How to Ensure Quality and Certification Compliance for Aluminum Set Screws?

The frustration of receiving substandard fasteners can compromise product integrity, safety, and regulatory compliance. Quality aluminum set screws must meet rigorous standards and certifications to ensure performance in critical applications, particularly in electrical and industrial environments.

Quality aluminum set screws must comply with industry standards including ISO 9001 for manufacturing processes, material specifications like ASTM B211 for aluminum alloys, and application-specific certifications such as UL and CSA for electrical components.

Before selecting a supplier for your aluminum set screws, understand the critical quality standards and certification requirements that will ensure your components meet both performance needs and regulatory obligations.

What Certifications Are Essential for Aluminum Set Screws in Electrical Applications?

The pain of non-compliant electrical components can lead to failed inspections, product recalls, and even liability issues. Aluminum set screws used in electrical applications require specific certifications to ensure safety and performance in these critical environments.

For electrical applications, aluminum set screws must meet UL (Underwriters Laboratories) and CSA (Canadian Standards Association) requirements when used in wire connectors, with strict adherence to material composition, plating specifications, and dimensional tolerances.

Dive-Deeper paragraph: The certification landscape for electrical components is complex and multifaceted, with requirements varying by region, application, and specific use case. Understanding the nuances of these certifications is essential for ensuring that aluminum set screws meet all necessary compliance requirements while delivering the performance characteristics needed for electrical applications.

Understanding UL Certification for Fasteners

UL certification is particularly important for fasteners used in electrical applications:

| — | ||||||||

|---|---|---|---|---|---|---|---|---|

| UL 486A-B | Wire Connectors | Material composition, plating, torque capability, conductivity | Laboratory testing | |||||

| UL 1059 | Terminal Blocks | Dimensional stability, thread integrity, conductivity | Physical testing | |||||

| UL 94 | Flammability | Fire resistance rating | Flame testing | |||||

| UL 746A | Polymeric Materials | Compatibility with insulation materials | Chemical testing |

CSA Certification Requirements

CSA certification parallels many UL requirements but with some distinct differences:

CSA C22.2 No. 65

This standard covers wire connectors and requires:

- Material Verification

- Aluminum alloy composition testing

- Plating thickness measurement

- Surface treatment evaluation

- Conductivity testing

- Mechanical Performance

- Torque testing

- Thread strength evaluation

- Point integrity assessment

- Vibration resistance

- Electrical Performance

- Current cycling tests

- Temperature rise measurements

- Contact resistance evaluation

- Dielectric strength testing

Field Inspection Considerations

It\’s important to note that field modifications to certified electrical assemblies are strictly regulated:

"UL and CSA DO NOT PERMIT ANY unauthorized field repair or modification to any connector bearing the UL or CSA logos. It is entirely the responsibility of the purchaser to obtain all of the approvals from the AHJ (Authority Having Jurisdiction) covering the application."

This requirement has significant implications for maintenance and repair operations, as explained by a senior electrical inspector I consulted: "The certification applies to the complete assembly as tested. Replacing even a single component like a set screw with a non-OEM part can invalidate the entire certification and create a code violation."

How Do Material Standards Ensure Aluminum Set Screw Quality?

The challenge of inconsistent material properties leads to unpredictable performance and premature failure. Aluminum set screws must conform to established material standards that define composition, mechanical properties, and heat treatment to ensure consistent quality.

Quality aluminum set screws typically use alloys like 2024-T4 or 7075-T6 that conform to ASTM B211 standards, specifying precise chemical composition, tensile strength (310-570 MPa depending on alloy), and hardness requirements to ensure consistent performance.

Dive-Deeper paragraph: The material specifications for aluminum set screws are foundational to their performance characteristics. These standards define not just the chemical composition but also the processing methods, heat treatments, and testing protocols that ensure the finished fasteners will perform as expected under their intended service conditions.

