What Are Some Examples of Structural Elements?

Many clients struggle to define structural elements, which often causes design errors or procurement delays.

Structural elements are the foundational parts that provide shape, support, or logic to systems, whether mechanical or textual.

Understanding structure leads to better decisions. Keep reading or use the table of contents to navigate.

What Are the 4 Structural Elements?

Buyers often ask, "What are the basic structural parts in construction or machinery?" Confusion here can lead to incorrect designs.

The four structural elements are beams, columns, slabs, and foundations. Each plays a unique structural role.

In ISO-certified manufacturing, we match these with real components:

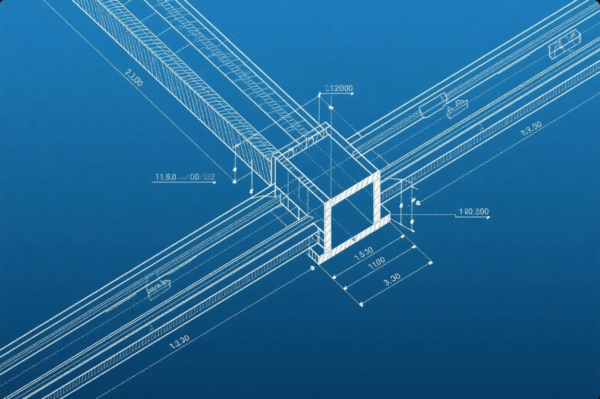

| Structural Element | Function | Material | Prime Example |

|---|---|---|---|

| Beams | Horizontal load support | Steel, aluminum | Stamped support beams |

| Columns | Vertical load bearing | Cast iron, steel | Cast load columns |

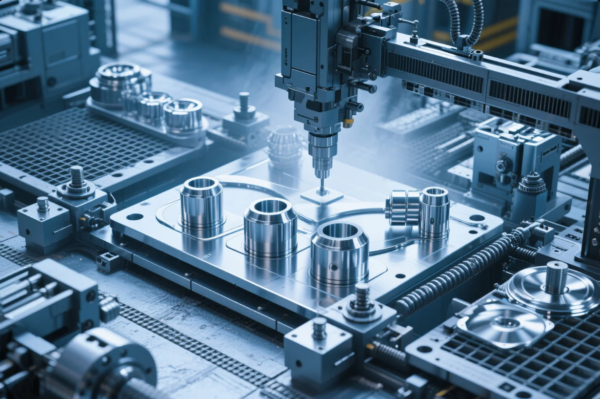

| Slabs | Flat surfaces or bases | Plastic, alloy | CNC-machined plates |

| Foundations | Transfer load to ground | Concrete, steel | Welded steel bases |

One German client needed high-tolerance CNC parts for structural beams. We customized alloys and ensured testing compliance under ISO standards. Delivery was on time.

What Are Structural Elements in Literature?

Unclear writing can confuse readers. That’s why I use literary structural concepts to improve technical content.

Structural elements in writing include plot, setting, characters, and theme. They also guide business communication.

| Literary Element | Business Equivalent | Purpose |

|---|---|---|

| Plot | Product story | Shows value or need |

| Setting | Usage environment | Builds context |

| Characters | Customer profiles | Enhances relatability |

| Theme | Core message | Drives retention |

In a case study for our custom stamping parts services, we structured the story with client pain points (plot), industrial use case (setting), customer roles (characters), and final benefits (theme).

What Is Meant by Structural Elements?

"Structural elements" means different things in various industries. Clarifying it boosts team alignment.

