How to Source Custom Aluminum Set Screws for Wholesale Manufacturing?

The frustration of finding reliable suppliers for custom aluminum set screws can delay production timelines and compromise product quality. Manufacturers need dependable sourcing strategies to secure high-quality, customized fasteners that meet exact specifications while maintaining cost efficiency.

Custom aluminum set screws can be sourced through specialized fastener manufacturers who offer material options (2024, 6061, 7075 alloys), thread customization (metric/imperial), point style variations (cup, flat, oval, dog), and surface treatments (anodizing, tin plating) with MOQs typically starting at 5,000-10,000 pieces.

Before committing to a supplier for your custom aluminum set screws, consider these essential factors that will ensure you receive exactly what your application requires while maximizing value.

What Customization Options Are Available for Aluminum Set Screws?

The pain of using standard fasteners that don\’t quite meet your requirements leads to compromised performance and design limitations. Custom aluminum set screws offer numerous modification possibilities to perfectly match your specific application needs.

Aluminum set screws can be customized by alloy selection (2024 for strength, 6061 for corrosion resistance), thread specifications (UNC/UNF/metric), point style (cup, flat, oval, dog), drive type (hex socket, slotted), and surface treatments (anodizing, plating, waxing).

Dive-Deeper paragraph: The customization possibilities for aluminum set screws extend far beyond basic dimensions and thread specifications. When examining the full spectrum of available options, manufacturers can fine-tune virtually every aspect of these fasteners to optimize performance in specific applications. This level of customization requires understanding the trade-offs between various options and their impact on functionality, cost, and lead time.

Material Alloy Selection

The choice of aluminum alloy fundamentally affects performance characteristics:

| — | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2024-T4 | 470 | Moderate | Good | Electrical, high-strength | 1.2x | |||||||

| 6061-T6 | 310 | Excellent | Excellent | General purpose, corrosive environments | 1.0x | |||||||

| 7075-T6 | 570 | Good | Fair | Aerospace, high-performance | 1.5x | |||||||

| 2011-T3 | 380 | Moderate | Excellent | High-precision, free-machining | 1.3x | |||||||

| 5052-H32 | 230 | Excellent | Good | Marine, food processing | 1.1x |

Thread Customization Options

Thread specifications can be tailored to application requirements:

Thread Form Options

- Unified National Coarse (UNC)

- Larger thread pitch

- Greater tolerance for contamination

- Easier assembly

- Common sizes: #4-40 through 1/2-13

- Unified National Fine (UNF)

- Smaller thread pitch

- Higher tensile strength

- Better vibration resistance

- Common sizes: #4-48 through 1/2-20

- Metric Threads

- ISO metric thread standards

- Global compatibility

- Common sizes: M3 through M12

- Available in coarse and fine pitches

- Custom Thread Profiles

- Modified flank angles

- Specialized thread forms

- Application-specific designs

- Proprietary profiles for unique requirements

Point Style Variations

The point style significantly affects functionality:

| — | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Cup Point | Indentation/friction | Moderate | Limited | Maximum holding power | ||||||

| Flat Point | Surface pressure | Minimal | Good | Precise positioning, soft materials | ||||||

| Oval Point | Partial indentation | Low | Good | Frequent adjustment, moderate holding | ||||||

| Dog Point | Positive engagement | None | Excellent | Alignment, anti-rotation | ||||||

| Half-Dog Point | Partial engagement | Low | Good | Semi-permanent positioning | ||||||

| Extended Point | Deep engagement | Varies | Limited | Special alignment needs |

Drive Type Options

The drive feature affects installation torque and tool accessibility:

Hex Socket (Allen)

- Standard Hex Socket

- Common sizes: 0.050" through 3/8"

- Metric options: 1.5mm through 10mm

- Recessed drive for clean appearance

- Higher torque capability than slotted

- Hex Socket with Pilot Recess

- Enhanced tool engagement

- Reduced cam-out risk

- Higher torque capability

- Premium manufacturing cost

Slotted Drive

- Standard Slot

- Simple tool requirements

- Limited torque capability

- Susceptible to cam-out

- Lower manufacturing cost

- Cross Slot

- Improved torque transfer

- Reduced cam-out

- Multiple tool options

- Moderate manufacturing cost

A product design engineer I consulted with explained: "The drive type selection is often overlooked, but it can significantly impact both assembly efficiency and long-term serviceability. For high-volume production, investing in optimized drive features can yield substantial labor savings over the product lifecycle."

