What are the disadvantages of 3D metal printing?

Buyer: I’ve seen all the hype around metal 3D printing, but I need to know—what are the disadvantages of 3D metal printing?

Engineer (Prime): That’s a smart question. While metal additive manufacturing has huge potential, it also comes with real challenges—especially when it comes to cost, process stability, and part reliability.

Let’s go through them.

What are the cons of 3D metal printing?

Buyer: Let’s start with basics—what are the main downsides?

Engineer: Here are the big ones:

- 🧱 High cost — Metal printers cost \$250K+, plus post-processing tools

- 🧪 Process complexity — Needs tight control of oxygen, powder, laser path

- ⚙️ Support removal — Labor-intensive and may damage the part

- ⏳ Slow speed — One layer at a time = long build cycles

- 🧯 Safety risks — Metal powder is flammable and requires special handling

Buyer: So it’s not plug-and-play like an FDM printer?

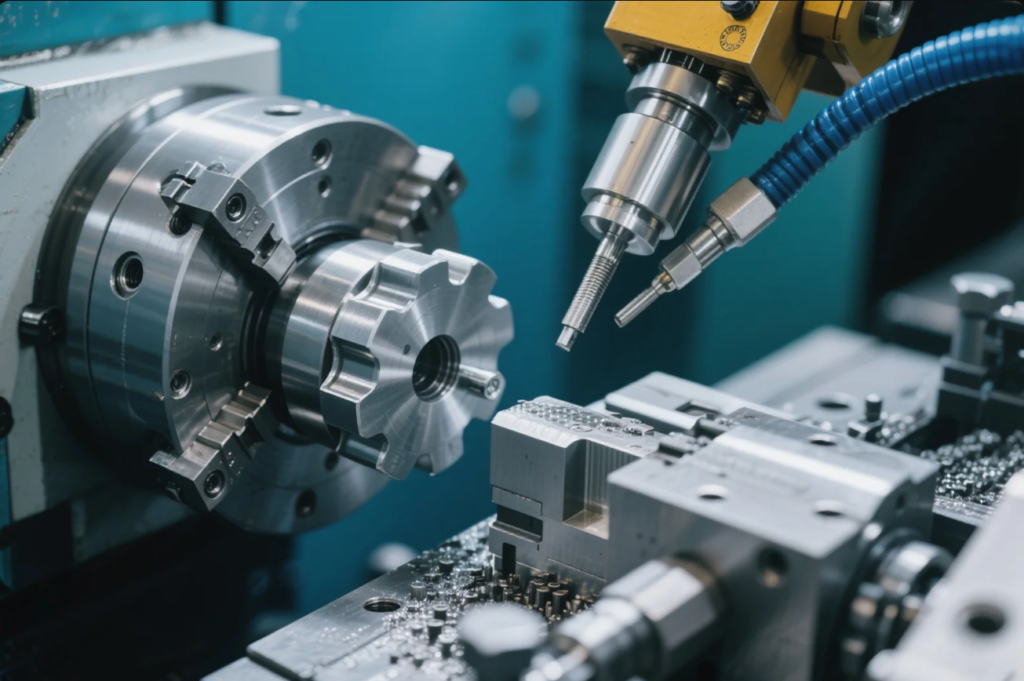

Engineer: Not even close. That’s why Prime handles printing, heat treatment, machining, and inspection for clients who want the benefits without the risk.

What are the problems with metal printing?

Buyer: Aside from cost and complexity, what actually goes wrong with parts?

Engineer: Great point. Common problems include:

- Porosity — Tiny air pockets reduce strength

- Residual stress — Parts warp or crack due to heat cycling

- Surface roughness — As-printed finish is rough and often needs machining

- Incomplete melting — Leads to weak bonding between layers

- Geometry distortion — Overhangs and unsupported zones sag

At Prime, we use CT scanning and simulation to catch these risks before shipping parts to clients in aerospace, robotics, and medical.

Summary: Even with good equipment, metal printing requires expert tuning to avoid costly failures.

Is metal 3D printing worth it?

Buyer: With all these disadvantages—why use metal printing at all?

Engineer: Because when it works, it can do what no other process can:

- Combine light weight + strength

- Print internal channels, lattices, or complex geometries

- Reduce multi-part assemblies into one part

- Enable faster prototyping of metal components

But it only pays off when:

- Part volume is low

- Design complexity is high

- Traditional tooling would be too costly

- You can accept longer lead time and higher per-part cost

Buyer: So for the right application—it’s worth it.

Engineer: Exactly. At Prime, we help clients decide if printing is right—or if CNC or casting is more cost-effective.

What metals cannot be 3D printed?

Buyer: Can you print any metal?

Engineer: No. Here’s where it gets tricky.

Common printable metals:

- Titanium (Ti64)

- Stainless steel (316L, 17-4PH)

- Aluminum (AlSi10Mg)

- Inconel (nickel alloys)

Difficult or non-printable metals:

- Pure copper — Reflects lasers; requires green-laser systems

- Tool steels — Crack easily unless carefully treated

- Magnesium — High flammability

- Zinc alloys — Low melting point leads to vaporization

Buyer: So even if the machine exists, the material may not be compatible?

Engineer: Correct. And at Prime, we match your application with the safest and most stable printable alloys.

Frequently Asked Questions (FAQ)

❓ Can metal 3D printed parts replace forged parts?

Engineer: Not always. Forged parts are stronger, especially under cyclic stress. Printed parts are best for complex, lightweight, or low-volume parts.

❓ Is metal printing good for production?

Engineer: It’s better for prototyping or low-volume runs (10–500 pcs). For mass production, CNC or casting is faster and cheaper.

❓ How long does it take to print a metal part?

Engineer: A small part can take 5–12 hours. Larger builds may run for 2–3 days, depending on geometry and material.

❓ Do printed metal parts need heat treatment?

Engineer: Yes. Stress relief or Hot Isostatic Pressing (HIP) is often required to reach full mechanical strength.

Conclusion

Buyer: So what are the disadvantages of 3D metal printing?

Engineer: Mainly cost, complexity, porosity risk, and post-processing time. But for the right parts, it’s a game changer.

Buyer: Good to know. I’ll reach out to Prime before I commit to printing or machining.

Engineer: Smart move. We’ll help you evaluate geometry, material, and volume—and recommend the best process.

Looking to compare metal printing, CNC machining, or casting?

Contact Prime for a free quote, printability review, or DFM consultation.

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com