What Are the 5 Uses of Plastic in Industrial Applications?

Plastic is one of the most versatile materials in modern manufacturing—used across nearly every industry on the planet.

Plastic is used in automotive, electronics, medical, packaging, and construction industries. These applications rely on plastic’s low cost, light weight, flexibility, and ability to be molded into precise shapes.

This article explores the top 5 uses of plastic in real-world industrial and commercial settings. We\’ll also cover 10 specific examples, molding applications, and the most common plastic types used today.

What Are the 10 Uses of Plastics?

Plastics are used in thousands of ways, but these 10 examples show how essential they are to both consumers and industries.

The top 10 uses of plastics include packaging, automotive parts, consumer electronics, medical disposables, construction materials, kitchenware, toys, insulation, safety equipment, and agriculture.

Real-World Plastic Applications

| — | ||||||

|---|---|---|---|---|---|---|

| Packaging | Bottles, wrappers, caps | PET, HDPE, LDPE | ||||

| Automotive | Bumpers, dashboards, fuel tanks | ABS, PP, Nylon | ||||

| Electronics | Housings, cables, displays | PC, PVC, PS | ||||

| Medical | Syringes, IV bags, test tubes | PE, PP, PVC | ||||

| Construction | Pipes, insulation, roofing sheets | PVC, UPVC, EPS | ||||

| Kitchenware | Containers, utensils, storage bins | HDPE, PP | ||||

| Toys | Figurines, learning kits, sports items | LDPE, ABS | ||||

| Insulation | Foam panels, pipe wraps | XPS, EPS | ||||

| Safety Gear | Helmets, gloves, goggles | PC, ABS, Nylon | ||||

| Agriculture | Drip lines, mulch films, crates | PE, PP |

At Prime, we\’ve supplied custom-molded automotive clips, food-grade containers, and irrigation accessories to clients worldwide. All parts are produced under ISO quality systems to ensure reliability and safety.

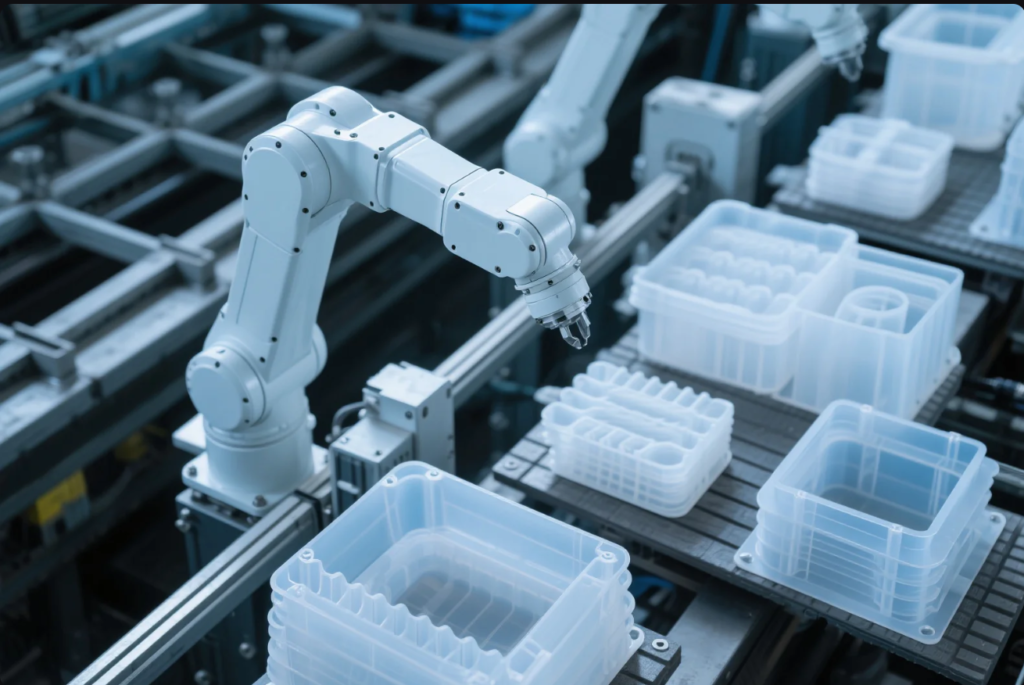

What Are the Applications of Plastic Molding?

