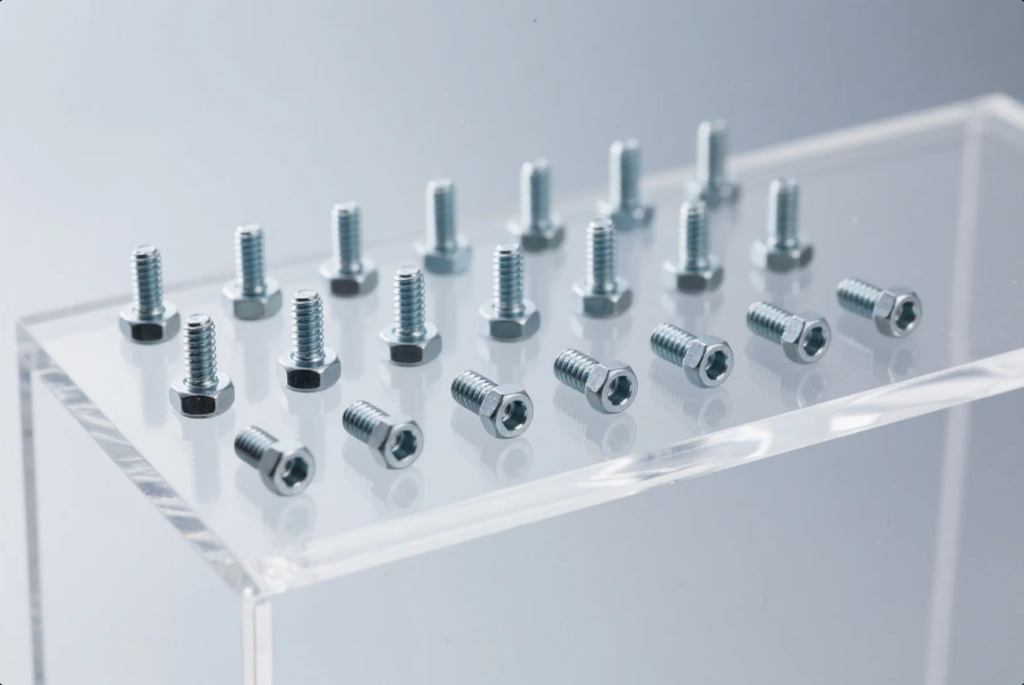

How to Troubleshoot Common Problems with Aluminum Set Screws?

The frustration of fastener failures can compromise product integrity, create safety hazards, and lead to costly repairs. Aluminum set screws present unique challenges due to their material properties, but with proper troubleshooting techniques, most common problems can be quickly identified and resolved.

Common aluminum set screw problems include thread galling, insufficient holding power, corrosion issues, and drive feature damage, which can be resolved through proper material selection, correct installation torque (typically 30-60% of steel equivalents), compatible surface treatments, and appropriate point style selection.

Before replacing problematic aluminum set screws with steel alternatives, consider these troubleshooting approaches that might solve your issues while maintaining the advantages of aluminum fasteners.

How to Prevent Thread Galling in Aluminum Set Screws?

The pain of galled threads that seize and become impossible to remove creates maintenance nightmares and component damage. Thread galling in aluminum set screws occurs when friction causes material transfer between mating surfaces, effectively welding them together.

Prevent thread galling in aluminum set screws by using compatible surface treatments (tin plating, anodizing), applying appropriate thread lubricants (wax, anti-seize compounds), controlling installation torque (30-60% of steel equivalents), and ensuring proper thread class fit (Class 2A/2B preferred).

Dive-Deeper paragraph: Thread galling is particularly problematic with aluminum fasteners due to the material\’s relatively soft nature and tendency to transfer under pressure and friction. Understanding the mechanisms behind galling and implementing preventive measures requires a multifaceted approach that addresses material properties, surface conditions, installation practices, and environmental factors.

Understanding the Galling Mechanism

Thread galling occurs through a specific sequence of events:

| — | ||||||||

|---|---|---|---|---|---|---|---|---|

| Initial Contact | Surface asperity interaction | Surface roughness, contamination | None visible | |||||

| Adhesion | Micro-welding between peaks | Pressure, friction, material compatibility | Slight binding | |||||

| Material Transfer | Shearing and transfer of material | Continued rotation, increasing friction | Visible damage, increased torque | |||||

| Seizure | Complete binding of threads | Accumulated material transfer | Impossible rotation, visible damage |

Surface Treatment Solutions

Different surface treatments offer varying degrees of galling protection:

Anodizing

- Type II Anodizing (Sulfuric Acid)

