Understanding Welding Defects, Surface Treatments, and Best Practices for High-Performance Metal Parts?

Hidden weld defects, rapid corrosion, and unpredictable joint failures are common headaches for buyers and engineers sourcing metal parts worldwide. These challenges cost time, cause safety risks, and hurt reputations.

To deliver high-performance, long-life results, you must understand welding defects, select the right surface treatments, and follow best welding practices. This guide leverages global engineering references and real-world factory methods to help you avoid common pitfalls.

If your business depends on quality, traceability, and international compliance, keep reading for actionable advice with top industry resources and verification links.

Common Welding Defects in Metal Parts and How to Prevent Them

Welding defects are one of the biggest reasons for project failures and rejected batches. Most defects can be traced back to poor technique, improper setup, or low-quality raw materials. Learning the root causes and reliable prevention strategies is critical.

Key welding defects include porosity, cracks, undercut, incomplete fusion, spatter, and distortion. Each defect can be avoided by using clean metals, following a detailed Weld Procedure Specification, and hiring certified welders (American Welding Society).

Visit SGS’s welding QC page and QIMA’s weld inspection for independent quality control practices.

Table: Typical Welding Defects, Causes, and Prevention

| Defect | Typical Causes | How to Prevent |

|---|---|---|

| Porosity | Moisture, oil, rust, gas flow errors | Clean metal, dry rods, stable gas |

| Cracks | High restraint, rapid cooling | Preheat, controlled cool, joint design |

| Undercut | High amps, poor technique | Lower current, change torch angle |

| Incomplete Fusion | Low heat, poor access, oxide layer | Boost amps, clean joint, adjust prep |

| Spatter | Wrong polarity, too much current | Optimize settings, clean base |

| Distortion | Overheating, unbalanced weld | Alternate welds, fixturing, slow cool |

Dive Deeper: Global Best Practices for Defect Prevention

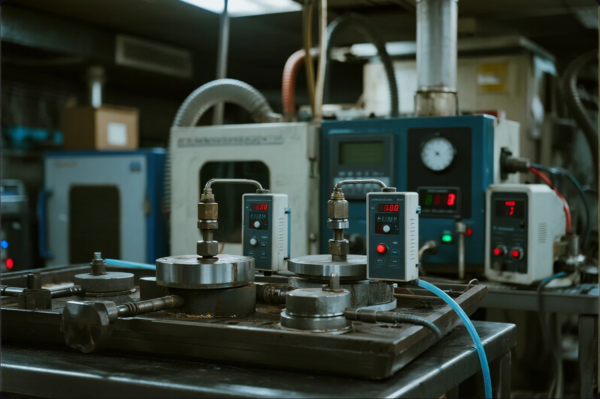

Factories certified to ISO 3834, EN ISO 5817, or AWS D1.1 log every weld, monitor key parameters digitally (Hexagon Manufacturing Intelligence), and run NDT with ultrasonic, X-ray, and dye penetrant inspection (Bureau Veritas, TÜV Rheinland). ImportYeti lets you research your supplier’s export record and past partners.

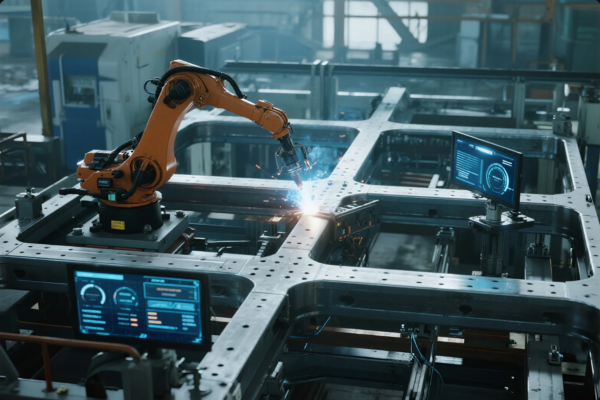

Top manufacturers invest in robotic welding (Fanuc Robotics, KUKA Robotics), and full weld traceability (GS1). The American Welding Society’s QC1 standard defines what to expect from certified welders.

For more industry commentary, see The Fabricator, WeldGuru, Thomasnet’s supplier guides, and Quality Magazine.

Surface Treatments for Welded Metal Parts: Galvanizing, Powder Coating, and More

Surface treatment is a must for any welded metal part exposed to moisture, chemicals, or abrasion. A strong weld can still rust or wear out fast if the surface is unprotected. Smart buyers choose finishes based on real-world demands.

Common finishing solutions include hot-dip galvanizing, electro-galvanizing, powder coating, wet painting, passivation for stainless, and nickel/gold plating. For global corrosion protection standards, reference ASTM B117 and ISO 12944. For detailed technical requirements, see Finishing.com, Coatings World, and PCI Powder Coating Institute.

Table: Surface Treatments for Welded Parts

| Surface Treatment | Ideal Use | Core Benefits | Key Resources |

|---|---|---|---|

| Hot-dip galvanizing | Outdoor, bridges, heavy steel | Thick zinc, long life | Galvanizers Association |

| Electro-galvanizing | Electronics, small parts | Smooth, detail, even coating | Zinc.org |

| Powder coating | Machinery, OEM, consumer goods | Durable, UV, color options | Axalta |

| Wet painting | Large, custom color, indoors | Flexible, affordable | Sherwin-Williams |

| Passivation | Stainless, medical, food | Anti-corrosion, hygiene | Poligrat |

| Plating | Electronics, decorative | Gold, nickel, tin, copper | MacDermid Enthone |

Dive Deeper: Integrating Finishing for Quality and Compliance

Prime and other leading factories treat finishing as a process step, not an afterthought. They prepare welds for coating adhesion, document color standards, and verify finish thickness and gloss (BYK-Gardner).