How to Evaluate and Select Aluminum Set Screw Manufacturers?

The challenge of finding reliable manufacturers who can consistently deliver quality custom aluminum set screws at competitive prices can be overwhelming. A systematic evaluation process helps identify suppliers who meet your specific requirements for quality, customization, and service.

Select aluminum set screw manufacturers based on ISO 9001 certification, material sourcing transparency, customization capabilities, minimum order quantities (typically 5,000-10,000 pieces for custom items), lead times (4-8 weeks for custom orders), and quality control processes.

Dive-Deeper paragraph: The selection of a manufacturing partner for custom aluminum set screws requires a comprehensive evaluation process that goes beyond basic pricing considerations. The right manufacturer becomes an extension of your own production capabilities, with their quality systems, technical expertise, and reliability directly impacting your product performance and customer satisfaction.

Manufacturing Capability Assessment

Evaluate potential suppliers based on their production capabilities:

| — | ||||||||

|---|---|---|---|---|---|---|---|---|

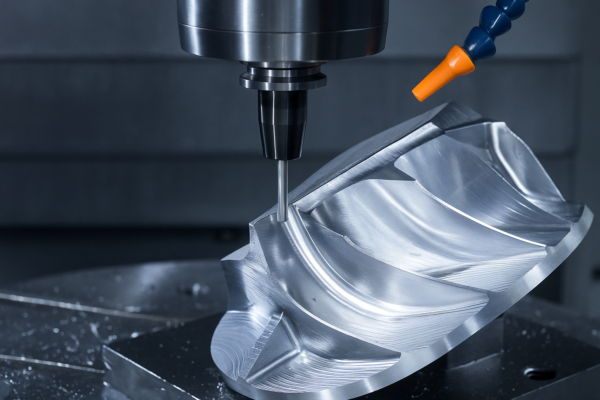

| Equipment | CNC machining centers, thread rolling, grinding | Facility tour, equipment list | High | |||||

| Capacity | Monthly production volume, shift structure | Production records, references | Medium | |||||

| Technical Expertise | Engineering support, design assistance | Staff qualifications, sample projects | High | |||||

| Quality Systems | ISO 9001, industry certifications | Certification documentation | Critical | |||||

| Material Sourcing | Alloy availability, traceability | Material certifications | High | |||||

| Secondary Processes | Plating, anodizing, heat treating | Process certifications, samples | Medium-High |

Supplier Qualification Process

A structured qualification process ensures thorough evaluation:

Initial Screening

- Company Background

- Years in business

- Financial stability

- Industry reputation

- Customer references

- Capability Alignment

- Manufacturing processes

- Material expertise

- Quality certifications

- Capacity availability

Technical Evaluation

Assess technical capabilities through:

- Sample Production

- First article inspection

- Dimensional accuracy

- Material verification

- Surface finish quality

- Process Audit

- Production workflow

- Quality control points

- Testing capabilities

- Documentation systems

Commercial Evaluation

Consider business factors including:

- Cost Structure

- Unit pricing at various volumes

- Tooling and setup costs

- Payment terms

- Volume discount thresholds

- Supply Chain Factors

- Lead times

- Minimum order quantities

- Inventory programs

- Shipping options

A procurement manager at a major electronics manufacturer shared this insight: "We\’ve found that the lowest-cost supplier rarely delivers the best total value. When we factor in quality consistency, technical support, and on-time delivery performance, we often select suppliers with mid-range pricing but superior overall capabilities."

What Are the Cost Factors in Custom Aluminum Set Screw Manufacturing?

The problem of unpredictable pricing and hidden costs in custom fastener procurement creates budgeting challenges and erodes profit margins. Understanding the key cost drivers helps you negotiate fair pricing and identify opportunities for cost optimization.

Custom aluminum set screw pricing is influenced by material selection (alloy type affects cost by 20-50%), production volume (prices typically drop 15-30% at 25,000+ pieces), thread specifications, surface treatments (adding 10-25% to base cost), and secondary operations like inspection and packaging.

Dive-Deeper paragraph: The cost structure for custom aluminum set screws involves multiple variables that interact in complex ways. By understanding these cost drivers and their relative impact, procurement professionals can make informed decisions that balance performance requirements with budget constraints, while also identifying opportunities for cost optimization without compromising quality.

