

Red flags include vague answers, missing documentation, and no ISO certification1. Choose suppliers who provide clear, written guarantees and strong technical support2. In my experience, these steps avoid 90% of future headaches.

How to Accelerate Your Casting Project from Prototype to Mass Production?

Getting from idea to final product can be slow and costly. Delays in quoting, design, and validation waste valuable time and budget.

A streamlined process1 includes fast quoting, expert DFM review, in-house mold making, and rapid sampling2. With the right casting parts manufacturer, buyers get quick feedback, validated prototypes, and efficient ramp-up to large orders. Advanced tooling and project management minimize risk and cut lead times.

Deeper Dive: A Real Project Walkthrough and Keys to Faster, Better Cast Parts

Let me share a real story from Prime’s project book. An EU machinery client wanted to replace welded steel brackets with aluminum gravity castings1. They aimed to reduce weight, improve corrosion resistance2, and cut costs. Here is how we delivered:

Step-by-Step: From Quoting to Mass Production

- Rapid Quotation: The client sent 3D files and requirements. We responded with a detailed quote in 24 hours.

- DFM Review: Our engineering team suggested minor geometry tweaks for casting feasibility.

- Mold Tooling1: We built precision steel molds using advanced CNC machining. Tooling was complete in 3 weeks.

- Sampling: First-off samples were ready for review in 10 days. We supplied CMM and X-ray inspection reports.

- Validation: Customer approved the parts after functional testing and fit checks.

- Mass Production2: We scaled up to 2,000 parts per month, delivering on time with strict packaging controls.

Results Table: Aluminum Gravity Casting vs. Welded Steel

| Metric | Welded Steel Bracket | Aluminum Gravity Casting | Improvement |

|---|---|---|---|

| Weight (kg/part) | 5.5 | 3.5 | 36% reduction |

| Cost (EUR/part) | 22 | 13 | 40% reduction |

| Corrosion Resistance1 | Moderate | High | Significant increase |

| Production Time2 | 10 days/batch | 7 days/batch | 30% faster |

Project Management Tips for Success

- Always insist on DFM and prototype validation1 before committing to full tooling.

- Ask for regular project updates and sample inspection photos.

- Define packaging, labeling, and shipping details early to avoid surprises.

- Choose a supplier with in-house tooling and strong logistics support2.

Why Advanced Tooling and Quick Prototyping Matter

Prime’s in-house tooling and rapid prototyping reduced our customer’s time to market1 by over 30%. Fast feedback loops, real-time engineering support2, and robust quality controls delivered stable, repeatable results. When you want to win in your market, speed and reliability matter just as much as cost.

Conclusion

Choosing the right custom metal casting parts1 and supplier unlocks performance, saves cost, and ensures reliable supply.

I encourage you to contact Prime today for a free expert consultation, detailed quotation, and fast project proposal. Our certified team guarantees quick delivery, stable quality, and one-stop OEM casting solutions2. Get in touch now and let’s build your next success.

Contact Us

📧 Email us: [email protected]

🌐 Visit: https://primecustomparts.com

Get a free quote, custom tool configuration, and fast delivery worldwide. Every order comes with setup support.

-

Explore this link to understand how custom metal casting parts can enhance performance and reduce costs. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Discover the advantages of one-stop OEM casting solutions for streamlined production and reliable supply.

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