How to tell if something is injection molded?

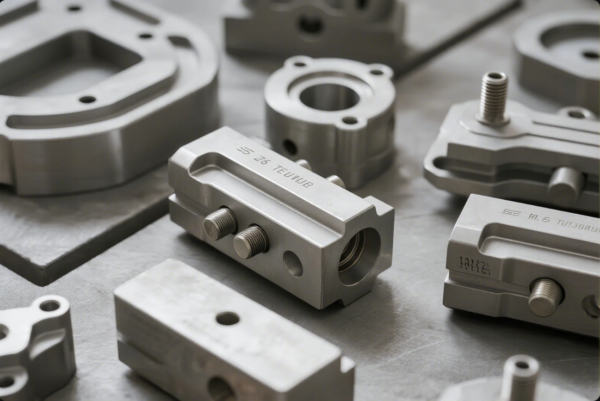

Image: Injection molded part with clearly visible ejector pin marks and parting lines.

Wondering how to tell if something is injection molded?

Injection molded parts have visual and structural clues—such as parting lines, ejector pin marks, and flow patterns—that help you identify the process. Knowing how to tell if something is injection molded can help buyers, engineers, and inspectors make smarter sourcing and quality decisions.

This article will teach you how to tell if a part is injection molded using proven indicators. We’ll also share how to validate the process and why these signs matter in real-world production.

What are the identifying features of injection molding?

To answer “how to tell if something is injection molded,” start by examining the external features.

Most injection molded parts will show consistent texture, defined parting lines, ejector pin circles, and gate vestiges—evidence of mold-based manufacturing.

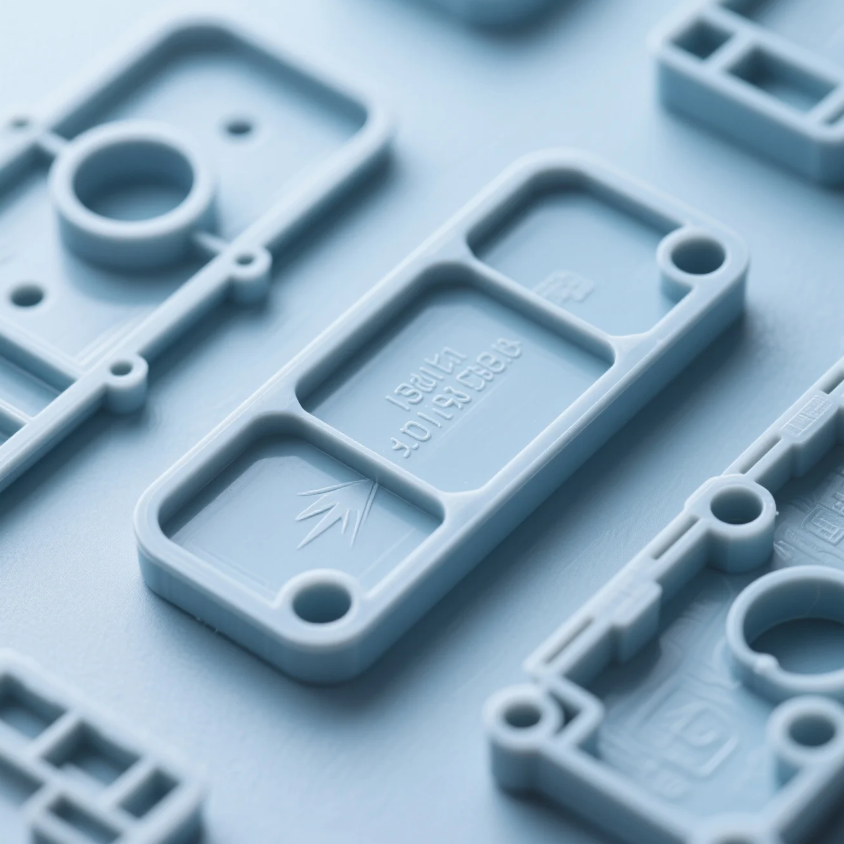

Image: A molded part showing parting lines and gate scars—key signs to tell if something is injection molded.