- Creates hard oxide layer

- Excellent galling resistance

- Good corrosion protection

- Slight dimensional change

- Type III Anodizing (Hard Anodizing)

- Superior hardness

- Maximum galling resistance

- Excellent wear resistance

- Greater dimensional change

- Considerations for Anodized Threads

- Thread dimensions must account for coating thickness

- Color options available for identification

- May affect electrical conductivity

- Superior for frequent adjustment applications

Plating Options

- Tin Plating

- Excellent lubricity

- Good electrical conductivity

- Moderate galling resistance

- Ideal for electrical applications

- PTFE Coating

- Superior lubricity

- Excellent chemical resistance

- Non-conductive

- Limited temperature range

Lubrication Strategies

Proper lubrication significantly reduces galling risk:

| — | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Wax | Good | -20°F to 180°F | Poor | General purpose | ||||||

| Molybdenum Disulfide | Excellent | -300°F to 750°F | Poor | High temperature | ||||||

| Anti-Seize Compound | Excellent | -65°F to 2400°F | Varies by type | Frequent disassembly | ||||||

| Graphite | Very Good | -300°F to 1000°F | Excellent | Electrical applications | ||||||

| PTFE-Based | Very Good | -400°F to 500°F | Poor | Chemical exposure |

Installation Best Practices

Proper installation techniques prevent galling:

- Torque Control

- Use calibrated torque tools

- Apply 30-60% of steel equivalent torque

- Consider torque-tension relationship

- Account for lubrication effects

- Thread Engagement

- Ensure minimum 1.5x diameter engagement

- Avoid cross-threading

- Clean threads before assembly

- Use proper alignment techniques

A materials engineer I consulted explained: "The key to preventing galling is understanding that it\’s a system problem, not just a material issue. You need to consider the fastener material, mating material, surface treatments, lubrication, installation method, and service environment as an integrated system."

What Causes Insufficient Holding Power in Aluminum Set Screws?

The challenge of fasteners that loosen or slip under load compromises assembly integrity and creates safety hazards. Aluminum set screws may provide inadequate holding power due to material properties, improper point style selection, or installation errors.

Improve aluminum set screw holding power by selecting appropriate alloys (7075-T6 for maximum strength), choosing effective point styles (cup point for maximum grip, dog point for positive location), ensuring adequate thread engagement (minimum 1.5x diameter), and applying proper installation torque.

Dive-Deeper paragraph: The holding power of aluminum set screws is influenced by multiple interrelated factors that must be optimized for specific application requirements. When analyzing holding power issues, engineers must consider not only the fastener itself but also the mating component properties, loading conditions, and environmental factors that affect joint integrity over time.

Alloy Selection for Maximum Strength

Different aluminum alloys offer varying strength profiles:

| — | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 2024-T4 | 470 | 285 | 120 | Very Good | ||||||

| 6061-T6 | 310 | 207 | 95 | Good | ||||||

| 7075-T6 | 570 | 350 | 150 | Excellent | ||||||

| 2011-T3 | 380 | 230 | 100 | Good | ||||||

| 5052-H32 | 230 | 140 | 60 | Fair |

Point Style Optimization

The point style dramatically affects holding capability:

Cup Point Performance

- Holding Mechanism

- Creates indentation in shaft

- Provides maximum holding power

- Concentrates pressure at contact point

- Resists both rotational and axial movement

- Application Considerations

- May damage shaft surface

- Difficult to adjust position after setting

- Excellent for permanent installations

- Not recommended for frequent adjustment

- Material Compatibility

- Excellent for harder mating materials

- May excessively damage soft materials

- Consider relative hardness ratio

- Hardened cup points available for increased performance

Dog Point Performance

- Holding Mechanism

- Positive location in pre-drilled hole

- Excellent alignment capability

- Maximum resistance to rotation

- Good axial holding power

- Application Considerations

- Requires precisely located hole

- Excellent for repeatable positioning

- Good for frequent disassembly

- Minimal damage to mating component

Thread Engagement Factors

Proper thread engagement is critical for holding power:

- Minimum Engagement Guidelines

- Standard recommendation: 1.5x nominal diameter

- For aluminum threads: 2x nominal diameter

- For critical applications: 2.5x nominal diameter

- For vibration environments: 3x nominal diameter

- Thread Class Considerations

- Class 2 fit (standard): Good balance of assembly ease and holding power

- Class 3 fit (precision): Maximum holding power, more difficult assembly

- Class 1 fit (loose): Easy assembly, reduced holding power

A mechanical engineer specializing in fastener applications noted: "Many holding power issues with aluminum set screws stem from treating them like steel fasteners. Aluminum requires different design considerations—more thread engagement, appropriate point styles for the application, and careful torque control during installation."