Aluminum Alloy Standards and Specifications

The primary standards governing aluminum alloys for fasteners include:

| — | ||||||||

|---|---|---|---|---|---|---|---|---|

| ASTM B211 | Aluminum Alloy Bar, Rod, and Wire | Chemical composition, mechanical properties, dimensional tolerances | 2024, 6061, 7075 | |||||

| ASTM B221 | Aluminum Alloy Extruded Bars, Rods, Wire | Extrusion quality, surface finish, straightness | 6061, 6063 | |||||

| ISO 6362 | Wrought Aluminum and Aluminum Alloys | International specifications for extruded products | Multiple alloys | |||||

| AMS 4117 | Aerospace Material Specification | High-performance requirements for aerospace applications | 7075-T73 |

Critical Material Properties

The performance of aluminum set screws depends on specific material properties:

Tensile Strength Requirements

Different applications require different strength levels:

| — | ||||||||

|---|---|---|---|---|---|---|---|---|

| 2024 | T4 | 470 | High-strength electrical, industrial | |||||

| 6061 | T6 | 310 | General purpose, corrosion resistance | |||||

| 7075 | T6 | 570 | Aerospace, high-performance | |||||

| 2011 | T3 | 380 | Free-machining, electrical |

Hardness Specifications

Surface hardness affects thread durability and point performance:

- Rockwell Hardness

- 2024-T4: B80-B85

- 6061-T6: B60-B65

- 7075-T6: B85-B90

- Surface Treatment Effects

- Anodizing: Increases surface hardness

- Tin plating: Provides lubricity

- Hard coating: Enhances wear resistance

Material Certification Documentation

Quality aluminum set screws should be accompanied by material certification that includes:

- Mill Test Reports

- Chemical composition analysis

- Mechanical property test results

- Heat treatment verification

- Lot traceability information

- Compliance Statements

- Applicable standards conformance

- Special process certifications

- RoHS/REACH compliance status

- Country of origin declaration

A materials engineer at a major fastener testing laboratory explained: "The material certification is your assurance that the fastener starts with the right foundation. Without proper material compliance, no amount of precision manufacturing can create a quality product."

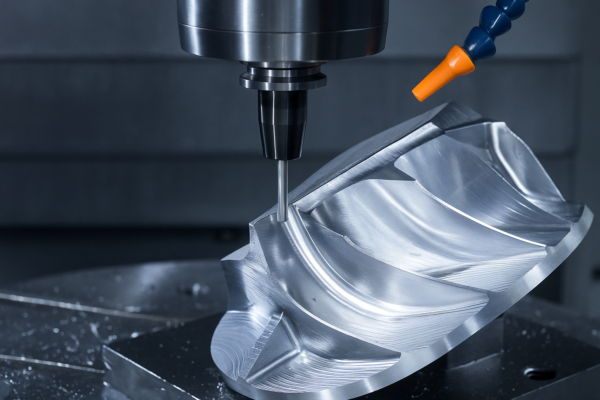

What Manufacturing Standards Govern Aluminum Set Screw Production?

The problem of dimensional inconsistency and manufacturing defects leads to assembly difficulties, joint failures, and performance issues. Aluminum set screws must be manufactured according to established standards that control critical dimensions, thread specifications, and surface quality.

Manufacturing standards for aluminum set screws include ASME B18.3 for socket products, ASME B1.1 for unified threads, and ISO 4026-4029 for socket set screws, with quality systems typically certified to ISO 9001 to ensure consistent production processes.

Dive-Deeper paragraph: The manufacturing standards for aluminum set screws establish the framework for dimensional consistency, thread form accuracy, and surface quality that directly impact functionality. These standards work in conjunction with quality management systems to ensure that production processes consistently deliver fasteners that meet all specified requirements.

Dimensional and Thread Standards

The primary standards governing set screw dimensions and threads include:

| — | ||||||||

|---|---|---|---|---|---|---|---|---|

| ASME B18.3 | Socket Cap, Shoulder, Set Screws | Head dimensions, drive features, lengths | Class 2A/2B | |||||

| ASME B1.1 | Unified Inch Screw Threads | Thread profile, pitch, major/minor diameters | 2A external, 2B internal | |||||

| ISO 4026 | Hexagon Socket Set Screws with Flat Point | Dimensions, tolerances, mechanical properties | 6g/6H | |||||

| ISO 4027 | Hexagon Socket Set Screws with Cone Point | Point geometry, thread length, socket size | 6g/6H | |||||

| ISO 4028 | Hexagon Socket Set Screws with Dog Point | Dog point dimensions, thread specifications | 6g/6H | |||||

| ISO 4029 | Hexagon Socket Set Screws with Cup Point | Cup geometry, depth, thread specifications | 6g/6H |

