How to Source High‑Precision Custom Metal Parts from an ISO‑Certified CNC & Stamping Supplier?

Many buyers cannot find reliable suppliers1 for high-precision custom metal parts2.

Buyers often face issues such as unstable quality, delayed shipments, or poor packaging when purchasing custom CNC or stamping parts1. Selecting an ISO-certified CNC and stamping supplier2 ensures steady quality, rapid communication, and reliable logistics for every project. Reliable partners help buyers meet deadlines and achieve cost savings with consistent part performance.

With thousands of suppliers online, picking the right one is not easy. In this article, I share proven steps for finding a top supplier1. I explain how Prime supports global clients, avoids common sourcing risks2, and delivers peace of mind for buyers.

Why Choose an ISO Certified Metal Stamping & CNC Parts Supplier?

Unreliable quality, communication gaps1, and shipment delays2 hurt any B2B buyer’s business.

ISO-certified metal parts suppliers demonstrate they follow global quality systems1. This means traceable processes, strict inspection, and steady performance. Choosing an ISO-certified supplier2 protects your supply chain from hidden risks.

The ISO Advantage for Custom Metal Parts Sourcing

Before I worked only with ISO-certified suppliers, my clients received parts with incorrect tolerances1 and missing documentation. These mistakes cost time and money. Today, ISO certification2 is my first check for every supplier.

| Factor | ISO Supplier | Non-ISO Supplier |

|---|---|---|

| Quality System1 | Always Present | Often Missing |

| Traceability2 | End-to-End | Limited |

| Quality Documentation | Complete | Sometimes |

| Rework/Complaint Rate | Very Low | Higher |

| Audit Support | Full | Difficult |

An ISO-certified supplier manages each step, from raw material to shipment, with documentation and regular audits. At Prime, we renew our ISO 90011 every year. We welcome buyer audits2, third-party inspections, and supply all test reports. This approach gives global buyers, including North America, Europe, and Australia, confidence to reorder with no surprises.

If your current supplier cannot show ISO credentials, ask for their audit records or look for new partners with proven certification. Picking an ISO-certified stamping parts1 or CNC parts supplier2 helps your team win more contracts and pass any customer audits.

How to Compare Custom CNC Parts Suppliers by Tolerance & Response Time?

Not all suppliers deliver the precision1 and speed2 buyers need.

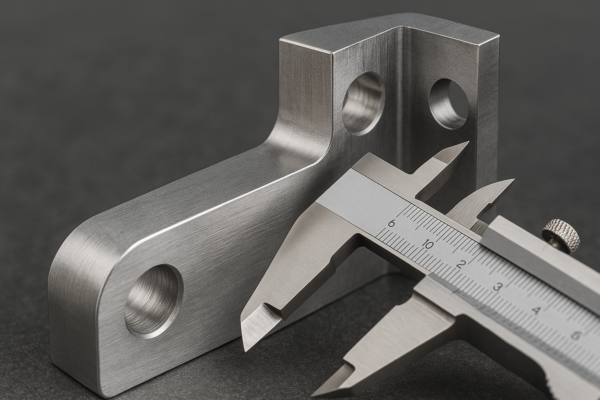

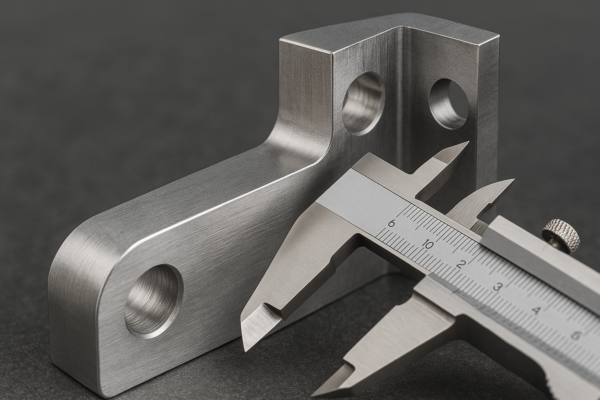

Good CNC parts suppliers provide tight tolerances1, fast quotes2, and detailed sample reports. Comparing suppliers by these standards helps buyers avoid delays and costly errors.

