How to strengthen sheet metal parts?

Buyer: I’m working on a new bracket design. The sheet metal part feels a bit too flexible. How can I make it stronger without using thicker material?

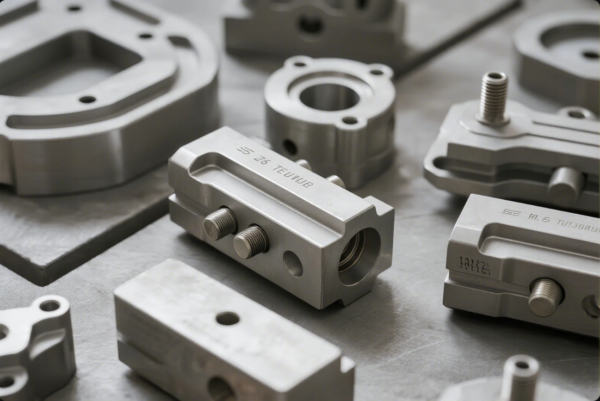

Engineer (Prime): Great question. There are many smart ways to strengthen sheet metal parts—without adding weight or cost. Let’s go over the most effective methods, including bends, ribs, flanges, and materials.

How do you stiffen sheet metal parts?

Buyer: What’s the easiest way to stiffen a thin panel?

Engineer: Here are the most common stiffening methods we use at Prime:

- Bends or folds – Even a simple 90° flange adds major rigidity

- Ribs or embosses – Formed features that stop flex without extra material

- Gussets – Added triangular supports between surfaces

- Flanged holes – Reinforce large cutouts

- Return flanges – Create U- or Z-shapes to resist bending

Summary: You don’t need to make it thicker—shape adds stiffness. A smart bend can replace 30% material.

How can I improve my metal strength?

Buyer: Can I just use a stronger material?

Engineer: Absolutely. Here’s how to boost strength by material selection:

| Material | Tensile Strength (MPa) | Notes |

|---|---|---|

| Mild Steel (1018) | \~400 | Inexpensive and easy to bend |

| Stainless Steel | \~600–800 | Corrosion resistant, stiffer |

| Aluminum (5052) | \~200–280 | Lightweight, softer |

| Titanium (Ti64) | \~900 | Expensive but extremely strong |

At Prime, we often switch from aluminum to stainless if the part needs stiffness without much bending.

Summary: Material upgrades help, but should be balanced against cost and formability.

How do you strengthen steel sheets?

Buyer: What if I’m already using steel but it still flexes?

Engineer: Try one or more of the following:

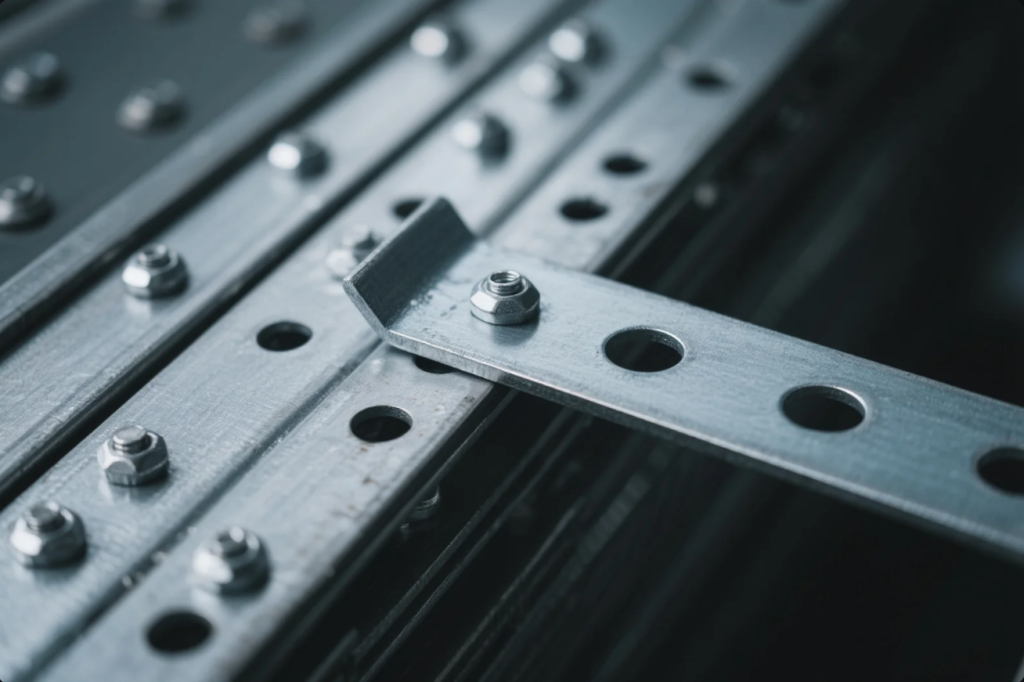

- Weld-on reinforcement channels

- Integrated press-formed ribs

- Double-layered or laminated sheets

- Spot-welded stiffeners behind key zones

- Edge flanges to resist warping

At Prime, we use press brake tooling or stamping dies to form ribs without needing extra parts or welds.