Visual Clues to Look For

| Feature | Description |

|---|---|

| Parting Line | Seam along the mold’s parting plane |

| Ejector Marks | Small round imprints from ejection pins |

| Gate Remnants | Slight plastic bulge near the injection gate |

| Uniform Wall | Consistent thickness indicates pressure-formed mold |

| Complex Geometry | Single-piece ribs, threads, or undercuts |

At Prime, we help clients review their parts and explain exactly how to tell if something is injection molded. We also improve designs to make these indicators cleaner and more functional.

Discover how Prime enhances molded part design →

What are injection molded signs?

If you’re wondering how to tell if something is injection molded beyond surface appearance, functional details offer more clues.

Injection molded parts often include ribs, draft angles, snap-fit tabs, or insert-molded features—all difficult to achieve through other processes.

Image: Molded plastic housing with functional ribs and clips, confirming injection-based production.

Engineering Signs of Molding

- Draft angles ensure parts eject easily

- Support ribs add strength without bulk

- Living hinges or flex-tabs molded directly into the part

- Insert integration combines metal and plastic at once

- Embossed text created directly during the molding process

All these details can help you determine how to tell if something is injection molded—especially in consumer electronics, automotive, and industrial enclosures.

Explore Prime’s integrated molding solutions →

What does injection molding look like?

If you’re asking “how to tell if something is injection molded” based on visual patterns, surface finish is the next thing to check.

Injection molded parts usually have smooth, uniform surfaces, subtle seam lines, and occasional flow or weld marks.

