Top 7 Custom Metal Parts for Industrial Applications You Should Know

Sourcing the right custom metal parts is tough—delays, low precision, or wrong specs can break your production line.

This article introduces the top 7 most-used custom industrial metal parts in industrial applications, alongside practical insights on manufacturing methods, material choices, and business value.

You shouldn’t waste hours comparing suppliers or decoding technical jargon. This guide breaks down real-world uses and production tips—all in plain English.

What are the 6 most common types of metal working?

When I started sourcing parts years ago, I didn’t realize how important metalworking methods were to the final product’s strength and cost.

Six core types of metal working shape the backbone of industrial manufacturing today.

- Stamping – Fast, repeatable, and perfect for high-volume custom sheet metal parts.

- CNC Machining – Ultra-precise. Great for complex or low-tolerance metal parts.

- Casting – Ideal for bulk parts with intricate internal structures.

- Welding – Used to join structures or reinforce stress-bearing assemblies.

- Forging – Produces ultra-strong parts, often used in automotive or aerospace.

- Extrusion – Best for long-profile components like rods or rails.

What is the most useful industrial metal?

Choosing the wrong material can cause corrosion, poor fit, or premature failure.

Among dozens of industrial metals, these three dominate across sectors.

- Steel – Strong, versatile, and relatively cheap. Used in everything from tools to construction.

- Aluminum – Lightweight and rust-resistant. Perfect for electronics and transport.

- Stainless Steel – Durable and corrosion-resistant. Common in food, pharma, and chemical settings.

At Prime, we often manufacture custom steel stamping parts and aluminum CNC components. Both materials balance performance and cost.

How to manufacture metal products?

Not all metal products are created equal. I’ve seen suppliers skip steps and deliver warped or under-toleranced items.

Metal manufacturing typically includes design, tooling, processing, and surface finishing.

Here’s how we do it at Shandong Prime:

- Design Review – Our engineers check your drawings and tolerance specs.

- Tooling Setup – We prepare dies or CNC programs for your project.

- Material Sourcing – Certified raw metals are chosen and cut.

- Processing – We stamp, cut, weld, or machine as needed.

- QC Inspection – ISO-based inspection at each stage.

- Surface Treatment – Coating, plating, or polishing if required.

- Packing & Shipping – Secure export packaging with full documentation.

Is metal fabrication a good business?

If you’re wondering whether to get into metal fabrication or outsource parts, you’re not alone.

Yes, metal fabrication is a profitable business—but only if you manage precision, delivery, and client trust.

Why?

- Industrial demand is growing worldwide.

- Large orders bring economies of scale.

- Customization allows premium pricing.

- Technical expertise builds loyalty and long-term contracts.

But success requires strict QC, modern machinery, and fast lead times. That’s where suppliers like Prime help scale quickly.

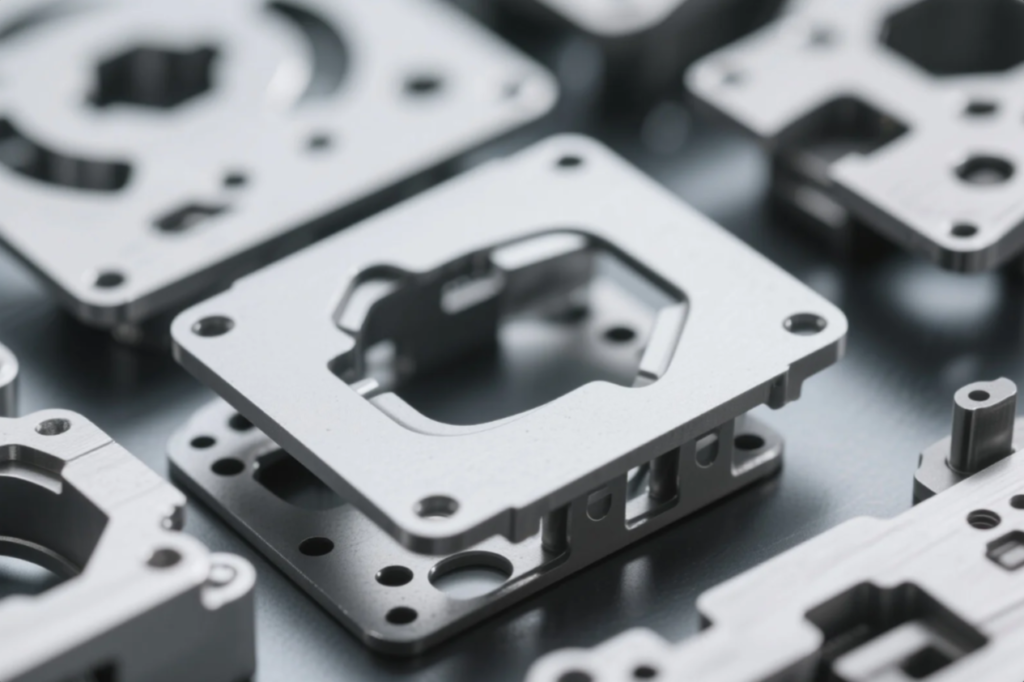

Top 7 Custom Metal Parts for Industrial Use

Now let’s focus on the parts themselves—here are the seven most in-demand industrial custom metal parts:

- Stamped Mounting Brackets – Found in HVAC, automotive, and robotics.

- CNC Milled Aluminum Enclosures – Used in electronics, control panels, and IoT devices.

- Forged Steel Flanges – Common in pipelines and heavy machinery.

- Welded Structural Frames – Key for industrial automation systems.

- Cast Iron Pump Housings – Essential for fluid systems.

- Fastening Components – Bolts, screws, and rivets used in every assembly.

- Laser-Cut Control Panels – Precision plates with ports and indicators.

These are parts we produce regularly at Prime, with full custom logo support, tight tolerances, and secure international shipping.

Frequently Asked Questions (FAQs)

Q1: What industries need custom metal parts the most?

A: Automotive, machinery, HVAC, electronics, and infrastructure lead in demand for custom components.

Q2: Can I order small batches?

A: Yes. Prime supports prototypes and small runs for trial orders or engineering testing.

Q3: Do you offer material certificates?

A: Yes. We provide full mill certificates and inspection reports with every order.

Q4: What is the lead time for CNC parts?

A: Usually 7–15 days depending on complexity and quantity.

Q5: How is Prime different from other suppliers?

A: We’re ISO-certified, own 10 production lines, and offer responsive English communication.

Conclusion

Get top-tier precision, delivery speed, and guaranteed quality by working with certified global suppliers.

📩 Ready to get your parts manufactured right the first time?

Contact Shandong Prime International Trade for free quotes, technical support, and fast sampling.

📧 Email us: [email protected]

🌐 Visit: https://primecustomparts.com/