How to Address Corrosion Issues with Aluminum Set Screws?

The frustration of corroded fasteners that become difficult to remove and compromise joint integrity creates maintenance challenges and potential safety hazards. Aluminum set screws are susceptible to specific corrosion mechanisms that require targeted prevention strategies.

Prevent corrosion in aluminum set screws by selecting appropriate alloys (6061 for general corrosion resistance), applying protective treatments (anodizing, chromate conversion), avoiding galvanic couples with dissimilar metals, and using protective sealants in wet environments.

Dive-Deeper paragraph: Corrosion of aluminum set screws involves several distinct mechanisms that must be understood to implement effective prevention strategies. While aluminum naturally forms a protective oxide layer, this passive film can be compromised under specific conditions, leading to various forms of corrosion that affect both appearance and structural integrity.

Common Corrosion Mechanisms

Different corrosion types affect aluminum set screws:

| — | ||||||||

|---|---|---|---|---|---|---|---|---|

| Galvanic Corrosion | Electrochemical reaction between dissimilar metals | White powder, pitting near contact with other metals | Dissimilar metal contact, electrolyte presence | |||||

| Pitting Corrosion | Localized breakdown of passive layer | Small holes or pits in surface | Chlorides, stagnant moisture, surface defects | |||||

| Crevice Corrosion | Oxygen concentration cell in tight spaces | Corrosion in threads and under heads | Trapped moisture, inadequate sealing | |||||

| Stress Corrosion Cracking | Combined effect of tensile stress and corrosive environment | Cracking without significant deformation | High stress, specific corrosive agents | |||||

| Intergranular Corrosion | Attack along grain boundaries | Loss of strength without visible surface damage | Improper heat treatment, sensitized structure |

Protective Surface Treatments

Surface treatments provide varying levels of protection:

Anodizing Options

- Type I Anodizing (Chromic Acid)

- Thin, flexible coating

- Good corrosion resistance

- Minimal dimensional change

- Excellent for threaded components

- Type II Anodizing (Sulfuric Acid)

- Medium thickness coating

- Very good corrosion resistance

- Accepts dyes for color coding

- Standard for most applications

- Type III Anodizing (Hard Anodizing)

- Thick, hard coating

- Excellent corrosion and wear resistance

- Significant dimensional change

- Best for severe environments

Chemical Conversion Coatings

- Chromate Conversion

- Excellent corrosion protection

- Minimal dimensional change

- Good base for paint adhesion

- RoHS compliance issues with hexavalent chromium

- Trivalent Chromium

- Good corrosion protection

- Environmentally compliant

- Slightly less effective than hexavalent

- Better for regulatory compliance

- Non-chromium Alternatives

- Varying performance levels

- Environmentally friendly

- Emerging technology

- Application-specific effectiveness

Galvanic Isolation Strategies

Preventing galvanic corrosion requires specific approaches:

- Isolation Techniques

- Non-conductive washers

- Dielectric compounds

- Protective sleeves

- Conformal coatings

- Material Compatibility

- Galvanic compatibility chart usage

- Selection of compatible fastener materials

- Consideration of environmental factors

- Surface area ratio management

A corrosion specialist with extensive experience in marine applications shared this insight: "The most effective approach to preventing corrosion in aluminum fasteners is a systems approach. You need to consider the entire assembly—the fastener, the mating components, the environment, and the protective measures—as an integrated system rather than focusing on the fastener in isolation."

How to Prevent Drive Feature Damage During Installation and Removal?

The problem of damaged drive features makes fasteners difficult or impossible to remove, leading to costly repairs and maintenance delays. Aluminum set screws are particularly susceptible to drive damage due to their relatively soft material properties.

Prevent drive damage in aluminum set screws by using high-quality installation tools (precision hex keys for socket drives), applying axial pressure during turning, selecting appropriate drive types for the application (hex socket for higher torque), and using proper torque control methods.

Dive-Deeper paragraph: Drive feature damage in aluminum set screws represents one of the most common and frustrating issues encountered in fastener applications. The relatively soft nature of aluminum makes it particularly susceptible to deformation, stripping, and rounding during installation and removal. Understanding the mechanics of drive damage and implementing preventive measures requires attention to tool selection, installation technique, and fastener design considerations.