Factories perform salt spray tests, adhesion tests, and batch-traceable documentation (GS1). For regulatory peace of mind, ensure RoHS and REACH compliance.

In industries where appearance and hygiene are vital, such as food processing or medical, passivation or high-purity plating can make the difference. See Medical Device Network and Food Engineering Magazine for industry best practices.

Welding Process Optimization: Tips for Improving Strength and Durability

Without process control, even the best design will fail in the field. Welding process optimization combines engineering, equipment, and experienced operators to create lasting, strong welds every time.

Proven optimization methods include following a Weld Procedure Specification, using robotic automation, and digital parameter logging (Siemens MES). Always calibrate equipment (Lincoln Electric), use proper filler metal (The Fabricator), and select joint designs with reference to Miller Welds’ resource center.

Explore advanced guides at ESAB Knowledge Center, WeldGuru, Rockwell Automation, and Hexagon MI.

Table: Best Practices for High-Strength Welds

| Best Practice | Why It Matters | Reference/Resource |

|---|---|---|

| Use qualified procedures | Repeatable quality, compliance | AWS D1.1 |

| Calibrate all machines | Prevent drift, accurate output | Lincoln Electric |

| Optimize heat input | Avoids warping, weak joints | The Fabricator |

| Record digital QC data | Traceability, audits | Hexagon MI |

| Use smart fixturing | Consistency, less distortion | KUKA Robotics |

| Alternate weld patterns | Minimize distortion | Welding Design |

| Validate welders | Qualification, fewer defects | American Welding Society |

Dive Deeper: Digital Factories and Data-Driven Welding

Modern suppliers link welding with digital MES and ERP platforms (SAP ERP), supporting ISO 9001, IATF 16949, or EN 15085 compliance. QC teams use metrology from Mitutoyo and BYK-Gardner, while digital traceability enables full root-cause investigation when needed.

For extra assurance, buyers should require batch-level documentation, SGS or Bureau Veritas inspection, and open access to weld logs.

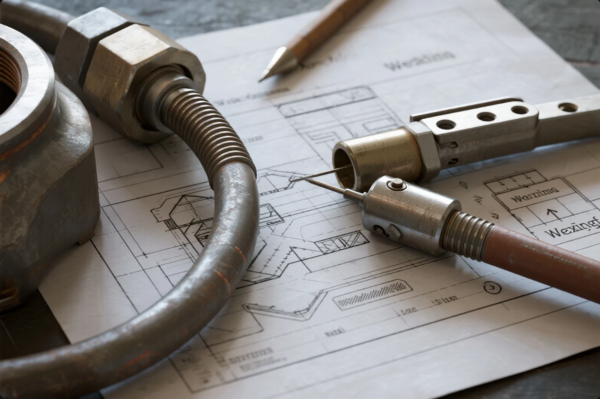

Design Considerations for Welding High-Performance Parts

Successful projects begin with thoughtful design. Engineers should specify weld joint types, access for welding torches, and control over distortion with proper fixturing. Share CAD files, SolidWorks, or Fusion 360 drawings, including tolerances and material certifications, with your supplier.

Use industry standards like ISO 2553 for weld symbols, EN 1090 for structural welding, and ASME BPVC Section IX for pressure vessels.

For more on weld-friendly design, check Engineering.com, The Fabricator, and WeldGuru.

Quality Assurance and Third-Party Testing

Quality assurance is not just a buzzword—it’s your guarantee that every batch meets your standards. Leading suppliers offer full digital traceability, from raw material certificates to SGS, QIMA, or Bureau Veritas third-party inspection. Ask for test reports, batch numbers, photos, and even video walkarounds.

Request NDT testing, ISO 9001 documentation, and EN 15085 or IATF 16949 compliance if required.

See more about inspection standards and quality trends at Quality Magazine, Thomasnet’s Quality Resources, and IndustryWeek.

Frequently Asked Questions About Metal Welding Parts

Q1: How can I check for hidden weld defects?

A: Request NDT testing, digital weld maps, and inspection photos. Use QIMA, SGS, or Bureau Veritas for third-party audits.

Q2: Which surface finish is best for outdoor welded parts?

A: Hot-dip galvanizing and powder coating protect against rust and UV. Follow ASTM B117 and ISO 12944 standards.

Q3: What causes most welding failures?

A: Weak joint prep, contamination, low heat input, or unqualified welders. Check AWS D1.1 guidelines and WeldGuru.

Q4: How can I ensure my supplier uses best practices?

A: Confirm ISO, EN, and AWS certification. Review SGS or [T

ÜV](https://www.tuv.com/world/en/) audit records, and check global references on ImportYeti.

Q5: Does Prime offer custom finishes and export packaging?

A: Yes. We provide powder coating, electroplating, export cartons (Packhelp), and GS1 barcoding (GS1) for global shipping.

Q6: What files or data should I submit for a quote?

A: Share AutoCAD, SolidWorks, or Fusion 360 drawings, material specs, finish, batch quantity, and target certifications.

Q7: Can Prime provide batch-level traceability and third-party inspection?

A: Yes. Prime delivers digital batch records, open QC files, and arranges inspection with SGS, QIMA, or Bureau Veritas.

Contact Prime

Ready to source high-performance welded parts with zero defects, world-class finishes, and fast delivery? Contact Prime for ISO-certified solutions and digital traceability from drawing to door.

Visit https://primecustomparts.com/ or email [email protected] for a free technical review, DFM advice, or global quotation. All requests are answered by engineers with proven industry experience.

Conclusion

Preventing weld defects, specifying finishes, and demanding transparent quality checks ensures reliable results. Trust global standards, digital traceability, and Prime’s engineering team to power your project’s success.