How to make screw holes in metal?

Creating screw holes in metal is a crucial step for assembling parts, mounting components, or fastening materials securely. Whether you’re working with thin sheet metal or thicker steel, the process requires the right tools and approach to ensure a clean, strong, and accurate hole for your screw.

Snippet paragraph: You can make screw holes in metal using drills, taps, or self-drilling screws, depending on the material thickness and precision required.

In this article, we’ll cover several methods to create screw holes in metal, how to tap threads, when to use self-drilling screws, and how to do it without a drill.

How to create a screw hole in metal?

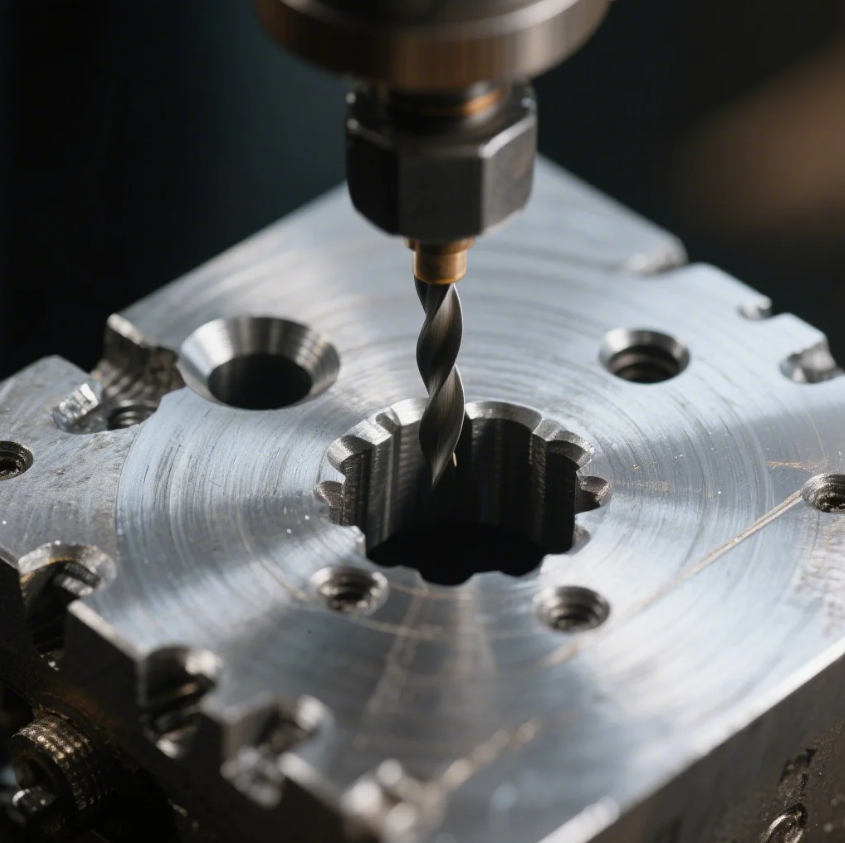

The most common way to create a screw hole in metal is by using a power drill and the correct size drill bit. This allows you to create a precise, clean hole that can accommodate various fasteners such as screws, bolts, or rivets.

Snippet paragraph: Creating screw holes in metal typically involves using a drill with a metal bit sized for the fastener you plan to use.

Step-by-Step Process:

- Choose the Right Drill Bit: Use a high-speed steel (HSS) or cobalt drill bit designed specifically for metal. Match the bit size to the diameter of your screw.

- Mark the Spot: Use a pencil or center punch to mark the exact spot for your hole. A punch helps prevent the drill bit from slipping.

- Secure the Metal: Clamp the metal piece securely to a workbench or other stable surface to prevent movement.

- Drill the Hole: Drill slowly and steadily at a low to medium speed. Apply consistent pressure and periodically pause to let the metal cool down.

- Deburr the Hole: Use a deburring tool or file to smooth out the edges of the hole and remove any metal shavings.

Pro Tip:

- For harder metals, use cutting oil to reduce heat buildup and prolong the life of your drill bit.

How do you tap a screw hole in metal?

Tapping a screw hole means creating internal threads in a pre-drilled hole so that a screw or bolt can securely grip the metal. This process is essential when you’re not using self-tapping or self-drilling screws and need a precise, reusable threaded connection.

Snippet paragraph: Tapping a hole in metal creates threads inside the drilled hole so that screws or bolts can be fastened securely.

Tools Needed:

- Drill and bit (for pilot hole)

- Tap set (tap wrench + tap)

- Cutting fluid or oil

Step-by-Step Process:

- Drill the Pilot Hole: Use the correct size drill bit based on the thread size you want to cut. This is typically smaller than the outer diameter of the screw.

- Apply Cutting Oil: Add a drop of cutting oil to the hole to reduce friction and heat during the tapping process.

- Insert the Tap: Align the tap vertically with the hole and turn it slowly with a tap wrench.

- Cut the Threads: Rotate the tap clockwise for about a half-turn, then reverse it slightly to break the chip. Continue this motion until the threads are fully formed.

- Clean the Threads: Remove the tap and clean the hole of any metal shavings.

