Plastic vs. Metal Parts: When to Choose Plastic?

Many engineers and buyers struggle to decide between plastic and metal parts. Making the wrong choice can result in product failure or excess cost.

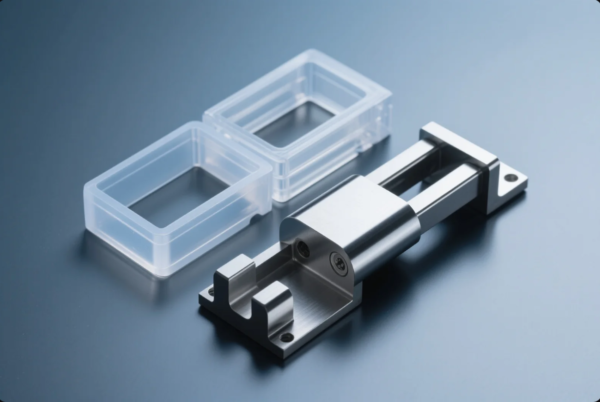

Plastic and metal parts each offer unique advantages. The best choice depends on your project’s application, strength requirements, cost targets, and environmental demands. In this guide, I compare the performance, cost, and practical use of both materials.

Selecting the right material helps you reduce costs, speed up production, and ensure stable quality. This article will show you when plastic is the smarter solution—and when you should stick with metal.

Where will you prefer plastics over metals?

Buyers often wonder whether using plastic will hurt product durability. They also worry that switching to plastic may affect the company’s reputation for quality.

You should choose plastics over metals when your application requires lighter weight, better corrosion resistance, or more design freedom. Plastics are ideal for electrical insulation, chemical resistance, and complex shapes.

Plastics provide reliable performance in many situations, such as electrical insulation for terminal blocks, wire connectors, and cable glands, lightweight parts for automotive, aerospace, or drone manufacturing, and corrosion-resistant components for pumps, valves, and lab equipment. When you need complex shapes, precision molding makes custom plastic parts easy, while high-volume consumer goods like toys and home electronics favor plastics for cost and speed.

In my experience, a U.S. client who switched electronics housings from metal to plastic saw shipping costs drop 30%, while rust complaints disappeared. For more on plastics in manufacturing, see Plastics Today, Plastics Europe, or the MatWeb plastics database.

Is it better to use metal or plastic?

Some customers assume metals always outperform plastics. However, each has distinct strengths.

Metal parts offer superior strength, thermal performance, and wear resistance. Plastics provide greater design flexibility, lower cost, and reduced weight. The best option depends on your product’s end use.

Comparing properties: Metal parts are best for high tensile strength and heavy loads, but they often need anti-corrosion coatings and add significant weight. Plastics won’t rust, are up to 80% lighter, and support rapid design changes. For thermal needs, metals outperform most plastics; check Matmatch or AZO Materials for property data. Plastics win on cost per part for high-volume runs, as ThomasNet and Xometry explain. Both metals and plastics can achieve high precision—CNC machining for metals and injection molding for plastics.

If your part needs extreme strength, choose steel or aluminum; for complex, lightweight, or insulated parts, plastics often deliver better results at lower cost. For deeper case studies, read EngineeringClicks, Plastics News, and Plastics Technology Online.

In which of the following properties do plastic parts often compare favorably with metals?

It surprises many procurement managers how many key areas plastics outperform metals.

Plastics excel in weight, corrosion resistance, cost efficiency, noise dampening, and custom molding. These strengths make plastics the first choice for a growing number of industrial products.

Plastics are chosen for lightweight automotive panels to reduce fuel consumption (Auto Manufacturing News), and for pool pump housings that never rust even after years of use (WaterWorld). Custom electronic enclosures from Sony take advantage of plastic’s design freedom (Design News), and rapid tooling from Xometry accelerates new product launches. Plastic outlets and switch boxes dominate the market for safety reasons, backed by NFPA code. Large-scale fastener production often shifts to plastic for up to 40% savings (Fastener World).

A client in Australia moved to plastic HVAC fasteners, saving on both weight and total installed cost by skipping anti-corrosion steps. For more engineering data and plastics trends, use British Plastics Federation, Engineering Toolbox, Material Properties Database, or ResearchGate.

When to use metal or plastic electrical boxes?

Selecting the wrong material for an electrical box risks safety, code compliance, and longevity.

Use plastic electrical boxes for residential and light commercial work where corrosion resistance and insulation are required. Select metal boxes for high-traffic, high-heat, or code-critical installations.

Plastic boxes are standard for home wiring because they are light, easy to install, and don’t require grounding. UL standards specify metal for many industrial and commercial jobs due to impact and fire resistance. Leviton offers selection guides for both environments, and NFPA’s NEC details code requirements for each box type.

Most national codes provide clear rules for box material in each environment. For global safety and compliance, use resources from IEC and IEEE.

Advances in high-performance plastics mean even aerospace manufacturers, medical device companies, and automakers now use polymers for safety and weight reduction. GE and Ford integrate both metals and plastics for optimal product performance. Stay up-to-date with SME Manufacturing, Injection Molding Resource, Materialise, and Metalworking World Magazine.

Global B2B buyers demand certified quality, strong packaging, fast delivery, and stable logistics. Prime offers ISO-certified production, flexible custom packaging, strict QC, and fast global logistics. For packaging and export compliance, see Export.gov, FedEx export guide, UPS International Shipping, Alibaba Trade Assurance, and Global Sources logistics. Quality management details are available from ISO, SGS, TÜV Rheinland, and Intertek.

Prime’s engineers use SolidWorks Plastics and Autodesk Fusion 360 for design support. Prime complies with RoHS and CE Marking, and offers material traceability for every batch.

FAQs

What are the main advantages of plastic over metal? Plastics weigh less, resist corrosion, offer flexible design, and can lower your cost per part. Details here

When should I use metal instead of plastic? Choose metal for high-stress, high-heat, or fire-critical applications. See more

How do I select the best material? Consider end-use, required strength, environment, and budget. Read this guide

What certifications are needed for exports? Request ISO, RoHS, and relevant local certifications. More at ISO

How to get a quote from Prime? Email [email protected] or use our website. Response in 24 hours.

Can I mix metal and plastic parts in one order? Yes, Prime offers one-stop kits and assemblies.

How do I ensure packaging meets standards? Prime’s packaging follows export guidelines and is custom to your needs. Packaging tips

How does Prime control quality? Strict in-process and outgoing QC, plus full inspection reports. Our process

Conclusion

Choosing plastic or metal parts is key to your project’s performance, budget, and reliability. For certified, fast, and flexible B2B solutions, contact Prime.

Website: https://primecustomparts.com/

Email: [email protected]