Drive Type Selection Considerations

Different drive types offer varying resistance to damage:

| — | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Hex Socket | Excellent | Very Good | Excellent | High torque, limited access | ||||||

| Slotted | Poor | Poor | Excellent | Low torque, visible applications | ||||||

| Phillips | Fair | Fair | Excellent | Low-medium torque, consumer products | ||||||

| Torx/Star | Excellent | Excellent | Good | High torque, frequent removal | ||||||

| Square/Robertson | Very Good | Very Good | Fair | Medium-high torque, wood applications | ||||||

| Combination | Good | Good | Fair | Multiple tool compatibility |

Tool Quality and Selection

Proper tools significantly reduce drive damage risk:

Hex Key (Allen Wrench) Considerations

- Material Quality

- Tool steel (good)

- Chrome vanadium steel (better)

- S2 tool steel (best)

- Ball-end for angular access (convenience vs. strength trade-off)

- Dimensional Accuracy

- Precision ground vs. stamped

- Tolerance class considerations

- Wear monitoring and replacement

- Size-specific tools vs. multi-tools

- Tool Condition Factors

- Wear inspection

- Deformation monitoring

- Corrosion prevention

- Proper storage

Installation Technique Best Practices

Proper technique prevents most drive damage:

- Axial Pressure Application

- Maintain firm pressure along fastener axis

- Ensure full tool engagement

- Use two hands when possible

- Consider tool handle design for leverage

- Rotation Control

- Smooth, controlled movement

- Avoid jerky or sudden force

- Listen for binding or galling

- Stop if resistance increases unexpectedly

- Torque Application

- Use calibrated torque tools when possible

- Develop feel for appropriate torque

- Consider torque-limiting tools

- Account for lubrication effects on torque

A tool design engineer I consulted explained: "The quality difference between economy and professional-grade hex keys is substantial. Premium tools maintain tighter tolerances, use superior materials, and have better edge definition—all factors that significantly reduce the risk of damaging aluminum fastener drives."

What Are the Best Practices for Aluminum Set Screw Installation?

The challenge of inconsistent installation leads to variable performance, premature failures, and maintenance issues. Proper installation techniques for aluminum set screws differ significantly from those used with steel fasteners due to material property differences.

Install aluminum set screws correctly by cleaning and inspecting threads before assembly, applying appropriate lubricant, using calibrated torque tools (30-60% of steel equivalents), ensuring proper alignment, and following manufacturer\’s specific torque recommendations when available.

Dive-Deeper paragraph: The installation process for aluminum set screws requires attention to detail and an understanding of how aluminum\’s unique properties affect fastener behavior. Proper installation techniques not only prevent immediate problems like galling and drive damage but also ensure long-term performance and reliability under service conditions. A systematic approach to installation addresses preparation, technique, torque control, and verification.

Pre-Installation Preparation

Proper preparation prevents many installation problems:

Thread Inspection and Cleaning

- Visual Inspection

- Check for thread damage

- Inspect point condition

- Verify drive feature integrity

- Confirm correct fastener specification

- Thread Cleaning

- Remove debris and contamination

- Use appropriate solvents

- Consider compressed air cleaning

- Inspect female threads in mating component

- Lubrication Application

- Select appropriate lubricant

- Apply thin, even coating

- Ensure coverage of all threads

- Wipe excess from point and drive

Torque Control Methods

Proper torque is critical for aluminum fasteners:

| — | ||||||||

|---|---|---|---|---|---|---|---|---|

| Calibrated Torque Wrench | Precise, repeatable | Equipment cost, calibration requirements | Critical applications | |||||

| Torque-Limiting Tools | Prevents overtightening | Limited adjustment range | Production environments | |||||

| Feel Method (Experienced Installer) | No special tools, fast | Subjective, requires experience | Non-critical applications | |||||

| Turn-of-Nut Method | Simple, no special tools | Less precise | Structural applications | |||||

| Computerized Torque-Angle Systems | Highest precision, data logging | Highest cost, complexity | Aerospace, medical |

Torque Guidelines for Aluminum Set Screws

Appropriate torque values vary by size and application:

General Torque Recommendations

- Percentage of Steel Equivalent

- General rule: 30-60% of steel torque

- Fine threads: Use lower end of range

- Coarse threads: Use higher end of range

- Critical applications: Consult engineering

- Size-Specific Guidelines

-

4-40: 2-3 in-lbs

-

6-32: 3-4 in-lbs

-

8-32: 4-5 in-lbs

-

10-32: 5-7 in-lbs

- 1/4-20: 8-10 in-lbs

- 5/16-18: 15-18 in-lbs

- 3/8-16: 20-25 in-lbs

-

- Application Adjustments

- Electrical connections: Use upper range

- Frequent adjustment: Use lower range

- Vibration environment: Use thread locker

- Thermal cycling: Consider expansion effects

Verification Methods

Confirming proper installation ensures reliability:

