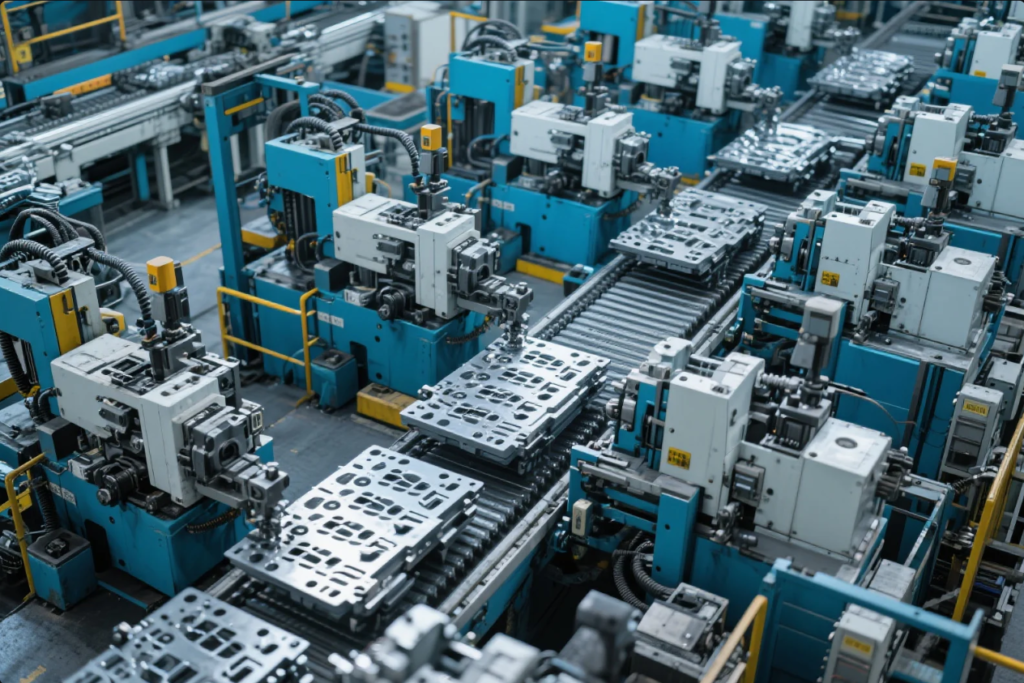

Top 8 Stamping Metal Components for Automotive and Machinery Use

Failing to choose the right stamping metal components can lead to fitment issues, durability failures, or costly recalls in automotive and machinery industries.

This guide introduces the top 8 stamped components used worldwide, and helps you understand which metals, steps, and standards deliver the best performance.

We also explore common materials, stamping processes, and the key considerations when sourcing custom stamped parts.

What is the best metal for metal stamping?

Choosing the right metal impacts strength, corrosion resistance, and formability of your stamped part.

Stainless steel and carbon steel are often the best metals for high-load parts.

For components that need high fatigue strength and rust resistance, 304 stainless steel is a top choice.

For general-purpose stamped brackets and frames, low-carbon steel (like SPCC or A36) is often preferred because it’s easier to form.

If weight matters, many suppliers use aluminum alloys for covers and lightweight parts.

What metal is used for stamping?

In industrial production, these metals dominate stamping applications:

- Cold Rolled Steel – Strong, cheap, widely available

- Stainless Steel (304, 316) – Corrosion-resistant, great for automotive

- Aluminum Alloys (5052, 6061) – Lightweight, easily shaped

- Brass – Good for decorative or electrical parts

- Copper – Best conductivity, but costly

- High-Strength Low-Alloy (HSLA) Steel – For safety parts under stress

Material choice depends on the part’s mechanical and environmental demands.

What are the 7 steps in the stamping method?

Metal stamping is more than just punching a shape. It’s a sequence of controlled operations.

The 7 steps in the metal stamping process are:

- Design Evaluation – CAD drawings reviewed for feasibility.

- Material Selection – Choose metal grade, thickness, and temper.

- Tooling Production – Dies are manufactured based on final shape.

- Blanking – Raw metal sheet is cut to initial form.

- Forming/Bending – Material is shaped through press force.

- Piercing/Coining/Embossing – Additional surface features added.

- Finishing & Quality Control – Deburring, coating, and inspection.

At Shandong Prime, we provide all 7 steps in-house, ensuring better accuracy and faster delivery.

What steel is best for stamping?

The best steel for stamping depends on what your application demands—strength, weldability, or flexibility.

Common steel grades used in stamping include:

| Grade | Description | Typical Use Cases |

|---|---|---|

| SPCC | Mild steel for general-purpose stamping | Enclosures, brackets, covers |

| AISI 1010 | Low carbon, easy to form and weld | Automotive panels, supports |

| AISI 1020 | Slightly stronger than 1010 | Frames, clips, medium-stress parts |

| 304 SS | Most common stainless steel | Exhaust covers, protective shields |

| HSLA | High strength with good ductility | Safety parts, crash-related components |

If your component will face corrosion or high heat, go with stainless steel 304 or 316. If it’s for structural support, HSLA or 1020 carbon steel offers better durability.

Top 8 Stamped Components Used in Automotive & Machinery

Here are the most common stamped parts buyers request at Prime, and why they matter:

- Mounting Brackets – Used to fix sensors, ECUs, modules, or panels.

- Reinforcement Plates – Add stiffness in suspension or chassis zones.

- Battery Terminal Contacts – Conductive stamped copper or brass elements.

- Heat Shields – Protect surrounding components from engine heat.

- Engine Covers – Usually aluminum, lightweight but rigid.

- Clips & Fasteners – Hold wiring harnesses or panels in place.

- Brake Backing Plates – Steel parts that support drum brake systems.

- Housing Flanges – Help seal pumps, valves, and gear enclosures.

These parts are all customizable at Prime, from material selection to packaging and surface finish.

FAQs: Sourcing Automotive Stamped Parts

Q1: Do I need a large MOQ to order stamped parts?

A: No. Prime supports small-volume orders, prototypes, and trial tooling.

Q2: Can you provide surface finishes like zinc coating or powder painting?

A: Yes. We offer plating, anodizing, e-coating, and custom finishes for all stamped parts.

Q3: What is your standard lead time for stamping orders?

A: Most parts ship within 10–15 working days, depending on complexity.

Q4: Are your stamped parts ISO certified?

A: Yes. We comply with ISO 9001 and offer full inspection reports, PPAP, and COC on request.

Q5: Can I customize packaging with my own labels and barcodes?

A: Absolutely. We provide barcode-ready cartons, inner bags, and export pallet solutions.

Conclusion

Stamped components are essential for safe, high-performance machinery. Partner with a certified supplier to ensure precision, strength, and reliability.

📩 Need high-quality stamped metal parts for your next automotive project?

Contact Shandong Prime International Trade for quick sampling, full customization, and global delivery.

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com