Top Custom Welding Service Providers for OEM and Industrial Applications

Welding plays a vital role in OEM and industrial manufacturing. Choosing the right provider affects quality, delivery, and ROI.

In 2025, top welding services offer OEM‑grade MIG, TIG, robotic, and laser welding with global export capabilities and strong certifications.

This comprehensive guide covers welding methods, equipment, costs, employment trends, and the leading 7 providers shaping industrial welding today.

Which Welding Methods Are Used by OEMs?

OEMs demand precision, speed, and repeatability. Common welding methods include:

- MIG (GMAW) – Fast, suitable for thick sections.

- TIG (GTAW) – High‑precision, ideal for stainless and thin materials.

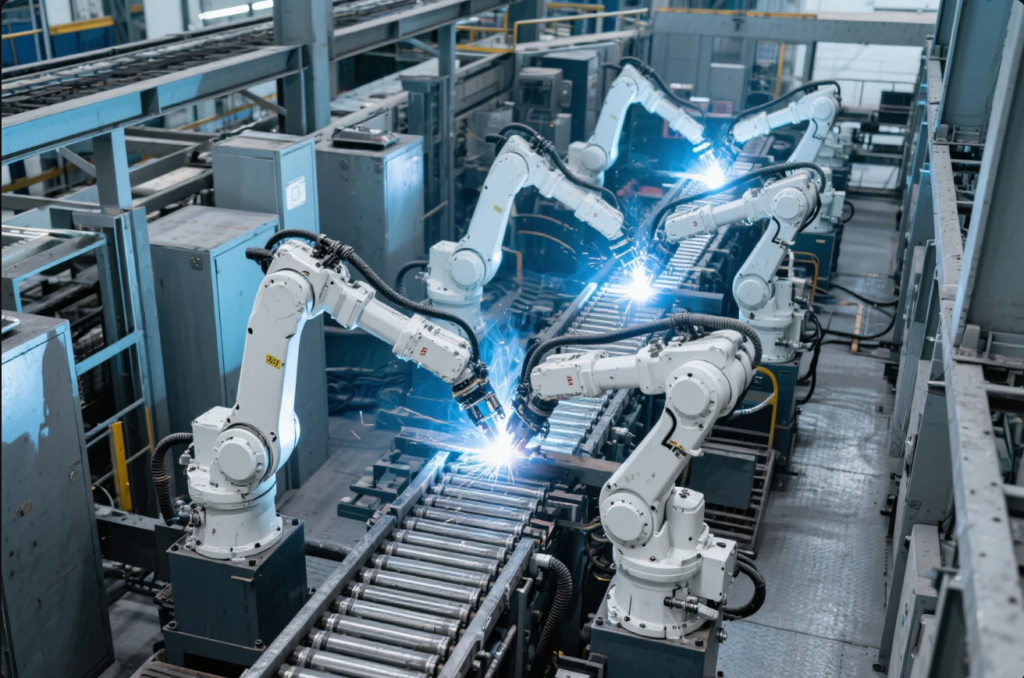

- Robotic Welding – Delivers consistency, efficiency, and scalability.

- Laser Welding – Minimal distortion with high-speed precision (see Trumpf laser welding).

- Friction Stir Welding (FSW) – Emerging in aerospace and EV sectors (check TWI FSW).

These methods meet diverse OEM needs across automotive, energy, machinery, and electronics sectors.

Who Is the Largest Manufacturer of Welding Equipment?

Supply chain strength is vital in welding. The top five global welding equipment manufacturers are:

- Lincoln Electric – Largest arc-welding and robotic solutions provider.

- Miller Electric – Innovative in consumer and industrial-grade machines.

- ESAB – Leading brand across arc and laser welding tools.

- Fronius – Pioneer in TIG welding with advanced quality control systems.

- CIGWELD (Weihai CIG) – Large Chinese OEM serving Asia-Pacific markets.

OEM integrators rely on these brands for quality and performance.

How Much Does Custom Welding Cost?

Custom welding pricing depends on various factors:

- Material – Stainless costs 30–50% more than mild steel.

- Process – TIG more expensive than MIG; robotic setups reduce per-part cost for volume.

- Labor – In China, technician rates average \$7–12/hour; in the US/EU, \$35–65/hour.

- Finish & QC – Shot blasting, powder coating, dimensional inspection add \$5–20/piece.

- Tooling – Custom fixtures add \$200–1,000 upfront, then spread over production volume.

