What are small metal pieces called?

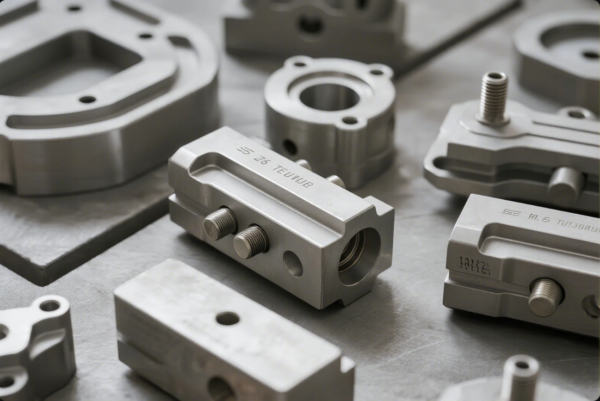

Image: Fine byproducts from CNC machining collected in Prime’s workshop.

In metal processing, tiny fragments left behind during cutting or drilling are more than waste—they reveal tool performance and material behavior.

These pieces may be known as chips, shavings, or filings, depending on their size and how they form. At Prime, we manage these with precision to ensure clean production and safe handling.

What are the small particles of metal?

These tiny remnants are common in milling, drilling, and grinding processes.

They can be:

- Spiral or curly in shape

- Powder-like in finish

- Microscopic when machining aluminum or titanium

Prime monitors these during production to assess tool sharpness and thermal behavior.

Summary:

Micromaterial created during machining reveals valuable production data and must be properly collected and managed.

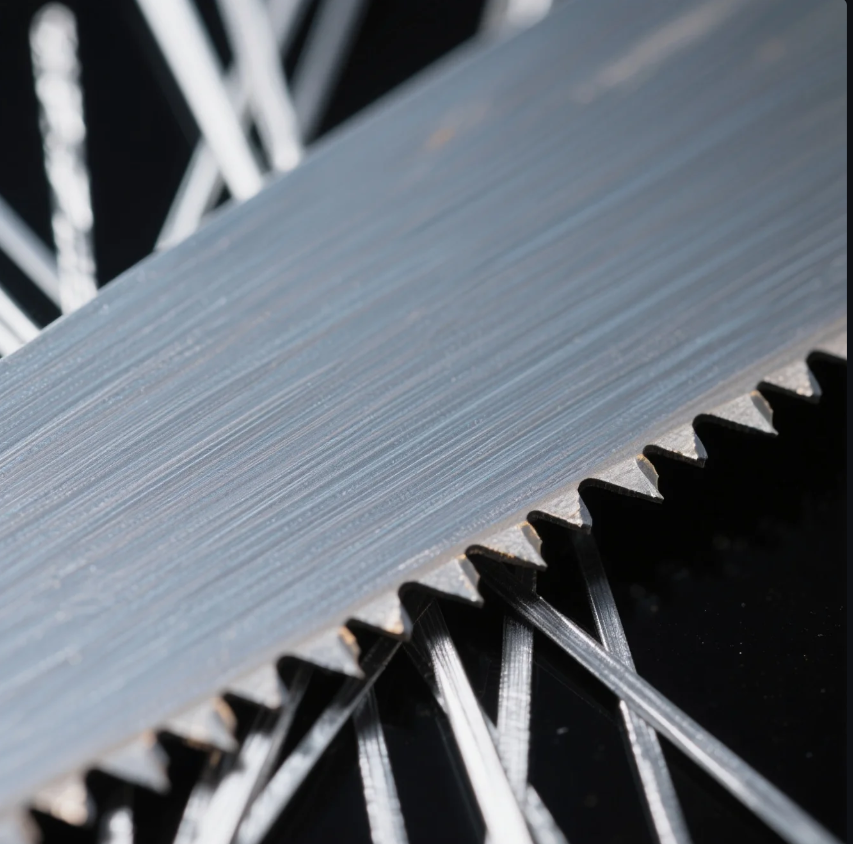

What are metal slivers?

A sliver refers to a thin, sharp strip created during cutting or shearing.

Common causes include:

- Rough trimming edges

- Poor burr removal

- Low feed or unstable tooling

At Prime, every part undergoes deburring and edge finishing to ensure no slivers remain before shipping.

Summary:

Sharp edge fragments are dangerous and must be removed before packaging. Prime addresses this during post-processing.

Why is it called swarf?

Swarf is a collective term for small metallic byproducts generated from shaping, cutting, or grinding.

It includes:

- Turnings

- Powder

- Fine spirals from lathes or mills

At Prime, we categorize and recycle this material—whether aluminum, brass, or steel.

Summary:

In modern shops, cutting waste is carefully collected, stored, and reprocessed.

What is a chunk of metal called?

Larger stock materials—used before machining—are called:

| Term | Description | Common Application |

|---|---|---|

| Billet | Rolled or extruded bar stock | CNC, extrusion |

| Blank | Flat, pre-cut sheet or slab | Stamping, laser cutting |

| Slug | Short, thick metal cylinder | Cold forging, coining |

| Ingot | Solidified casting block | Alloy melting, reprocessing |

Prime offers a wide range of aluminum, stainless steel, and carbon steel blanks for fast production cycles.

Summary:

Raw metal blocks are categorized by shape and application stage—forming the basis of CNC and stamping operations.

Frequently Asked Questions (FAQ)

❓ Is cutting debris recyclable?

Yes.

Properly sorted turnings and shavings can be melted and reused—especially for aluminum and brass.

❓ What’s the difference between burrs and slivers?

Burrs are raised edges left after machining.

Slivers are loose, narrow strips that detach from the edge.

❓ Can small fragments cause damage?

Yes.

Fine particles may cause contamination, equipment wear, or packaging punctures. Prime ensures debris-free delivery.

❓ Do all manufacturing processes create metal particles?

Not all.

Processes like casting or forming may produce fewer, but subtractive operations like CNC always result in fragments.

Conclusion

Whether they’re called chips, slivers, shavings, or swarf, these micro-residues are a natural part of industrial fabrication. At Prime, we manage them from start to finish—with safety, recycling, and clean packaging as top priorities.

Need precision parts without cutting waste or edge defects?

Contact Prime today for expert machining, clean surface finishing, and ISO-certified quality control.

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com