Summary: With steel, you can enhance strength using geometry—no need for thicker sheets unless absolutely necessary.

Does bending sheet metal make it stronger?

Buyer: I’ve heard that bending makes it stronger. Is that true?

Engineer: Yes! Bending increases stiffness dramatically—especially against bending or torsional loads.

Example:

- A flat 2mm sheet deflects under 10kg load

- Add a 20mm flange = 3× less deflection

- U-shapes or C-channels = 5×+ stronger

This is called section modulus—increasing height (bend depth) boosts stiffness.

Summary: Bending is the simplest way to make a metal part more rigid—without extra material or cost.

Frequently Asked Questions (FAQ)

❓ Is thicker sheet metal always stronger?

Engineer: Technically yes—but it’s heavier, harder to bend, and more expensive. Design changes are smarter.

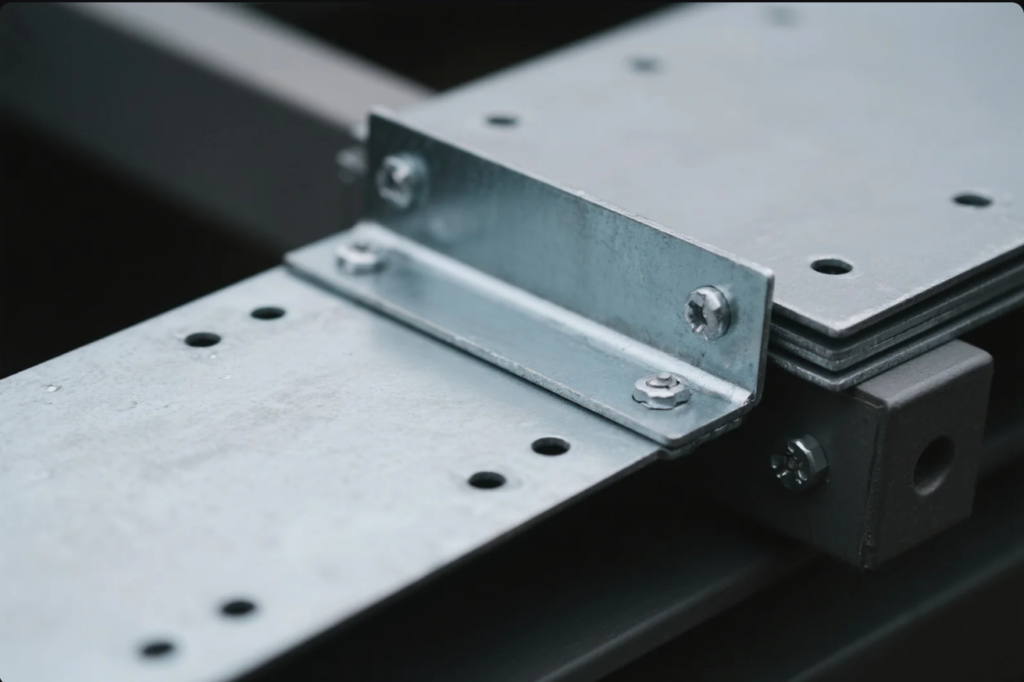

❓ What’s the strongest shape in sheet metal design?

Engineer: A U-channel or a box section adds maximum rigidity with minimum material.

❓ Should I add ribs or just increase thickness?

Engineer: Ribs are cheaper and lighter. Thickness should be a last resort.

❓ Can I add strength after cutting the part?

Engineer: Yes—through secondary bends, spot welds, or reinforcement plates. Prime can help design it.

Conclusion

Buyer: So, how do I strengthen sheet metal parts without just making them thicker?

Engineer: Add bends, ribs, gussets, and smart shapes. And when necessary, consider switching to a stiffer material. At Prime, we help clients strengthen parts through smart design—not higher costs.

Buyer: Perfect. I’ll send over the bracket files for redesign with ribs and flanges.

Engineer: Great—we’ll provide a full DFM review and suggest optimizations that reduce cost while improving performance.

Need stronger parts without extra weight or cost?

Contact Prime for free design analysis, bend optimization, and ISO-certified metal fabrication.

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com