Plastic molding is the method behind most plastic products you use every day.

Plastic molding is used in industries such as automotive, electronics, packaging, medical, and furniture. It enables the creation of precise, high-volume parts with excellent surface finish and mechanical strength.

Applications of Plastic Molding

| — | ||||||

|---|---|---|---|---|---|---|

| Automotive | Grilles, switches, bezels | Injection molding | ||||

| Medical | Syringes, trays, device enclosures | Cleanroom molding | ||||

| Packaging | Caps, bottles, jars | Blow molding | ||||

| Furniture | Chair shells, drawers, clips | Structural foam molding | ||||

| Electronics | Remote cases, battery covers | Injection & insert molding |

Prime’s injection molding capabilities allow us to provide tailored solutions for OEMs looking for high-strength, lightweight, and dimensionally accurate components—especially for global export.

What Are the Applications of Plastic?

The term "applications of plastic" covers everything from tiny medical valves to massive construction panels.

Plastic is used in the production of components that require impact resistance, corrosion protection, insulation, or lightweight properties. Common sectors include healthcare, telecom, logistics, energy, and retail.

### Functional Plastic Applications Across Sectors

### Functional Plastic Applications Across Sectors

- Telecom: Antenna covers, router housings

- Retail: Display shelves, signs, hangers

- Energy: Solar panel backing sheets, cable sheaths

- Logistics: Crates, pallets, shrink wraps

- Defense: Tactical gear, drone casings

Prime supports global buyers with custom-designed molded enclosures for electronics, and UV-resistant exterior panels for solar equipment in hot climates like the Middle East and Australia.

What Are the Most Common Plastics Used?

Choosing the right plastic depends on function, environment, and cost. These are the most widely used types in industry today.

The five most common industrial plastics are polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), and acrylonitrile butadiene styrene (ABS). Each has different properties and applications.

Overview of Common Plastics

| — | ||||||

|---|---|---|---|---|---|---|

| PE | Lightweight, flexible | Packaging film, tubing, toys | ||||

| PP | Fatigue-resistant, chemical safe | Auto parts, containers, hinges | ||||

| PVC | Durable, flame retardant | Pipes, windows, cable insulation | ||||

| PS | Hard but brittle | Disposable cutlery, CD cases | ||||

| ABS | Tough and impact-resistant | Helmet shells, appliances, dashboard trims |

We’ve shipped over 1 million ABS plastic parts for automotive clients across Europe. These parts require tight tolerances and perfect surface finishes—achieved using precision injection molding and post-mold QC.

FAQs

Q: What is the difference between PE and PP?A: PE is more flexible and used in films. PP is more rigid and heat-resistant, ideal for containers and automotive parts.

Q: Can plastics be used for structural parts?A: Yes, plastics like reinforced nylon, ABS, and polycarbonate are used in structural applications like dashboards, enclosures, and frames.

Q: Are molded plastics recyclable?A: Most thermoplastics (e.g., PE, PP, PET) can be recycled. Thermosets are not recyclable once cured.

Q: What’s the most cost-effective plastic?A: LDPE and PP are among the most affordable plastics due to wide availability and simple processing.

Q: How do I know which plastic is right for my part?A: Consider strength, flexibility, heat resistance, and environment. Or consult experts like Prime for free material recommendations.

Conclusion

Plastic has revolutionized modern manufacturing, offering low-cost, versatile solutions across industries. From automotive and packaging to electronics and construction, plastic’s role is unmatched in functionality and design flexibility.

At Shandong Prime International Trade Co., Ltd., we provide custom-molded plastic parts under ISO-certified systems with fast delivery and strict quality control. With 10 production lines and 20+ years of export experience, we’re your reliable plastic component partner.

📩 Email us at [email protected]🌐 Visit https://primecustomparts.com for free consultation, quotes, and expert design support.