A structural element is any part that holds shape, bears load, or enables functional flow.

| Context | Structural Elements | Example | Prime Match |

|---|---|---|---|

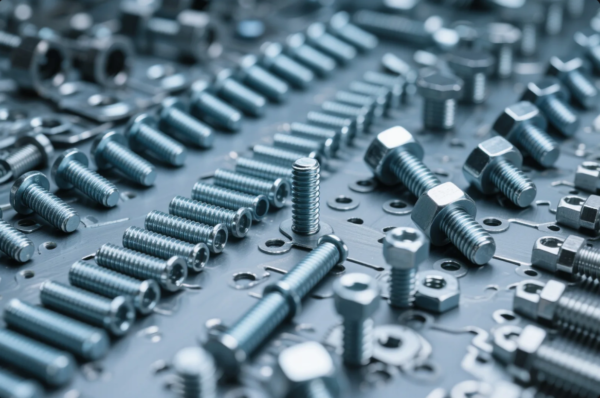

| Mechanical | Frames, casings, fasteners | Industrial fasteners | Screws, bolts |

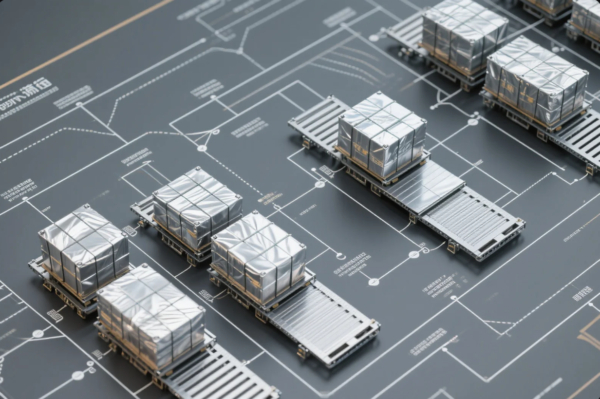

| Logistics | Warehousing, supply links | SCM processes | Export-ready packaging |

| Documentation | Paragraphs, lists, headings | Technical blogs, manuals | Project datasheets |

One Australian client wanted better packaging. We provided a packaging diagram and optimized based on real structure flow.

What Are the Structural Elements of an Argumentative Text?

A solid argument needs more than a statement—it requires structure.

Argument structure includes claim, evidence, counterclaim, and conclusion. Each adds clarity and credibility.

| Argument Part | Business Use | Example |

|---|---|---|

| Claim | Product value claim | "We meet ISO 9001" |

| Evidence | Data or case studies | Delivery history logs |

| Counterclaim | Address concerns | "Higher price, better ROI" |

| Conclusion | CTA or summary | "Request a sample" |

In one proposal to a European buyer, we added quality certificates as evidence. Then we addressed price doubts with long-term savings.

Prime’s Expertise in Industrial Structural Parts

Founded in 1993, Prime has delivered to clients in over 30 countries. We focus on B2B metal components.

Our advantages include ISO certification, 10 production lines, and 20+ years of one-stop service.

- ISO Certification (Details)

- 10+ In-house Lines (Manufacturing.net)

- Stamping, CNC, Welding (Wikipedia)

- Custom Tolerance Solutions (Engineering.com)

- Certified Packaging Standards (IPPC)

- Reliable Global Logistics (UPS, DHL)

- Multilingual Sales Support (Alibaba)

- Flexible Payment Terms (Trade.gov)

We’ve worked with OEMs, engineers, and sourcing agents from North America, Europe, and Australia.

FAQs

Q1: Do you offer samples? Yes, prototypes available upon request.

Q2: What’s your MOQ? Typically 5,000 for stamping; 1 unit for CNC/casting.

Q3: What are the lead times? 2–4 weeks depending on quantity.

Q4: What materials do you use? Steel, aluminum, copper, plastics like ABS, POM.

Q5: Do you provide inspection reports? Yes, internal and third-party reports available.

Q6: What are your shipping methods? By air, sea, or express (DHL, FedEx, UPS).

Q7: Do you follow packaging protocols? Yes, IPPC-certified packaging for export.

Q8: What payment options do you support? T/T, L/C, Alibaba Trade Assurance.

Conclusion & Contact Info

Clarity in structure leads to better outcomes—mechanical or strategic.

For structural parts that meet ISO standards with fast delivery, contact Prime:

Website: https://primecustomparts.com

Email: [email protected]

Request a free quote, sample, or expert consultation today.