Manufacturing Process Controls

Quality aluminum set screw production requires controls at each manufacturing stage:

Raw Material Processing

- Material Verification

- Incoming material inspection

- Alloy verification testing

- Dimensional checking

- Surface condition assessment

- Cutting and Forming

- Precision cutting to length

- Cold heading or machining

- Drive feature formation

- Point geometry creation

Thread Production

Thread quality directly impacts set screw performance:

| — | ||||||||

|---|---|---|---|---|---|---|---|---|

| Thread Rolling | Higher strength, better grain flow | Limited to certain sizes | Surface preparation critical | |||||

| Thread Cutting | Precise threads, any material hardness | Interrupted grain flow | Tool sharpness, lubricant | |||||

| Thread Grinding | High precision, hardened materials | Slower production, higher cost | Wheel dressing, heat control |

Surface Treatments

Surface treatments affect both appearance and performance:

- Cleaning Processes

- Degreasing

- Etching

- Descaling

- Passivation

- Plating Operations

- Zincate pretreatment

- Copper strike layer

- Tin plating

- Wax application

Quality Management Systems

Manufacturing quality is ensured through comprehensive quality systems:

ISO 9001 Requirements

ISO 9001 certification ensures:

- Process Control

- Documented procedures

- Process monitoring

- Statistical process control

- Corrective action systems

- Inspection Protocols

- Incoming material inspection

- In-process checks

- Final inspection

- Lot traceability

A quality manager at a fastener manufacturing facility noted: "ISO 9001 isn\’t just about having a certificate on the wall. It\’s about implementing systems that prevent defects rather than just detecting them. For aluminum set screws, this means controlling every variable from raw material to final packaging."

How Do Environmental Compliance Standards Impact Aluminum Set Screws?

The challenge of meeting increasingly stringent environmental regulations affects material selection, manufacturing processes, and global marketability. Aluminum set screws must comply with various environmental standards to ensure they can be legally sold and used in target markets.

Environmental compliance for aluminum set screws includes RoHS (Restriction of Hazardous Substances) for lead-free composition, REACH (Registration, Evaluation, Authorization of Chemicals) for safe material usage, and conflict minerals reporting for ethical sourcing.

Dive-Deeper paragraph: Environmental compliance has become increasingly important in the fastener industry, with regulations varying by region and application. Understanding these requirements is essential not only for legal compliance but also for meeting customer expectations regarding environmental responsibility and sustainable manufacturing practices.

RoHS Compliance Requirements

The Restriction of Hazardous Substances directive limits the use of specific hazardous materials:

| — | ||||||||

|---|---|---|---|---|---|---|---|---|

| Lead (Pb) | 0.1% | Present in some aluminum alloys (e.g., 2011) | Use RoHS-compliant alloys or obtain exemptions | |||||

| Mercury (Hg) | 0.1% | Not typically present | Verification testing | |||||

| Cadmium (Cd) | 0.01% | Potential plating contaminant | Certified plating processes | |||||

| Hexavalent Chromium (Cr6+) | 0.1% | Potential in conversion coatings | Alternative treatments | |||||

| PBBs/PBDEs | 0.1% | Not relevant to metal fasteners | Documentation only | |||||

| Phthalates (DEHP, BBP, DBP, DIBP) | 0.1% | Potential in packaging | Compliant packaging materials |

REACH Compliance

REACH regulations address a broader range of chemicals:

Substances of Very High Concern (SVHC)

- SVHC Identification

- Regular updates to candidate list

- Supplier communication requirements

- Threshold reporting at 0.1% w/w

- Notification obligations

- Documentation Requirements

- Material declarations

- Safety data sheets

- Supply chain communication

- Record retention

Conflict Minerals Reporting

Ethical sourcing requirements affect the supply chain:

- Regulated Minerals

- Tin (relevant to plated aluminum set screws)

- Tungsten (potentially in tooling)

- Tantalum (not typically relevant)

- Gold (not typically relevant)

- Due Diligence Requirements

- Supply chain mapping

- Smelter identification

- Country of origin determination

- Annual reporting

Regional Variations in Environmental Compliance

Requirements vary significantly by region:

| — | ||||||||

|---|---|---|---|---|---|---|---|---|

| European Union | RoHS, REACH | Most comprehensive | Declaration of Conformity | |||||

| United States | TSCA, Prop 65 | State-level variations | Material disclosure | |||||

| China | China RoHS | Labeling requirements | Compliance marking | |||||

| Japan | J-MOSS | Product categories | Confirmation forms |

A regulatory compliance specialist I interviewed explained: "Environmental compliance for fasteners isn\’t optional anymore—it\’s a baseline requirement for doing business globally. Companies need to build compliance into their product development and supplier qualification processes rather than treating it as an afterthought."

