How to Get Custom Precision Plastic Parts Manufactured Efficiently?

Custom plastic sourcing is often confusing due to design issues or miscommunication.

Custom plastic parts1 require the right design, correct material, and optimal process. Clear planning prevents quality issues2 and costly delays.

Getting the right plastic part1 involves many steps — design, material choice, production, and quality inspection2. In this guide, I’ll walk you through each of them.

What Should You Know About Custom Plastic Part Production and Material Selection?

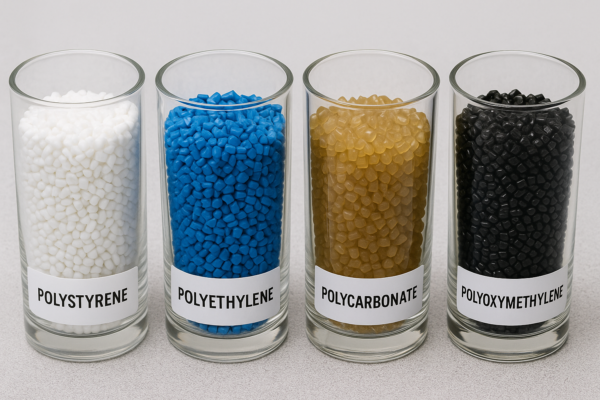

Designers and buyers often get stuck choosing plastic types1.

Each plastic material2 behaves differently under stress, heat, and machining. Picking the wrong one can cause deformation, breakage, or high costs.

Understanding Common Plastics and Their Applications

Different industries require1 different plastic types2. For example:

| Material | Properties | Best Applications |

|---|---|---|

| ABS | Strong, impact-resistant1 | Electrical housings, auto interiors |

| Nylon | High wear resistance2 | Bushings, gears, moving parts |

| POM (Acetal) | Low friction, stable dimensions | Gears, precision mechanical parts |

| PC | Transparent, UV resistant | Machine guards, lenses |

| PP | Chemical resistant, flexible | Laboratory components, fluid systems |

I once helped a client in aerospace who insisted on ABS, but the part needed chemical resistance. We switched to PPS, which performed better. This saved thousands in failures. You can read more about material selection or refer to polymer behavior.

We also source materials from top resin brands such as SABIC, BASF, and Celanese. If you’re targeting flammability certifications, materials must comply with UL 94 standards.

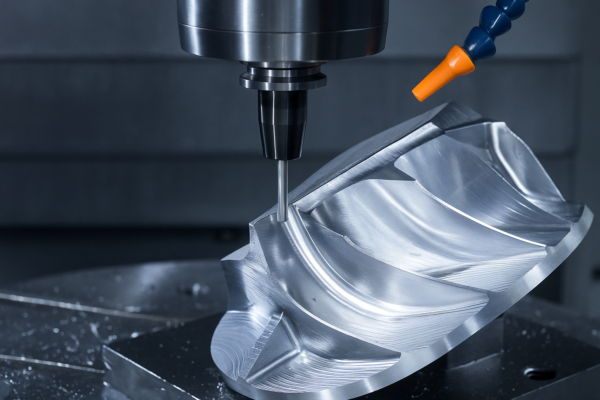

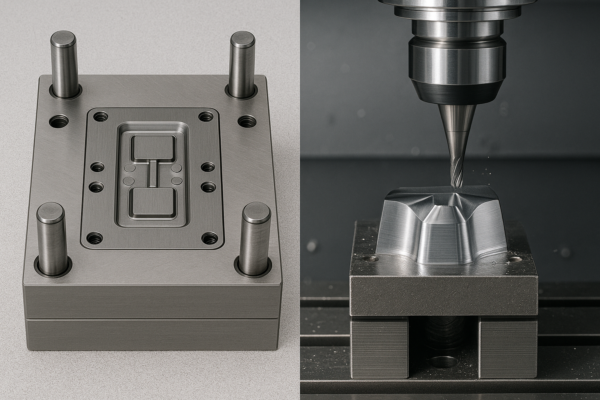

Injection Molding vs CNC Machining: Which One Should You Choose?

Many buyers confuse these methods and pick the wrong one for their order size.

Injection molding1 suits mass production. CNC plastic machining2 fits prototypes or tight tolerances. Knowing the difference saves cost and time.

Compare CNC Machining vs Injection Molding for Plastics

We work with both technologies1 daily2. Here’s what you need to know:

| Feature | Injection Molding | CNC Machining |

|---|---|---|

| Setup Time | Longer (due to tooling) | Very short |

| Part Cost | Low for bulk, high for samples | Higher per unit, no mold needed |

| Tolerance Control1 | Moderate (±0.1 mm) | Very tight (±0.01 mm possible) |

| Material Flexibility2 | Limited to moldable plastics | Almost any plastic rod or sheet |

| Surface Finish | Mold defined | Tool-path visible, can be polished |

| Lead Time | 2–5 weeks after mold build | 3–5 days on demand |

You can learn more in Protolabs’ injection guide or Xometry’s CNC vs Molding comparison.

Our factory at Prime offers both services with fast transitions. One German client needed 10 prototypes — we delivered CNC samples1 in 3 days, then mass produced with injection molding2 in 20 days.

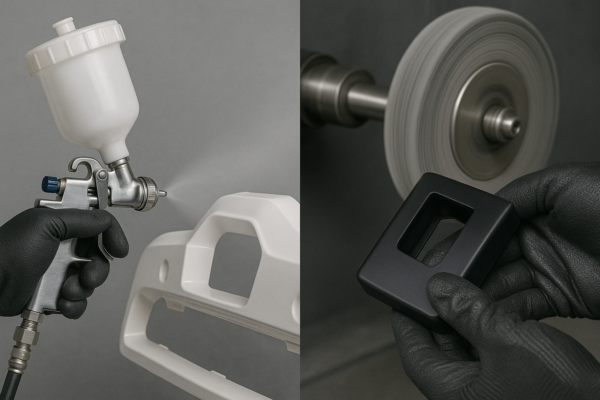

Why Surface Finishing and Quality Control Matter So Much?