Sample Price Estimates (FOB China):

| Part Type | Process | Qty | Cost Range (USD) |

|---|---|---|---|

| Mild steel bracket | MIG | 100 | \$20–\$30 |

| Stainless panel | TIG | 100 | \$45–\$65 |

| Robotic-welded chassis | MIG Robotic | 200 | \$50–\$120 |

| Custom housing + CNC trims | MIG + CNC + paint | 500 | \$75–\$150 |

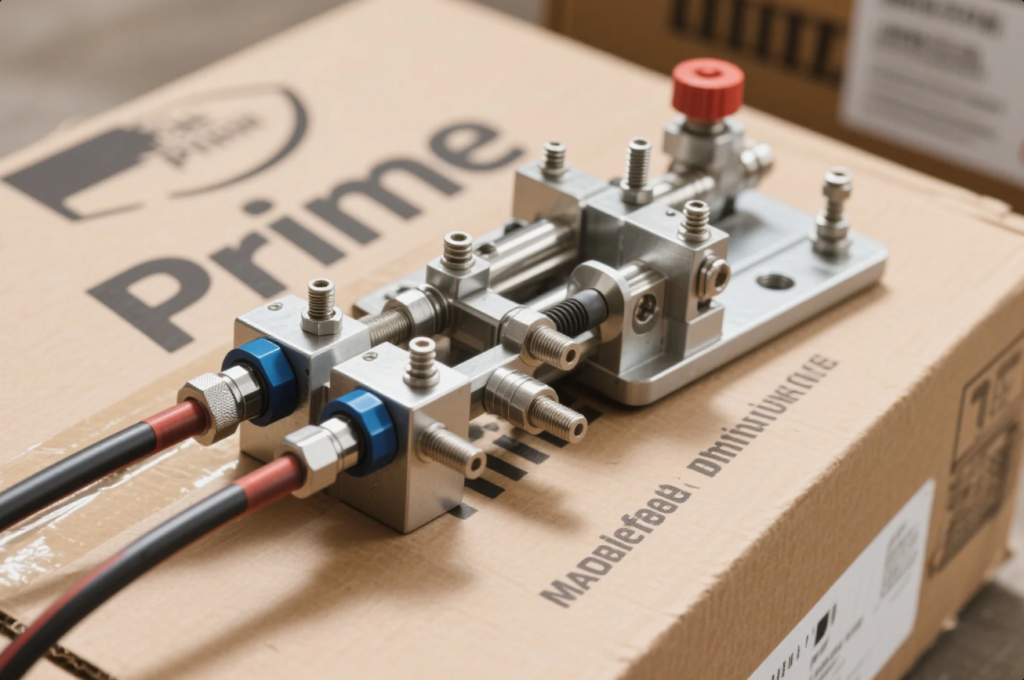

Larger volumes significantly lower unit price—Prime quotes typically arrive within 24 hours after receiving drawings.

Who Is the Largest Employer in Welding?

Welding remains a stable, well-paid global trade:

- The U.S. has \~454,500 welders with projected growth to 2032 (U.S. Bureau of Labor Statistics).

- The manufacturing sector employs over 60% of welders globally.

- In Canada, UK, EU, Japan, and Australia, welding employment has increased by 4–8% over the past five years.

- Welders today earn between \$48K–\$65K annually in North America, and \$15–\$30/hour in Europe.

This trade offers technical career paths, including QA, engineering, and management roles.

Top Custom Welding Providers for OEM

Here are seven top-rated welding providers recognized globally:

| Name | Country | Strengths |

|---|---|---|

| Prime Custom Parts | China | MIG/TIG/robotic welding, CNC finishing, global export |

| Lincoln Electric | USA | Welding equipment, robotic cells, training materials |

| Miller Electric | USA | Industrial & portable systems for varied OEM setups |

| ESAB | USA/Sweden | Global brand with arc, MIG, TIG, and robotic systems |

| Fronius International | Austria | High‑precision TIG and digital weld monitoring |

| Tianjin Golden Bridge | China | Weld wire + facilities for OEM steel welding |

| Voestalpine Böhler Welding | Austria | Advanced consumables and welding consulting |

These companies cover supply chain needs from equipment and welding services to consumables and consultancy.

Prime Custom Parts: Your OEM Welding Partner

Prime exports steel welded components to 40+ countries since 1993.

What sets Prime apart?

- 10 welding lines with MIG, TIG, spot, robotic stations

- AWS & ISO-qualified welders across materials

- In-house CNC trimming, coating, and packaging

- Fast RFQ (within 24 hours) and medium lead times (15–30 days)

- Export-ready with DDP/FOB/CIF terms

✅ Free DFM consultation—Send us your drawings today.

FAQs

Q1: Which welding process is best for OEM structural parts?

Automated MIG delivers strength and efficiency for large parts.

Q2: Can I source both equipment and welding service?

Yes—OEMs often bundle both. Prime recommends equipment and delivers finished parts.

Q3: Do robotic welds cost more?

Setup costs are higher, but unit costs lower significantly at volumes >200 pcs.

Q4: Are welders well paid?

Yes—average salaries range from \$50K–\$70K in developed markets.

Q5: How to verify welding quality?

Ask for certifications (ISO 3834, AWS), macro sections, and video/QC reports. Prime provides all.

Contact Prime

Partner with a certified OEM welding source—quality, speed, and global logistics.

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com

✔ RFQ turnaround within 24 hours

✔ Proof-of-concept samples available

✔ Free consultation and export-ready packaging