Below is the enhanced full English version of the article with **40+ # How to Choose the Right Plastic Material for Custom Parts?

Having repeated product failures or post-sale returns? The root cause may be poor material selection.

Choosing the right plastic ensures parts perform well under stress, heat, and impact. You must align plastic properties with your application needs. This guide simplifies the process.

Most failed plastic parts weren’t designed with the material in mind. I’ve seen it cost companies thousands in recalls. Here’s how to prevent that.

How to choose the right plastic material?

Plastic failure costs more than money—it erodes trust and market share.

Smart plastic selection starts with understanding how the part is used: stress, heat, environment, and regulation shape your options.

Dive Deeper: Match properties to function

Let’s walk through how we do this at Prime when a client sends us a drawing.

Step 1: Define the Environment

| Use Case | Preferred Material | Reason |

|---|---|---|

| Constant Heat (120–150 °C) | PPS, PEEK, PSU | Maintains strength at temp[^1] |

| Outdoor UV + rain | ASA, PC‑ABS | UV stable, impact resistant[^2] |

| Light load + low cost | HDPE, PP | Low‑cost, easy to mold[^3] |

| Low friction, sliding | Acetal (POM), UHMW | Wear resistance[^4] |

| Food or medical contact | FDA‑grade PP, HDPE | Food‑safe certification[^5] |

UL Prospector offers material performance data; Matmatch and MakeItFrom help compare polymers.

Step 2: Compare Mechanical Strength

- High stress loads: Nylon 66, Glass‑filled Nylon

- Snap fits: PP or Nylon

- Vibration damping: TPU, TPE

Use Omnexus for material specifications, and crosscheck with MakeItFrom.com data.

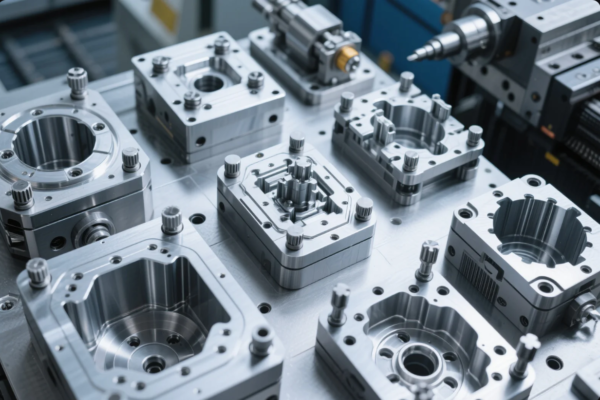

Step 3: Match Processing Needs

| Process Type | Recommended Plastics | Why |

|---|---|---|

| CNC Machining | ABS, POM, Acrylic, Nylon | Dimensional stability[^6] |

| Injection Molding | PP, PC, PA66, TPU | Mold flowability[^7] |

| 3D Printing | PLA, PETG, ABS | FDM compatibility[^8] |

Step 4: Compliance & Cost

- Low‑cost: HDPE, PP (\~\$1/kg)

- Mid‑range: ABS, PC (\~\$2–3/kg)

- Premium: PEEK, PVDF (\~\$8–20/kg)

Check FDA approval, ROHS rules, REACH registry, UL certification, and ASTM standards.

Prime sources from Ravago, SABIC, BASF, and DuPont.

What is the best plastic for car parts?

Car parts must endure heat, vibration, UV, and chemicals. One wrong plastic can cause failure.

Different car parts need specific polymers—engine bay uses PA66‑GF; interiors need ABS or ASA.

Dive Deeper: Match plastic to part location

| Car Component | Ideal Plastic | Performance Feature |

|---|---|---|

| Engine bay parts | PA66‑GF30, PEEK | Heat and load resistance[^9] |

| Dashboard panels | ABS, PC‑ABS, ASA | UV stability, appearance[^10] |

| Fuel system parts | HDPE, PVDF, PBT | Chemical permeability[^11] |

| Light housings | PC, PMMA | Optical clarity[^12] |

| HVAC components | PP, PC‑ABS | Lightweight durability[^13] |

See case studies from DuPont Automotive and Celanese.

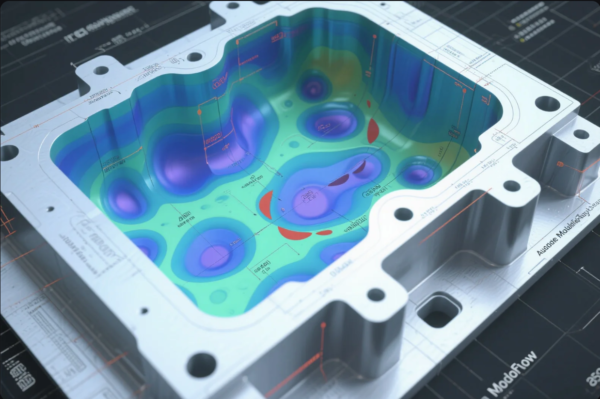

Simulations use Autodesk Moldflow and Siemens NX plastics.

How to determine what kind of plastic?

Many projects start with no clear direction.

Use a structured function-based matrix and validate through testing or simulation.

Dive Deeper: Function-Based Matrix

| Metric | Recommended Plastics | Application Example |

|---|---|---|

| Strength-to-weight | PA6‑GF, PP‑Talc | Drone parts, protective shrouds |

| Flexibility/vibration | TPU, TPE | Seals, grips |

| Chemical exposure | PVDF, PTFE, HDPE | Fuel lines, water meters |

| Optical clarity | PMMA, PC | Light covers, sensors |

| Anti-static | ABS + carbon, PBT, PPS | Electronics housings |

| Food/medical use | HDPE, PEI, POM | Cookware, diagnostics |

Use Curbell plastics selector and Polymer Database for comparisons.

Test in-house: heat, UV, salt-spray per ISO 105-A02 and melt flow per ISO 1133.

What is the most important consideration in designing plastics parts?

Even the best plastic fails if the design ignores material behavior.

Consider mold filling, shrinkage, DFM, wall thickness, ribs, draft angles.

Dive Deeper: Key Design Rules

| Design Feature | Best Practice |

|---|---|

| Wall thickness | Uniform 1.5–4 mm |

| Ribs | Rounded base, ≤3× wall height |

| Draft angles | Minimum 1–3° |

| Snap features | Filleted, simulate load |

We use CAD tools: SolidWorks Plastics, Protolabs guide, Fictiv DFM, and Autodesk Knowledge for design support.

FAQs

1. Can Prime help choose plastics?

Yes. Email designs to [email protected] for personalized guidance.

2. Are materials certified?

Yes. We provide ROHS, REACH, FDA, and UL-certified materials.

3. What is the lead time?

Samples: 7–10 days; Production: 2–4 weeks depending on quantity.

4. Can you provide custom logos and packaging?

Yes. We offer branded moldings and packaging per PakFactory specs.

5. Do you offer other services?

We handle CNC machining, stamping, casting, plastic molding, and fasteners.

Contact Us

🌐 Website: https://primecustomparts.com

📧 Email: [email protected]

We provide:

- Free technical consultations

- ISO 9001 certified production

- Fast quoting and global shipping

- Flexible volumes from prototypes to mass production

- Integrated service across plastics and metals

Conclusion

Right plastic choice = strong parts, lower cost, fewer failures.