Buyers often focus on dimensions and overlook surface finish and part consistency.

Surface defects1, poor assembly fit2, or color mismatches can cause rejection, especially in consumer-facing or precision-use applications.

Different Finishes Serve Different Needs

Surface finish1 isn’t just visual — it’s functional. Here’s how we help clients choose the right finish2:

| Finish Type | Description | Ideal For |

|---|---|---|

| Polishing | Glossy and smooth, optical clarity1 | Covers, display windows |

| Texturing | Matte feel, scratch resistant2 | Enclosures, handheld parts |

| Painting | Custom color, logo integration | Branding, aesthetics |

| Sandblasting | Uniform roughness | Industrial or grip-related parts |

You can explore visual standards like VDI textures or browse Fictiv’s finish gallery.

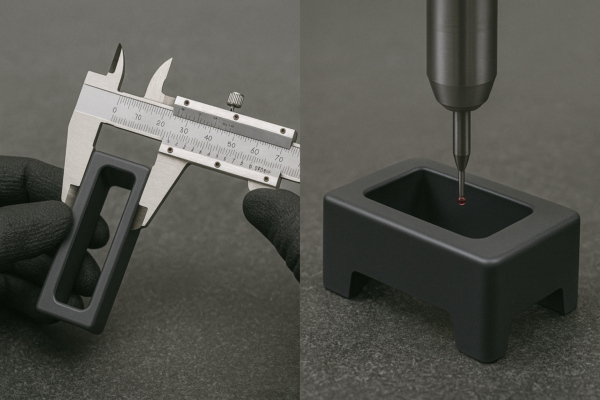

Our Quality Control System Ensures Repeatable Precision

We use:

We also follow best practices in SPC methods to ensure process stability. Each batch is traceable and certified.

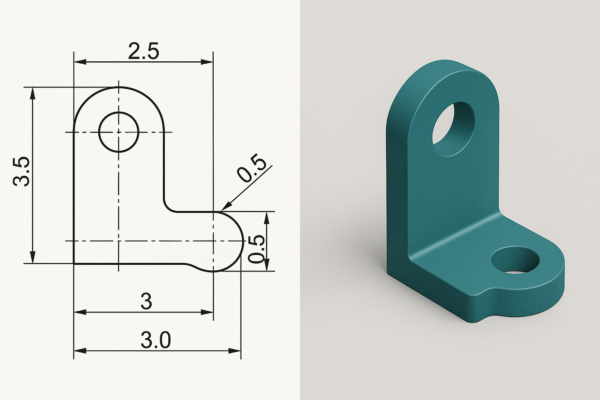

How to Prepare Drawings, Request Quotes & Ensure Fast Turnaround?

Late delivery is often caused by incomplete drawings1 or unclear specifications.

Preparing drawings properly, choosing the right supplier, and providing full order details2 can reduce quoting and production time by days.

Use This Checklist to Speed Up Everything

Before sending RFQs:

- Provide 2D PDF + 3D STEP1 files

- List materials, quantity, and finishes

- Mark tolerance zones in red2

- Indicate inserts, threads, and packaging needs

If you’re unsure, use tools like Fusion360, or review Xometry’s design rules. We also suggest checking Pantone charts for color-matched plastic.

We typically quote within 24 hours and ship CNC prototypes1 in 3–5 working days. For tooling projects, our mold flow analysis2 helps predict part defects early.

Our clients ship globally using FedEx, DHL, or UPS.

We follow export standards including:

- Moisture-proof bags1

- Foam protection

- Custom crates on pallets (ISPM 15 ready)2

FAQs: Custom Plastic Parts Manufacturing

Q1: What’s your minimum order quantity1 (MOQ)?

CNC: 1 unit. Injection: 100–500 units.

Q2: Can you help improve my CAD design?

Yes, we provide free DFM analysis2.

Q3: What tolerances can you hold?

CNC: ±0.01 mm. Molding: ±0.05–0.1 mm.

Q4: What materials do you support?

ABS, PC, POM, PEEK, Nylon, and more. View them all

Q5: Can you provide RoHS/FDA certificates1?

Yes. All batches are traceable and certified.

Q6: What is your lead time2?

Samples: 3–5 days. Production: 2–3 weeks.

Q7: Do you support custom colors?

Yes, matched by Pantone.

Q8: Where do you export?

USA, Europe, Middle East, Australia, and more.

Q9: What surface finishes1 can I request?

VDI textures2, matte/smooth, silk-screening, and painting.

Q10: How can I get a quote fast?

Send your drawings to [email protected].

Glossary: Common Terms in Plastic Part Manufacturing

| Term | Meaning |

|---|---|

| DFM | Design for Manufacturability1 |

| CMM | Coordinate Measuring Machine2 |

| UL94 | Flammability rating for plastics |

| Tolerance | Allowed dimension variation |

| Sink Mark | Surface depression caused by uneven cooling |

| VDI Texture | Standard texture applied to molds |

| STEP File | 3D CAD file format for machining |

Contact Prime Now

Want your custom plastic parts delivered fast, with consistent quality?

📧 Email us: [email protected]

🌐 Visit: https://primecustomparts.com

We offer:

- Free engineering review1

- Competitive quotes within 24 hours

- Rapid prototyping & certified production2

- Global delivery with export-grade packaging

Conclusion

Custom plastic parts need smart decisions. Prime makes them fast, precise, and stress-free.