What Are the Applications of Welding?

Introduction: Why Welding Applications Matter in Modern Industry

In today’s industrial world, welding shapes every aspect of infrastructure and product design. If you walk into a major factory, you’ll see welding robots, manual stations, and inspection labs—each essential for modern production.

Reliable welding underpins the construction of bridges, power plants, rail systems, and automotive factories. Global brands rely on certified welds for safety and long-term durability. As more buyers turn to digital sourcing on DirectIndustry, choosing the right supplier is critical.

What Is the Application of Welding?

Welding is present in nearly every manufactured product. In automotive assembly, robots spot-weld car frames for strength and speed. In pipeline construction, long seam welds ensure gas and oil stay contained under extreme pressure.

In shipyards, skilled welders create water-tight hulls, while energy companies build wind towers and turbines using multi-pass welds for structural integrity.

Construction engineers rely on welded beams and rebar cages for bridges and skyscrapers. In consumer electronics, micro-welding joins precision contacts and battery tabs.

These applications demand not only the right welding process but strict quality control, following standards from AWS and ISO.

What Are the Special Welding Applications?

Advanced industries use specialized welding to solve complex problems. In medical device production, ultra-clean TIG or laser welding joins titanium parts, ensuring no contamination or microcracks. Nuclear power plants require orbital welding for high-purity piping. Aerospace suppliers rely on vacuum welding for lightweight yet high-strength assemblies.

Food industry engineers specify crevice-free welds on stainless for hygiene. Electronics manufacturers use micro-welding for sensitive connections. Even architects design public art that depends on beautiful, durable welded joints.

Prime regularly passes audits by TÜV SÜD and SGS for medical, food, and high-tech projects.

What Is the Application of Butt Welding?

Butt welding is critical for joining parts end-to-end in heavy infrastructure and transport.

In pipeline networks, automatic butt welding joins miles of oil and gas pipe. Rail builders use flash-butt welding for smooth, safe tracks. Structural steel fabrication relies on butt welds for columns and beams.

Battery production and pressure vessel fabrication both rely on quality butt welds for safety and durability.

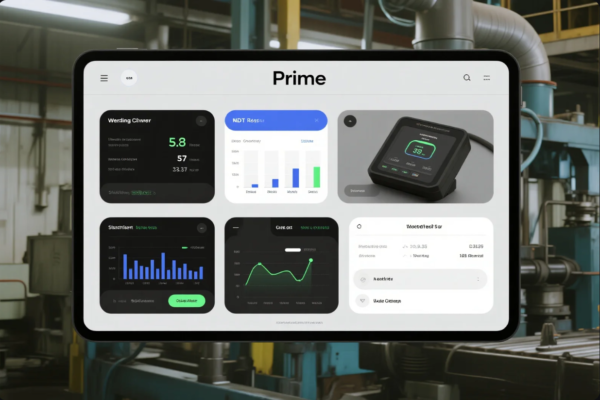

Prime uses real-time sensors, digital weld logs, and certified operators to meet ASME and ISO 9001 standards for global customers.

What Is Welding Application and Practice?

Application means selecting the right welding process, joint design, and quality procedure for each job.

Modern best practice, as taught by Miller Welds and ESAB, includes careful material matching, pre-cleaning, fixturing, and parameter control.

Prime’s welding engineers often reference Lincoln Electric and ASM International for best-in-class guidance.

NDT—such as ultrasonic, X-ray, or dye-penetrant—is crucial for critical welds.

Traceability and documentation are required for EN 15085, ASME BPVC, and SGS audits.

Deep Dive: How Prime Delivers Welding Solutions for Global Buyers

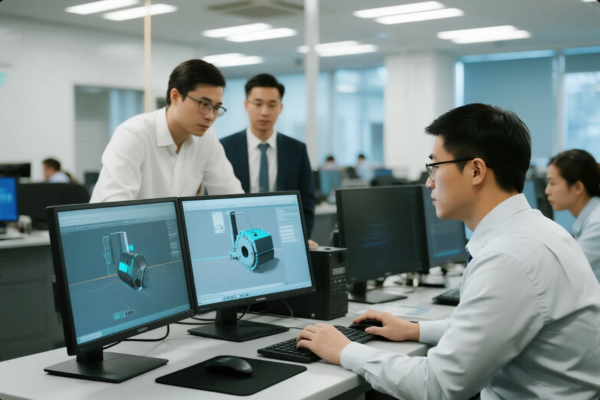

Each project at Prime begins with simulation using SolidWorks and ANSYS.

We review material certificates from Baosteel, ArcelorMittal, and third-party labs. Our robotic lines and skilled teams support both high-volume production and low-volume custom projects.

A recent export for a renewable energy client required over 1,500 welded wind tower sections, each batch traced, GPS-logged, and NDT-inspected per TÜV SÜD protocols.

We use Maersk and DHL for global, damage-free logistics.

Real-World Buyer Pain Points and Trends

Modern buyers worry about delays from poor welds, untraceable batches, and supply chain disruptions. Missed deadlines from rejected shipments are common, especially when suppliers lack digital QA, certified inspection, or compliant packaging for global shipping.

With market leaders using robotics, digital tracking, and ISO 14001 for sustainability, it’s vital to choose suppliers with automated lines, detailed documentation, and multi-country delivery experience.

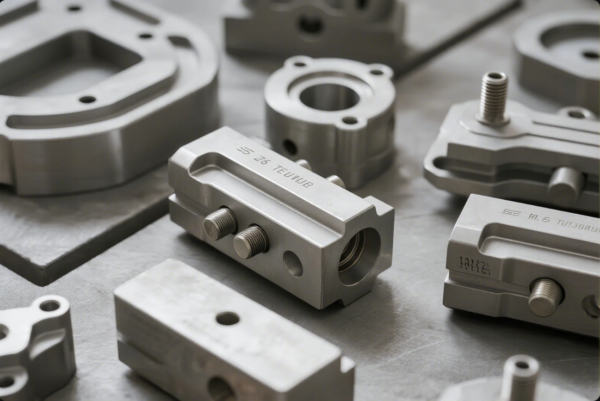

Image Gallery: Welding in Real-World Applications

FAQs: Welding Applications for Industrial Buyers

Which welding process is best for automotive frames?

MIG and spot welding, as used by global OEMs.

Can you weld dissimilar metals in volume?

Yes—friction or explosion welding, following TWI Global.

What is critical for food industry welding?

Stainless, smooth welds, and hygiene—Food Engineering.

How does Prime ensure traceability?

Batch logging, digital QA, and SGS or TÜV SÜD audits.

Can Prime support prototyping and mass production?

Yes, using flexible automation and quick changeovers, like leading DirectIndustry suppliers.

Conclusion: Unlock Your Competitive Edge with Prime

Welding drives every major industry—automotive, energy, medical, food, and beyond. Prime delivers certified, data-driven, and global-ready solutions, trusted by Alibaba, Global Sources, and Thomasnet.

Rely on our expertise for your next custom, high-spec, or large-scale project.

Contact Prime for Technical Support & Free Consultation

- Website: https://primecustomparts.com/

- Email: [email protected]

- Alibaba: PrimeCustomParts on Alibaba

- Global Sources: PrimeCustomParts on Global Sources