Comparing CNC Suppliers: Tolerance, Speed, and Flexibility

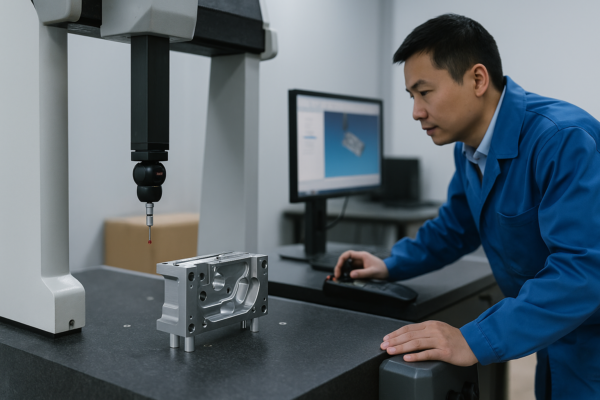

When I help clients select CNC suppliers, I always ask for sample test data and actual measurement reports. Top suppliers use advanced CMM and laser inspection1. They respond to technical questions and send detailed drawings2 quickly.

| Supplier | Max Tolerance1 | Quote Speed | Sample Time | Custom Support | Quality Data2 |

|---|---|---|---|---|---|

| Prime | ±0.01 mm | 24 hours | 5-7 days | Strong | Full Reports |

| Ordinary Factory | ±0.05 mm | 3-7 days | 15 days | Limited | Partial |

My typical checklist includes:

- Can the supplier guarantee ±0.01 mm for every critical part?

- Do they provide CMM and inspection reports1 for every batch?

- Are communication and drawing reviews always fast and detailed?

- Do they support flexible packaging2, labeling, and DFM suggestions?

At Prime, we review every drawing, discuss tolerance limits1, and provide quality reports2 for every delivery. Buyers never need to chase for answers or data.

What Are Progressive Die Stamping Services and Advantages?

Buyers of high-volume metal parts can benefit from progressive die stamping1 but may not understand the value.

Progressive die stamping uses a tool with multiple stations, forming complex parts in a single run. It increases efficiency, lowers per-part cost2, and delivers repeatable quality for large batches.

When Should Buyers Choose Progressive Die Stamping?

Once, a customer needed 200,000 stainless steel clips1. Their old supplier used manual stamping, causing late deliveries and high scrap rates. With Prime’s progressive die stamping2, production speed increased, costs dropped, and every clip met tolerance specs.

| Feature | Progressive Die | Manual Stamping |

|---|---|---|

| Speed | 500-1200/hr | 100/hr |

| Consistency | Excellent | Medium |

| Setup Cost1 | Higher | Lower |

| Per-Part Cost2 | Lower | Higher |

| Quality | Stable | Unpredictable |

Progressive die stamping fits:

- High-volume runs (over 10,000 pieces)1

- Parts with multiple bends, embosses, or holes

- Orders with tight delivery and tolerance needs2

- Projects needing less manual intervention

Prime’s engineering team supports every stage, from die design1 to mass production2. We offer in-house tooling, rapid trial runs, and lifetime die maintenance for every customer.

How Prime Delivers Fast Quotes, Packaging Samples & Export Reliability?

Buyers care about speed, packaging, and reliable export delivery1.

Prime sends formal quotes in less than 24 hours, supplies packaging samples for every new order, and manages every export shipment with strict documentation. Our logistics team supports fast customs clearance2 and insured transport to all regions.

Prime’s 7-Step Sourcing Process

Over the years, I have seen buyers lose profits from slow replies or packaging failures. That is why Prime’s process is clear and responsive:

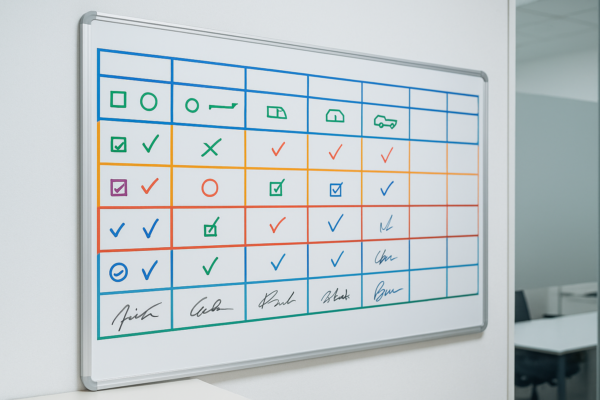

- Buyer sends drawings and specs by email or website.