- Visual Verification

- Thread engagement check

- Point contact verification

- Drive condition inspection

- Alignment confirmation

- Functional Testing

- Component movement check

- Electrical continuity testing (if applicable)

- Load testing where appropriate

- Vibration resistance verification

A fastener installation specialist with 25 years of experience noted: "The biggest mistake I see with aluminum set screws is treating them like steel. They require a more delicate touch, proper lubrication, and significantly lower torque. When installed correctly, they perform exceptionally well in the right applications."

How to Select the Right Aluminum Set Screw for Specific Environmental Conditions?

The frustration of premature fastener failure due to environmental factors leads to costly maintenance and potential safety hazards. Different environments require specific aluminum set screw properties and treatments to ensure reliable long-term performance.

Select appropriate aluminum set screws for specific environments by choosing suitable alloys (6061-T6 for corrosive conditions, 7075-T6 for high-stress applications), specifying proper surface treatments (anodizing for outdoor use, tin plating for electrical applications), and considering temperature limitations (-65°F to 350°F typical range).

Dive-Deeper paragraph: Environmental conditions significantly impact the performance and longevity of aluminum set screws. The selection process must consider not only the immediate functional requirements but also the long-term effects of temperature, humidity, chemical exposure, UV radiation, and other environmental factors. A systematic approach to environmental selection ensures that fasteners will maintain their integrity throughout the expected service life.

Temperature Considerations

Temperature extremes and cycling affect performance:

| — | ||||||||

|---|---|---|---|---|---|---|---|---|

| Cryogenic (-320°F to -65°F) | 5052, 6061 | None or Type II anodize | Embrittlement risk, thermal contraction | |||||

| Standard (-65°F to 200°F) | All common alloys | All standard treatments | Normal operating range for most applications | |||||

| Elevated (200°F to 350°F) | 2024, 7075 | Type III anodize | Strength reduction at upper range | |||||

| High Temperature (>350°F) | Not recommended | Not applicable | Consider alternative materials |

Corrosive Environment Selection

Different corrosive environments require specific approaches:

Marine/Saltwater Exposure

- Alloy Selection

- 5052: Excellent saltwater resistance

- 6061: Very good with proper treatment

- 6063: Good with proper treatment

- Avoid 2000 and 7000 series if possible

- Surface Treatment Requirements

- Type II or III anodizing

- Marine-grade sealants

- Sacrificial anode consideration

- Regular inspection protocol

- Design Considerations

- Avoid water traps

- Minimize crevices

- Consider isolation from dissimilar metals

- Plan for regular maintenance

Industrial/Chemical Exposure

- Chemical Compatibility Analysis

- Specific chemical resistance charts

- pH tolerance range

- Concentration effects

- Temperature influence on reactivity

- Protective Strategies

- Chemical-specific coatings

- Isolation techniques

- Scheduled replacement programs

- Monitoring protocols

UV and Weather Exposure

Outdoor applications face specific challenges:

- UV Effects on Aluminum

- Minimal direct material impact

- Potential coating degradation

- Aesthetic changes over time

- Secondary effects on sealants

- Weather Resistance Strategies

- Type II or III anodizing

- UV-resistant sealants

- Water drainage considerations

- Thermal cycling accommodation

Electrical Environment Considerations

Electrical applications have unique requirements:

- Conductivity Requirements

- Tin plating for enhanced conductivity

- Contact resistance considerations

- Thermal cycling effects

- Oxidation prevention

- EMI/RFI Environments

- Grounding considerations

- Surface conductivity maintenance

- Corrosion prevention for contact surfaces

- Regular inspection for oxidation

An environmental testing engineer shared this perspective: "The key to successful fastener selection for challenging environments is understanding the specific stressors present and how they interact with the fastener material and treatments. It\’s rarely just one factor—it\’s the combination of temperature, humidity, chemical exposure, and mechanical stress that determines long-term performance."

Contact Us

📧 Email us: [email protected]🌐 Visit: https://primecustomparts.com

Get a free quote, custom tool configuration, and fast delivery worldwide. Every order comes with setup support.

Conclusion

Troubleshooting aluminum set screw problems requires understanding their unique properties and implementing appropriate solutions for thread galling, holding power, corrosion, drive damage, and installation challenges, while selecting the right fastener for specific environmental conditions.