How to Select the Right High-Pressure Neck Ring: Specifications and Industry Standards?

Choosing the right high-pressure cylinder neck ring isn’t just about dimensions—it’s about global safety, lifetime reliability, and legal compliance. For OEMs and procurement teams, a single specification error can lead to gas leaks, regulatory failures, or customer returns. That’s why world-class gas system suppliers and cylinder manufacturers trust certified, experienced partners who follow international standards.

A well-chosen neck ring means better sealing, longer cylinder service, and lower maintenance. From thread standards to material choices, pressure ratings, and custom marking, this guide covers every critical detail—so your next order passes every inspection and field test.

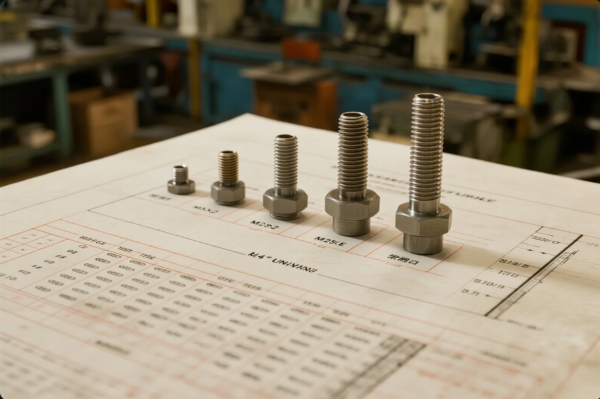

Detailed Overview of Cylinder Thread Standards (M25×2, 17E, 3/4″UNF, etc.)

Cylinder neck thread type determines what valve, regulator, or cap will fit your product. Mismatched threads are a primary source of installation failure and leaks. Each global market relies on its own dominant standards.

Popular thread types include M25×2 (Europe/Asia), 17E (EN standard), 3/4" UNF (USA/UK), 25E, and G3/4 BSP (plumbing/gas).

Buyers and engineers should reference:

- European Industrial Gases Association

- British Compressed Gases Association

- Compressed Gas Association (CGA)

- DOT and ISO regulations

Common problems from mismatched threads include thread stripping, leak paths, and regulatory recall.

| Thread Standard | Region | Typical Application | Official Reference |

|---|---|---|---|

| M25×2 | EU, Asia | Industrial/medical gases | IHB metric threads |

| 17E | Europe | Medical/food cylinders | Cylinder Valves |

| 3/4″UNF | USA/UK | DOT industrial cylinders | Engineering Toolbox |

| 25E | LPG/propane | Automotive, BBQ, camping | Gascon |

| G3/4 | Global | Plumbing/gas pipes | Engineers Edge |

For large projects or multi-country export, always confirm the local thread and regulatory needs.

Comparing Carbon Steel, Stainless Steel, and Aluminum Alloy Neck Rings

The right material for your neck ring depends on safety, corrosion, weight, and compliance. Top manufacturers like Luxfer Gas Cylinders, Worthington Industries, and Faber select alloys based on field risk and regulatory audits.

**- Carbon steel: Used for most industrial cylinders. Needs plating (zinc/nickel) for anti-corrosion.

- Stainless steel: Ideal for medical, food, or marine use—resistant to rust and easy to clean.

- Aluminum alloy: Lightweight, non-rusting, great for SCUBA, rescue, and aviation cylinders.**

Consult reputable material sources:

| Material | Pros | Ideal Application | More Info |

|---|---|---|---|

| Carbon steel | Strong, affordable, easy to machine | Industrial, transport, regulated markets | Metals Supermarkets |

| Stainless steel | Rust-proof, food/medical approved | Marine, medical, food, clean gases | AZoM |

| Aluminum alloy | Light, non-magnetic, no corrosion | SCUBA, aviation, portable medical, high mobility | Matmatch |

Prime can provide full material certificates with each batch.

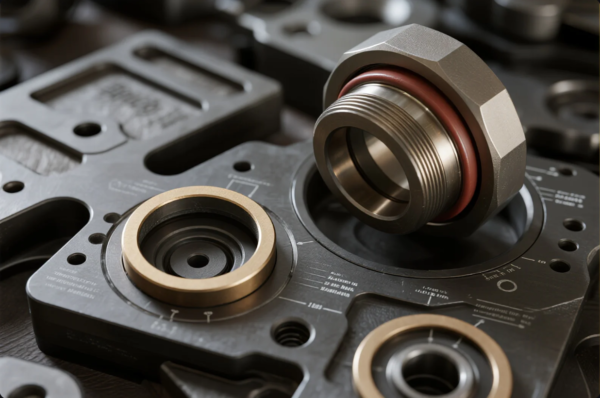

Pressure Ratings and Sealing Methods: Choosing the Correct Neck Ring

Using a neck ring with too low a pressure rating or the wrong seal risks both product recall and safety incidents. All reputable cylinder manufacturers follow ISO 9809, EN 1442, or DOT 3AA standards.

Standard neck rings must withstand working pressures from 150 to 300 bar (2,000–4,500 psi) or higher. Sealing methods include metal-to-metal, O-ring, or PTFE gasket, all verified by pressure and leak testing.

Learn more about sealing and pressure requirements:

- Sealingsolutions.com technical library

- Engineering Edge calculators

- Eurofins hydrostatic test services

| Sealing Type | Best Use | Max Pressure | Field Reference |

|---|---|---|---|

| Metal-to-metal | Industrial, transport | 300 bar+ | Cole Parmer |

| O-ring/gasket | Medical, food, light | 150–250 bar | Apple Rubber |

| PTFE insert | High-purity, chem | 250 bar | Chemours Teflon |

Custom Logo and Branding Options for Cylinder Neck Rings

In regulated and high-value markets, traceability, anti-counterfeiting, and brand visibility are mandatory. Customers expect logo marking, QR codes, and batch traceability on every component.

Prime offers laser etching, dot peen marking, color powder coating (PPG), anodizing (APT Metal), and even RFID embedding (HID Global). We support full regulatory compliance for all international markets.

For large fleets, asset management systems, IoT logistics, and digital QR code scanning (GS1) make traceable marking a necessity.

| Branding Option | Technology | Compliance | Supply Chain Use Case |

|---|---|---|---|

| Laser logo | Fiber/CO₂ laser | DOT, EN, ISO | Counterfeit prevention, corporate branding |

| QR/barcode | Laser/inkjet | FDA, EU MDR | Batch recall, asset management, logistics tracking |

| Color band | Powder coat, anodize | EU food, SCUBA | Fast field ID, market/region separation |

| RFID/NFC | Tag inlay, sticker | Custom | Automated check-in/check-out, high-value assets |

FAQs: Cylinder Neck Ring Selection

Can you match any international thread or marking requirement?

Yes. Prime manufactures M25×2, 17E, 3/4″UNF, and all other major global standards. We support custom branding, QR/barcodes, and country-of-origin marks.

What material is best for marine or food use?

Stainless steel or aluminum with passivation for maximum corrosion resistance. All with EN 10204 3.1 certificates.

How do I confirm pressure rating and compliance?

We provide full SGS, Intertek, BV certificates with every batch. See more at Eurofins.

Can I order urgent samples or custom bulk orders?

Yes. Prime supports express shipping via DHL, FedEx, and UPS, with digital batch tracking and real-time production updates.

Contact Us

Source certified, custom neck rings for your global projects—fast, reliable, and ready for any audit.

- Website: https://primecustomparts.com/

- Email: [email protected]

Conclusion

A perfect neck ring is engineered, tested, and traceable—never guessed. Rely on Prime for certified neck rings with global compliance, custom branding, and fast delivery to every region.