- Our engineers review and offer cost-saving DFM suggestions1.

- Sales team sends detailed quote within 24 hours.

- We make a packaging sample and send photos or the actual box for approval.

- Production starts after sample signoff.

- Every batch passes full inspection2, including CMM, function, and packaging checks.

- Prime’s export team arranges shipment, provides tracking, and manages delivery.

Every step, from quoting to shipment1, is tracked and reported. We update buyers at each stage and support special requests2 for labeling, pallets, or split delivery.

Best Practices for Communication & Quality Assurance

Clear communication and complete documentation save buyers time and money.

Prime’s bilingual team1 responds to all messages within 12 hours. We use detailed drawings, production photos, and video calls to confirm every requirement. Our quality control reports2 include inspection data, serial numbers, and photos of each shipment.

I have worked with buyers who needed urgent project launches1. With Prime, there is never confusion about delivery times2 or technical details. Our ERP and tracking systems keep orders moving and catch problems before they cause delays.

Prime supports:

- Online and offline customer audits

- Third-party inspections (SGS, TÜV, BV)1

- Confidentiality and intellectual property protection2

- Flexible payment (TT, LC, PayPal)

Every order includes complete documentation: material certificates1, inspection reports2, packaging lists, and photos.

How to Secure Your First Order: Tips for Large Buyers & Traders

Large projects carry more risk, so buyers must minimize surprises.

Start with a trial order1 and confirm packaging with samples. Use digital drawings and signed checklists. Always request recent references2 and track each project stage.

Prime’s account managers provide:

- NDA protection for drawings and contracts1

- Multi-project timeline support

- Dedicated engineers for R\&D and cost-down

-

Real-time shipment tracking and delivery alerts2

Buyers receive a single contact1 for all technical and business questions, so there is no confusion during urgent or multi-country projects2.

Industry Trends: What’s Next in the Custom Metal Parts Market?

Modern buyers want digital support, sustainable solutions, and reliable delivery worldwide.

The best suppliers invest in automation, eco-friendly packaging1, and digital management tools2. Buyers get better prices, faster launches, and stronger partnerships by choosing forward-looking partners.

Prime is upgrading production with:

- Automated stamping and CNC lines1

- Real-time ERP management2

- Digital quality tracking

- Recyclable export packaging

This means more competitive pricing1, less waste, and shorter lead times2 for global buyers.

FAQs

1. What certifications does Prime hold?

Prime is ISO 9001 certified1. We provide inspection reports and traceable documentation for every batch.

2. Can Prime handle urgent orders and small MOQs?

Yes. We offer expedited samples, flexible minimums, and special project support.

3. Which industries use Prime’s parts?

We supply automotive, electronics, construction, machinery, and new energy sectors.

4. Does Prime provide custom packaging with client branding2?

Yes. We offer customized boxes, export labels, barcodes, and pallet services.

5. How does Prime ensure on-time delivery?

We use ERP scheduling and certified logistics partners to meet delivery deadlines.

6. Is Prime open to third-party inspections?

Yes. We welcome SGS, TÜV, BV, or client-appointed QC checks.

7. Can I get engineering help with DFM?

Yes. Prime’s team reviews drawings and offers suggestions to save cost and improve quality.

8. Where does Prime export?

North America, Europe, Australia, Middle East, and other global markets.

9. How fast can I get a quote and sample?

Quotes within 24 hours, samples in 5-7 days for most projects.

10. What payment methods do you accept?

TT, LC, PayPal, and major credit cards.

Conclusion

Work with Prime, an ISO-certified supplier, for high-precision custom metal parts1, fast delivery2, and expert support.

For a free consultation, quotation, and packaging sample, contact us:

Website: https://primecustomparts.com/

Email: [email protected]

Let Prime help your business succeed in every custom metal parts project.

-

Explore this link to understand the significance and applications of high-precision custom metal parts in various industries. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about the importance of fast delivery in manufacturing and how it can enhance efficiency and customer satisfaction. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