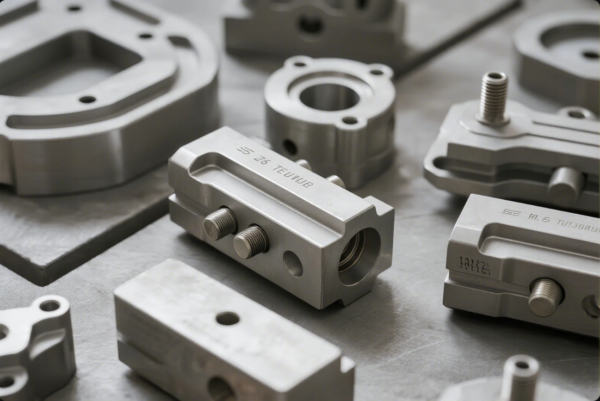

What Are the Basic Mould Parts?

Understanding the basic mould parts is essential for anyone involved in manufacturing, especially in processes like stamping, forming, and embossing. These components work together to shape and form materials into desired products.

Snippet paragraph: Basic mould parts include the die, punch, stripper plate, and guide pillars, each playing a crucial role in shaping materials during manufacturing processes.

Let’s delve into the primary components that make up a mould and their functions.

📚 Table of Contents

- Is Embossing the Same as Stamping?

- What Is the Difference Between Stamping and Forming Metal?

- What Is the Difference Between Embossing and Engraving Metal?

- What Metal Do You Use for Embossing?

- FAQs

- Contact Prime for a Material Consultation

Is Embossing the Same as Stamping?

Embossing and stamping are both techniques used to shape materials, but they serve different purposes and involve distinct processes.

Snippet paragraph: Embossing raises a design on a material’s surface for decorative purposes, while stamping cuts or shapes material using dies for functional components.

Dive Deeper: Embossing vs. Stamping

Embossing involves creating a raised or recessed design on a material’s surface, often for aesthetic appeal. This is achieved by pressing the material between matched male and female dies. Stamping, on the other hand, uses a die and punch to cut or form material into specific shapes, commonly used in manufacturing parts like brackets or enclosures.

| Process | Purpose | Technique | Common Uses |

|---|---|---|---|

| Embossing | Decorative enhancement | Pressing design into material | Invitations, packaging, signage |

| Stamping | Functional part creation | Cutting or forming with dies | Automotive parts, electronics |

What Is the Difference Between Stamping and Forming Metal?

While stamping is a type of forming, not all forming processes are stamping. Understanding their differences is key to selecting the right manufacturing method.

Snippet paragraph: Stamping is a specific forming process using dies to shape material, whereas forming encompasses various methods like bending, rolling, and forging.

Dive Deeper: Stamping vs. Other Forming Methods

Stamping specifically refers to using a press and die to cut or shape materials. Other forming methods include:

- Bending: Deforming material along a straight axis.

- Rolling: Reducing thickness by passing material through rollers.

- Forging: Shaping material using compressive forces, often at high temperatures.

Each method serves different purposes and is chosen based on the desired outcome, material properties, and production volume.

What Is the Difference Between Embossing and Engraving Metal?

Embossing and engraving both add designs to materials but in contrasting ways.

Snippet paragraph: Embossing creates raised designs by pressing material between dies, while engraving involves cutting into the material to create recessed patterns.

Dive Deeper: Comparing Embossing and Engraving

Embossing uses matched dies to press a design into material, creating a raised effect. Engraving removes material from the surface using tools or lasers to create detailed, recessed designs.

| Feature | Embossing | Engraving |

|---|---|---|

| Design Effect | Raised (or recessed) patterns | Recessed lines or grooves |

| Technique | Pressing with dies | Cutting or etching into the surface |

| Detail Level | Moderate | High |

| Common Uses | Decorative panels, nameplates | Jewelry, plaques, intricate designs |

What Metal Do You Use for Embossing?

Selecting the right metal is essential for successful embossing.

Snippet paragraph: Common metals for embossing include aluminum, copper, and brass due to their malleability and ability to retain detailed designs.

Dive Deeper: Suitable Metals for Embossing

- Aluminum: Lightweight and malleable, ideal for detailed embossing.

- Copper: Offers a rich color and is easy to work with.

- Brass: Combines strength with workability, suitable for decorative items.

These metals are chosen for their ability to undergo deformation without cracking, ensuring crisp and lasting embossed designs.

FAQs

Q1: Can embossing be done on stainless steel?

A1: Yes, but it requires more pressure due to the metal’s hardness.

Q2: Is stamping suitable for high-volume production?

A2: Absolutely, stamping is ideal for mass-producing consistent parts.

Q3: Which process offers more design detail, embossing or engraving?

A3: Engraving provides finer detail, while embossing offers a more tactile design.

Q4: Are there limitations to the thickness of metal for embossing?

A4: Thinner metals are preferable for embossing to achieve clear designs.

Q5: Can both embossing and stamping be used on the same piece?

A5: Yes, combining both can add functional and decorative elements.

Contact Prime for a Material Consultation

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com

Need guidance on the right metal for your project? Prime offers expert insights, global sourcing, and high-quality production—backed by 20+ years of experience and ISO-certified systems.

Conclusion

Understanding the basic mould parts and the differences between embossing, stamping, and engraving is crucial for selecting the appropriate manufacturing process. Each technique offers unique advantages, and choosing the right one depends on the desired outcome, material, and production volume.