Material Cost Analysis

Raw material represents a significant portion of total cost:

| — | ||||||||

|---|---|---|---|---|---|---|---|---|

| 6061-T6 | 1.0 (baseline) | Moderate | Standard for most applications | |||||

| 2024-T4 | 1.2-1.3 | Moderate-High | Use only where strength required | |||||

| 7075-T6 | 1.5-1.7 | High | Reserve for critical applications | |||||

| 2011-T3 | 1.3-1.4 | Moderate-High | Consider for high-precision needs | |||||

| Recycled Alloys | 0.8-0.9 | Low | Evaluate for non-critical applications |

Volume-Based Pricing Tiers

Production volume significantly impacts unit pricing:

Typical Price Break Structure

- Prototype Quantities (100-500 pcs)

- 3-5x standard unit price

- High setup allocation per piece

- Manual processing components

- Expedited scheduling premium

- Low Volume Production (1,000-5,000 pcs)

- 1.5-2x standard unit price

- Moderate setup cost allocation

- Semi-automated processing

- Standard scheduling

- Medium Volume (5,000-25,000 pcs)

- Standard unit price reference

- Efficient setup cost allocation

- Fully automated processing

- Optimized material utilization

- High Volume (25,000+ pcs)

- 0.7-0.85x standard unit price

- Minimal setup cost per piece

- Continuous production runs

- Volume material discounts

Secondary Operations Cost Impact

Additional processes add incremental costs:

| — | ||||||||

|---|---|---|---|---|---|---|---|---|

| Anodizing | +15-20% | Corrosion resistance, appearance | Application-dependent | |||||

| Tin Plating | +10-15% | Conductivity, lubricity | Critical for electrical | |||||

| Passivation | +5-10% | Corrosion protection | Recommended for most | |||||

| Waxing/Lubrication | +3-5% | Assembly torque control | Valuable for production | |||||

| Custom Packaging | +2-15% | Protection, identification | Depends on handling | |||||

| 100% Inspection | +5-10% | Quality assurance | Critical applications |

Total Cost of Ownership Considerations

Beyond unit price, consider these factors:

- Quality Impact Costs

- Rejection rate differences

- Rework requirements

- Assembly line efficiency

- Warranty implications

- Supply Chain Factors

- Inventory carrying costs

- Lead time implications

- Order management overhead

- Logistics and shipping

A cost engineer at a major fastener manufacturer explained: "Many customers focus exclusively on the unit price, but the smartest buyers understand that quality consistency and supply reliability often deliver greater total cost savings than a few pennies per piece on the purchase price."

How to Optimize the Custom Aluminum Set Screw Design for Manufacturing?

The struggle with designs that are difficult or expensive to manufacture leads to extended lead times, higher costs, and quality issues. Design for Manufacturing (DFM) principles help create custom aluminum set screws that balance performance requirements with manufacturing efficiency.

Optimize aluminum set screw designs by standardizing dimensions where possible, selecting appropriate tolerances (±0.005" for non-critical dimensions), specifying common alloys (6061-T6 for general use), considering thread rolling instead of cutting, and minimizing secondary operations.

Dive-Deeper paragraph: The design optimization process for custom aluminum set screws requires balancing performance requirements with manufacturing considerations. By applying Design for Manufacturing (DFM) principles early in the development process, engineers can create designs that not only meet functional requirements but also minimize production costs, reduce lead times, and ensure consistent quality.

Design Standardization Opportunities

Standardizing certain elements reduces costs while maintaining functionality:

Dimensional Standardization

- Length Increments

- Standard: 1/16" or 1mm increments

- Cost impact: 10-15% savings vs. custom lengths

- Performance impact: Minimal for most applications

- Inventory benefit: Reduced SKU proliferation

- Thread Specifications

- Standard: UNC/UNF or ISO metric threads

- Cost impact: 15-20% savings vs. custom threads

- Performance impact: Minimal with proper selection

- Tooling benefit: Utilizes standard tooling

- Drive Features

- Standard: Common hex sizes (inch or metric)

- Cost impact: 5-10% savings vs. custom drives

- Performance impact: None with proper sizing

- Assembly benefit: Uses standard tools

Tolerance Optimization

Specifying appropriate tolerances balances cost and performance:

| — | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Thread Major Diameter | ±0.001" | ±0.003" | ±0.005" | +30-40% | ||||||

| Thread Pitch Diameter | ±0.0005" | ±0.002" | ±0.003" | +40-50% | ||||||

| Length | ±0.002" | ±0.005" | ±0.010" | +20-25% | ||||||

| Point Geometry | ±0.001" | ±0.003" | ±0.005" | +25-35% | ||||||

| Drive Depth | ±0.002" | ±0.005" | ±0.010" | +15-20% |

Manufacturing Process Selection

Different manufacturing methods offer various trade-offs:

Thread Formation Methods

- Thread Rolling

- Advantages: Stronger threads, better surface finish, faster production

- Limitations: Initial tooling cost, minimum quantities, material constraints

- Cost impact: 15-25% savings in high volume

- Quality benefit: Improved thread strength and consistency

- Thread Cutting

- Advantages: Lower tooling cost, flexibility for small runs, any material

- Limitations: Slower production, interrupted grain structure

- Cost impact: Economic for low volumes

- Quality consideration: Reduced thread strength vs. rolled

- Thread Grinding

- Advantages: Highest precision, works with hardened materials

- Limitations: Slowest process, highest cost

- Cost impact: 30-50% premium

- Application: Precision requirements only

A manufacturing engineer with extensive fastener experience noted: "The most cost-effective designs come from engineering teams that understand manufacturing constraints. When designers specify unnecessarily tight tolerances or non-standard features, they\’re essentially adding cost without adding value."

What Are the Best Practices for Ordering and Managing Custom Aluminum Set Screw Inventory?

The challenge of balancing inventory costs with production needs creates cash flow pressure and risks of stockouts or obsolescence. Strategic inventory management practices help optimize the supply chain for custom aluminum set screws while minimizing total costs.

Optimize inventory management by implementing tiered stocking strategies (high-runners maintained in stock, mid-volume on scheduled releases, low-volume made to order), establishing blanket orders with scheduled releases, and developing vendor-managed inventory programs for critical components.

Dive-Deeper paragraph: Effective inventory management for custom aluminum set screws requires a sophisticated approach that balances multiple competing objectives: minimizing carrying costs, ensuring production availability, maintaining quality consistency, and optimizing cash flow. By implementing strategic inventory programs tailored to usage patterns and criticality, manufacturers can achieve significant improvements in both cost efficiency and operational performance.

Inventory Stratification Strategies

Different usage patterns require different inventory approaches:

| — | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| A-Class (High Volume) | >100,000 pcs | Kanban/JIT | Weekly/Monthly | 2-4 weeks | ||||||

| B-Class (Medium Volume) | 25,000-100,000 pcs | Min/Max | Monthly/Quarterly | 4-6 weeks | ||||||

| C-Class (Low Volume) | 5,000-25,000 pcs | Scheduled Orders | Quarterly/Biannual | 6-8 weeks | ||||||

| D-Class (Sporadic) | <5,000 pcs | Make-to-Order | As needed | Project-specific |

Blanket Order Programs

Structured ordering programs provide multiple benefits:

Blanket Order Structure

- Contract Elements

- Total annual quantity commitment

- Pricing tiers and volume guarantees

- Release schedule flexibility

- Material reservation provisions

- Financial Arrangements

- Payment terms optimization

- Currency hedging if applicable

- Price adjustment mechanisms

- Cancellation terms and liability

- Quality Provisions

- First article approval process

- Ongoing quality requirements

- Lot traceability expectations

- Non-conformance procedures

Vendor-Managed Inventory (VMI) Programs

VMI offers advantages for high-volume, critical components:

- Program Structure

- On-site or near-site inventory

- Consumption-based billing

- Min/max level maintenance

- Automated replenishment

- Technology Integration

- Barcode/RFID tracking

- ERP system integration

- Usage reporting automation

- Forecast sharing mechanisms

- Performance Metrics

- Fill rate monitoring

- Inventory turns optimization

- Carrying cost allocation

- Service level agreements

A supply chain director at a major electronics manufacturer shared this perspective: "We\’ve found that the most successful inventory programs for custom components like aluminum set screws involve true partnerships with suppliers. When we share forecast data and collaborate on inventory strategies, both companies benefit from improved efficiency and reduced total costs."

Contact Us

📧 Email us: [email protected]🌐 Visit: https://primecustomparts.com

Get a free quote, custom tool configuration, and fast delivery worldwide. Every order comes with setup support.

Conclusion

Sourcing custom aluminum set screws requires careful consideration of material options, manufacturer capabilities, cost factors, design optimization, and inventory management strategies to ensure reliable supply of high-quality fasteners that meet exact specifications while maintaining cost efficiency.