Metal Casting vs. Other Manufacturing Processes: Which is Better for Your Needs?

Choosing the right manufacturing process can save costs, improve quality, and speed up production—but picking the wrong one leads to wasted budgets, failed parts, and delays. With three decades in metal fabrication, we've seen clients lose thousands by using CNC machining when casting was the smarter choice (and vice versa!).

Metal casting excels in complex, high-volume production of strong, net-shaped parts, while CNC machining, forging, and sheet metal fabrication are better for precision, small batches, or high-strength requirements—the optimal process depends on design complexity, material, quantity, and performance needs.

Still unsure which method fits your project? Below, we break down the key differences, costs, and best-use cases for all major manufacturing technologies.

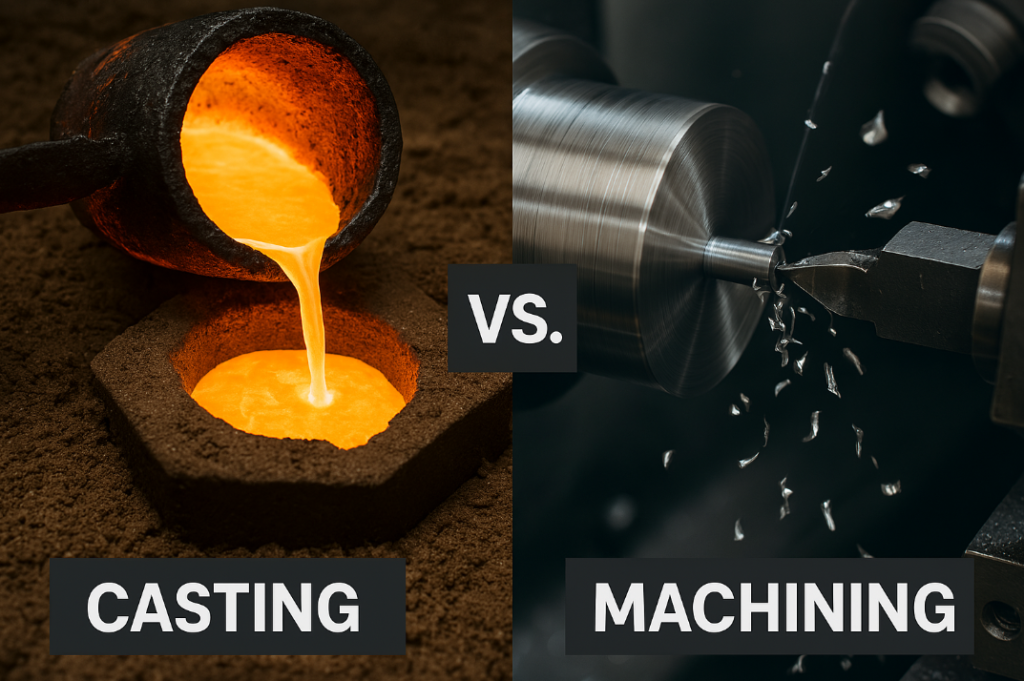

1. How Does Metal Casting Compare to CNC Machining?

Casting creates shapes; machining refines them.

Key differences:

✔ Casting: Better for hollow/3D shapes, internal features, high-volume production

✔ CNC Machining: Superior for tight tolerances (±0.025mm), small batches, surface finish

We helped an aerospace client reduce part cost by 60% by switching from full CNC to cast + finish machining.

Casting vs. Machining: Decision Guide

| Factor | Metal Casting Wins When... | CNC Machining Wins When... |

|---|---|---|

| Part Complexity | Internal channels, thin walls needed | Simple geometries, sharp edges |

| Volume | 500+ parts (lower per-unit cost) | Prototypes or <100 units |

| Lead Time | 2-4 weeks for tooling, fast bulk production | 1-2 weeks (no molds needed) |

| Material Waste | Near-net shape (5-10% waste) | High waste (up to 80% for billets) |

2. When Should You Choose Forging Over Casting?

Forged parts last longer under stress, but cost more.

Critical considerations:

- Strength: Forgings have continuous grain flow (25% stronger)

- Cost: Castings are cheaper for complex shapes

- Applications: Forged for crankshafts, gears; cast for housings, manifolds

A mining company switched from cast to forged loader brackets and saw 3X longer lifespan.

3. Is Sheet Metal Fabrication or Casting More Cost-Effective?

Sheet metal wins for hollow, lightweight enclosures.

Sheet metal advantages:

✔ Faster for flat/simple shapes (no pattern needed)

✔ Lower tooling costs (stamping vs. sand casting)

✔ Better for low-weight designs (e.g., electronic housings)

However, cast aluminum handles vibration better than sheet metal in engine mounts.

4. How Does 3D Printing Disrupt Traditional Casting?

3D printing excels in prototypes, no tooling required.

| Metal 3D printing vs. casting: | Factor | 3D Printing | Casting |

|---|---|---|---|

| Cost Per Part | High (for metals) | Low (volume discounts) | |

| Material Options | Limited alloys | 1000+ alloy choices | |

| Surface Finish | Rough (requires polishing) | Smoother (investment casting) |

We combine both—3D-printed sand molds cut casting lead times by 70%.

5. Which Process Offers the Best Material Properties?

Different methods perform better with specific metals.

| Performance comparison: | Material | Best Process | Why? |

|---|---|---|---|

| Steel | Forging (high strength) | Eliminates casting porosity | |

| Aluminum | Casting (lightweight) | Complex shapes, good corrosion resistance | |

| Titanium | Investment Casting (aerospace) | Minimizes machining costs |

6. How Do Costs Compare Across All Methods?

Breakeven points decide the most economical choice.

Cost-saving breakdown:

✔ <100 parts: CNC machining or 3D printing

✔ 100–1,000 parts: Die casting or sand casting

✔ 10,000+ parts: High-pressure die casting

A client saved $8.50/part by switching from CNC to casting at 2,000-unit orders.

7. What About Lead Times and Scalability?

Some processes speed up production; others slow it down.

Key speed factors:

✔ Casting: Slow first batch (tooling required), then fast mass production

✔ Machining: Quick start (no molds), but slower per-part output

✔ Forging: Moderate setup, limited design changes later

Conclusion

No single process is "best"—only the best for your specific needs. Casting dominates for complex, high-volume metal parts, while CNC suits precision prototypes, forging fits high-stress applications, and sheet metal works for lightweight panels. At Prime, we help clients optimize manufacturing strategies daily—let’s analyze your project to recommend the fastest, strongest, and most cost-effective solution. Need expert guidance? Contact us today for a free process comparison.