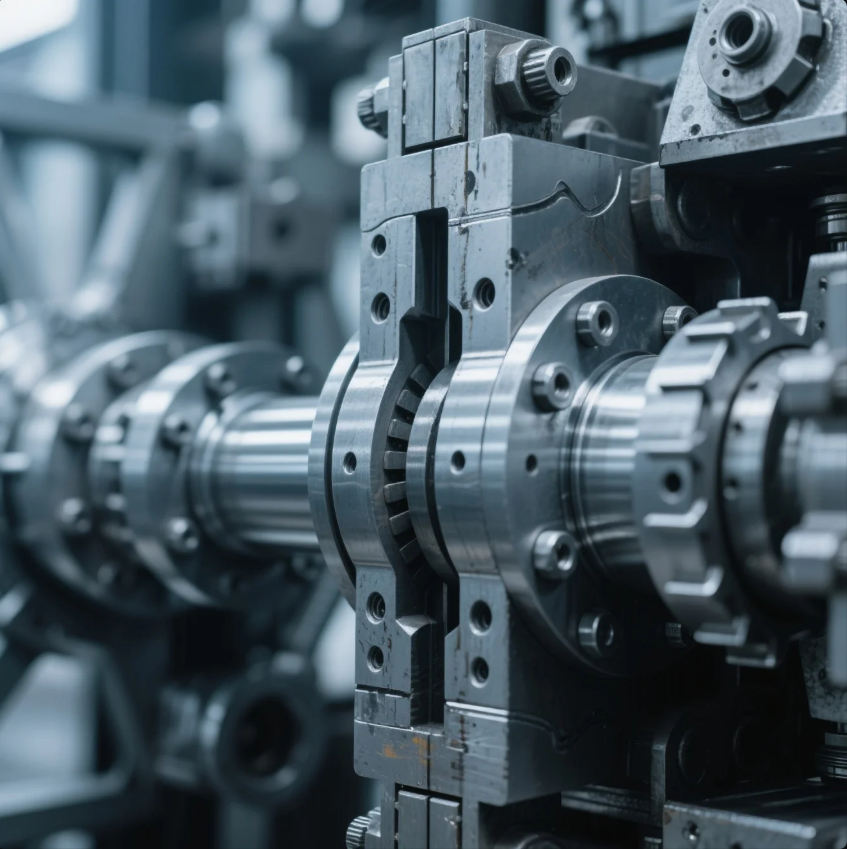

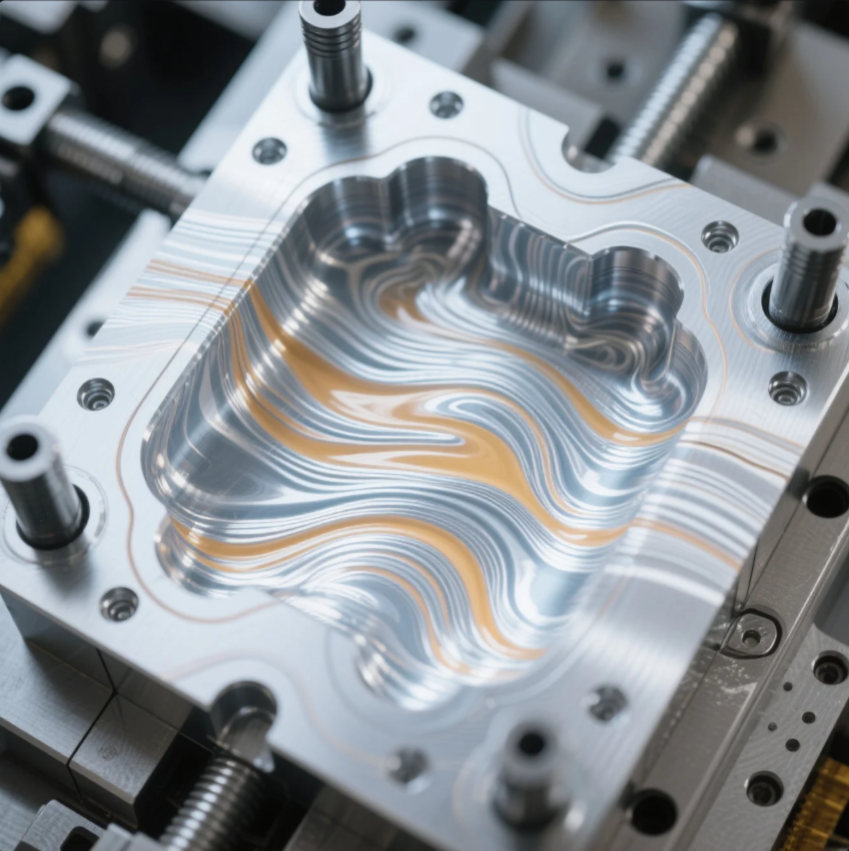

Image: Molded surface showing flow lines, weld lines, and gate vestiges—visual signs of injection molding.

Surface Traits That Reveal Molding

| Observation | What It Suggests |

|---|---|

| Glossy or matte | Depends on mold texture or tool finish |

| Flow lines | Visible streaks from molten plastic movement |

| Weld lines | Lines where two plastic flows meet inside the mold |

| Molded-in marks | Batch numbers, logos, or symbols built into tooling |

At Prime, we adjust mold temperature and injection speed to reduce visible defects. Our team also helps clients learn how to tell if something is injection molded by reviewing physical samples side by side.

Compare Prime’s surface options and textures →

How to validate an injection molding process?

Once you know how to tell if something is injection molded, you also need to verify it was molded correctly.