How Are Aluminum Set Screws Tested and Inspected for Quality Assurance?

The risk of receiving non-conforming fasteners can lead to assembly problems, joint failures, and product recalls. Comprehensive testing and inspection protocols ensure that aluminum set screws meet all specified requirements before they reach your production line.

Quality assurance for aluminum set screws includes dimensional inspection using precision measuring equipment, material verification through chemical and physical testing, mechanical property validation including hardness and tensile strength, and surface treatment evaluation.

Dive-Deeper paragraph: The testing and inspection of aluminum set screws involves a multi-layered approach that examines both physical attributes and performance characteristics. These processes are designed to verify compliance with all applicable standards and specifications while ensuring that the fasteners will perform as expected in their intended applications.

Dimensional Inspection Methods

Precision measurement is fundamental to fastener quality:

| — | ||||||||

|---|---|---|---|---|---|---|---|---|

| Thread Dimensions | Thread gages, optical comparators | Go/No-Go, Class 2A/2B or 6g/6H | ANSI/ASQ Z1.4 | |||||

| Length | Digital calipers, micrometers | Specified tolerance (typically ±0.5mm) | ANSI/ASQ Z1.4 | |||||

| Point Geometry | Optical comparators, profile projectors | Drawing specifications | ANSI/ASQ Z1.4 | |||||

| Drive Feature | Socket gages, optical measurement | Go/No-Go, dimensional tolerance | ANSI/ASQ Z1.4 |

Material Verification Testing

Confirming material composition and properties:

Chemical Analysis Methods

- Spectroscopic Analysis

- X-ray fluorescence (XRF)

- Optical emission spectroscopy (OES)

- Energy dispersive X-ray (EDX)

- Wet chemical analysis

- Physical Property Testing

- Hardness testing (Rockwell, Brinell)

- Tensile testing

- Microstructure examination

- Conductivity measurement

Functional Performance Testing

Evaluating how fasteners will perform in use:

- Mechanical Testing

- Torque-tension relationship

- Drive strength

- Thread stripping strength

- Point penetration capability

- Environmental Testing

- Salt spray resistance

- Humidity exposure

- Temperature cycling

- Corrosion testing

Surface Treatment Evaluation

Assessing the quality of platings and coatings:

| — | ||||||||

|---|---|---|---|---|---|---|---|---|

| Thickness Measurement | Plating thickness | Specification minimum | ASTM B659 | |||||

| Adhesion Testing | Coating adhesion | No peeling or flaking | ASTM B571 | |||||

| Salt Spray Testing | Corrosion resistance | Hours to white/red rust | ASTM B117 | |||||

| Appearance Evaluation | Visual characteristics | Uniform appearance | Customer specification |

Quality Documentation

Comprehensive documentation provides evidence of compliance:

- Inspection Reports

- Dimensional results

- Material verification

- Surface treatment evaluation

- Functional testing

- Certificates of Conformance

- Standards compliance

- Material certification

- Process certifications

- Lot traceability

A quality assurance manager at a fastener manufacturing facility shared this insight: "The documentation is just as important as the physical testing. Without proper records that demonstrate compliance, even the highest quality fasteners can be rejected by quality-conscious customers who need evidence for their own compliance systems."

Contact Us

📧 Email us: [email protected]🌐 Visit: https://primecustomparts.com

Get a free quote, custom tool configuration, and fast delivery worldwide. Every order comes with setup support.

Conclusion

Quality aluminum set screws require compliance with multiple standards including UL/CSA for electrical applications, ASTM material specifications, ASME/ISO dimensional standards, and environmental regulations like RoHS and REACH, all verified through comprehensive testing and inspection protocols.