Tap Drill Chart Example:

| Screw Size | Drill Size for Tap |

|---|---|

| M4 × 0.7 | 3.3 mm |

| M6 × 1.0 | 5.0 mm |

| 1/4"-20 UNC | #7 (0.201") |

How to use self-drilling screws in metal?

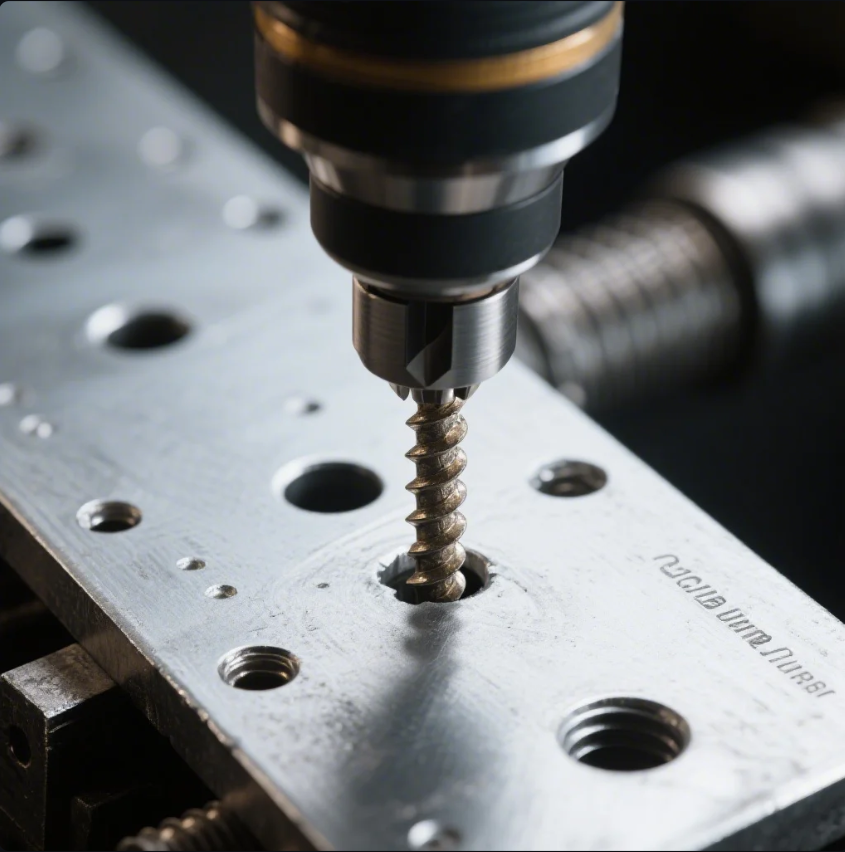

Self-drilling screws combine the functions of drilling and fastening in one action. They have a special tip that resembles a drill bit, allowing them to pierce through metal without needing a pilot hole.

Snippet paragraph: Self-drilling screws can create their own holes in metal and secure themselves without pre-drilling, saving time and effort.

How to Use:

- Mark the Location: Use a center punch or marker to identify where the screw will go.

- Align the Screw: Position the self-drilling screw on the marked spot and ensure it’s perpendicular to the surface.

- Drive the Screw: Use a power driver or screwdriver to insert the screw into the metal. The drill tip will cut into the material and the threads will grip it securely.

- Finish Tightening: Once the screw has drilled through and created threads, continue driving it until the head is flush with the surface.

Advantages:

- No need for pre-drilling.

- Fast and efficient installation.

- Ideal for sheet metal, aluminum, and other thin metals.

How to make a hole in metal without a drill?

If you don’t have access to a drill, you can still make a hole in metal using a few alternative tools and techniques. While not as fast or precise, these methods can work in DIY and emergency situations.

Snippet paragraph: You can make a hole in metal without a drill using tools like a nail and hammer, a punch, or a rotary tool.

Methods to Try:

-

Nail and Hammer (for Thin Metal):

- Place the metal on a firm surface.

- Position a hardened steel nail where you want the hole.

- Strike the nail with a hammer until it punctures the metal.

- Widen the hole by tapping the nail further or using a metal file.

-

Manual Center Punch:

- Use a center punch and hammer to dent the metal.

- Repeatedly strike the same point to penetrate the surface.

- Use a round file to enlarge or shape the hole.

-

Rotary Tool (Dremel):

- Equip your rotary tool with a metal cutting bit or grinding attachment.

- Carefully grind through the metal to create or widen a hole.

- Best for small or thin metal projects.

-

Metal Hole Punch:

- A handheld or bench-mounted metal hole punch is effective for soft sheet metal.

- Simply align the tool and squeeze or press to punch a clean hole.

Considerations:

- These methods are best for soft or thin metals.

- Always wear safety gear like gloves and goggles.

- Clamp your material to prevent it from shifting while working.

Conclusion

Making screw holes in metal can be done using various techniques, from drilling and tapping to using self-drilling screws or manual alternatives. For high-precision applications, drilling and tapping are the most reliable methods. For quicker, no-fuss fastening, self-drilling screws offer a fast solution. And when you don’t have a drill, tools like a punch, rotary tool, or even a hammer and nail can get the job done on thinner metals.

Choose the method that best suits your material, project type, and available tools to ensure strong, clean, and lasting results.