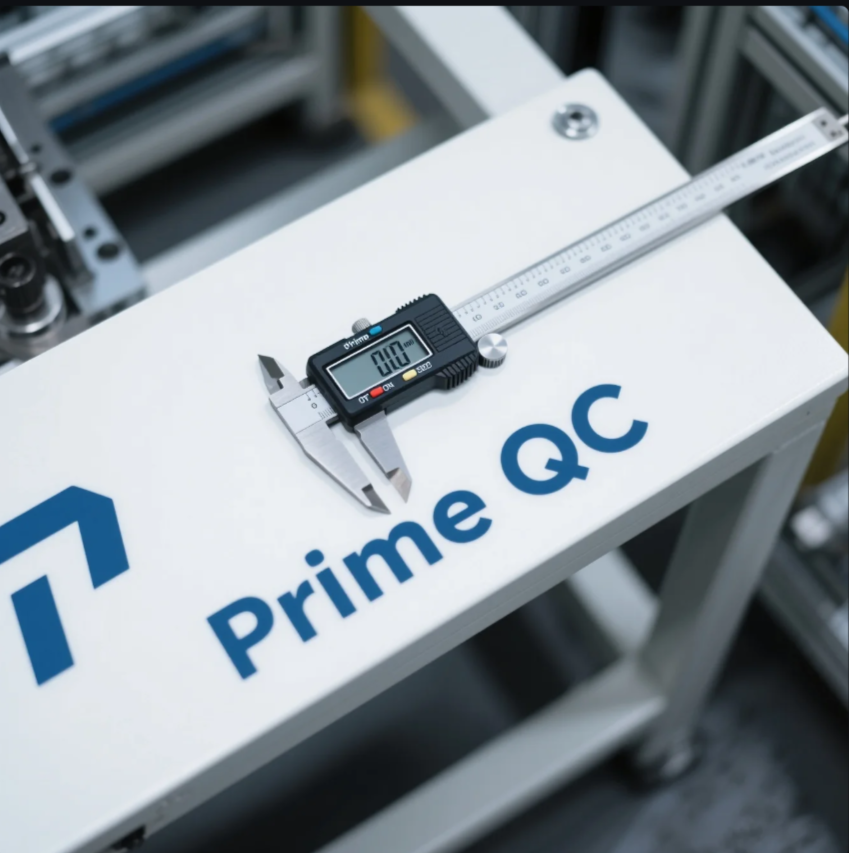

True validation includes dimensional inspection, process parameter logs, and mold maintenance tracking. It’s how you confirm consistent quality and repeatability.

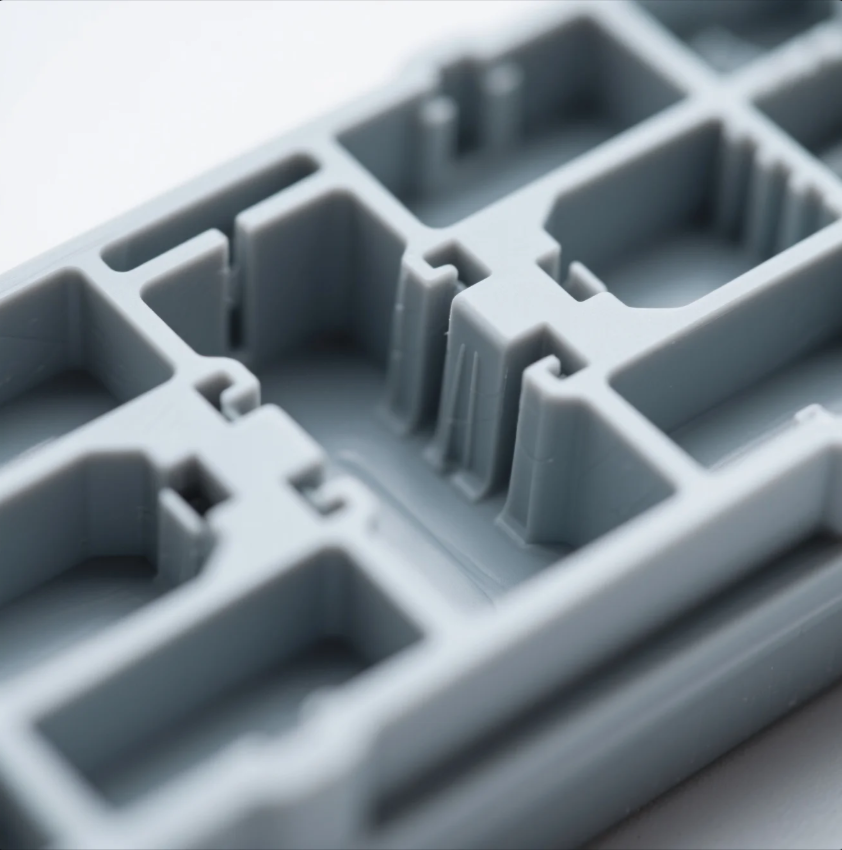

Image: Prime inspector using calibrated tools to verify dimensions of a molded part.

Injection Molding Validation Checklist

| Validation Task | Why It Matters |

|---|---|

| First Article Inspection | Confirms part matches drawings and models |

| Tolerance Check | Verifies dimensions using calipers or CMM |

| Material Certification | Confirms resin grade and compliance (e.g., RoHS) |

| Injection Parameters Log | Records temperature, pressure, time, and speed |

| Tool Wear Review | Ensures consistent output from the mold |

At Prime, we supply full PPAP and quality documentation with every mold order. If you’re unsure how to tell if something is injection molded correctly, we’re here to help with real reports, not guesswork.

Request a sample validation file →

Conclusion

Still asking how to tell if something is injection molded? Just look closely—parting lines, ejector marks, and surface uniformity tell the story. Validation tools help confirm it with certainty.

Want help identifying or verifying molded parts?

Contact Prime today at https://primecustomparts.com or https://primecustomparts.com. We’ll help you understand how to tell if something is injection molded—and how to improve it.

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com