What are the disadvantages of stamping and how can they be avoided?

Stamping offers speed and precision—but only when its risks are properly managed.

The main disadvantages of stamping include die wear, design rigidity, safety hazards, and material limitations.

Here’s what to watch out for—and how to overcome these challenges with the right supplier.

LOOP_START

What are the hazards of stamping?

Stamping machines can be dangerous without the right protections in place.

Stamping operations pose risks such as crush injuries, tool misalignment, and material ejection.

Common safety hazards

| Hazard Type | Description |

|---|---|

| Pinch & Crush Points | Hands or limbs caught in moving press parts |

| Ejection Injuries | Parts or scrap ejected at high speed |

| Noise Exposure | Repeated cycles generate unsafe noise levels |

| Die Maintenance Risks | Changing or cleaning dies without proper lockout/tagout protocols |

How Prime ensures stamping safety

We operate fully guarded, servo-driven stamping lines with two-hand controls, emergency stops, and live monitoring. Our staff undergoes regular training and we follow ISO safety management systems. Clients benefit from consistent output without the risk of unplanned downtime from operator injuries or machine faults.

LOOP_END

LOOP_START

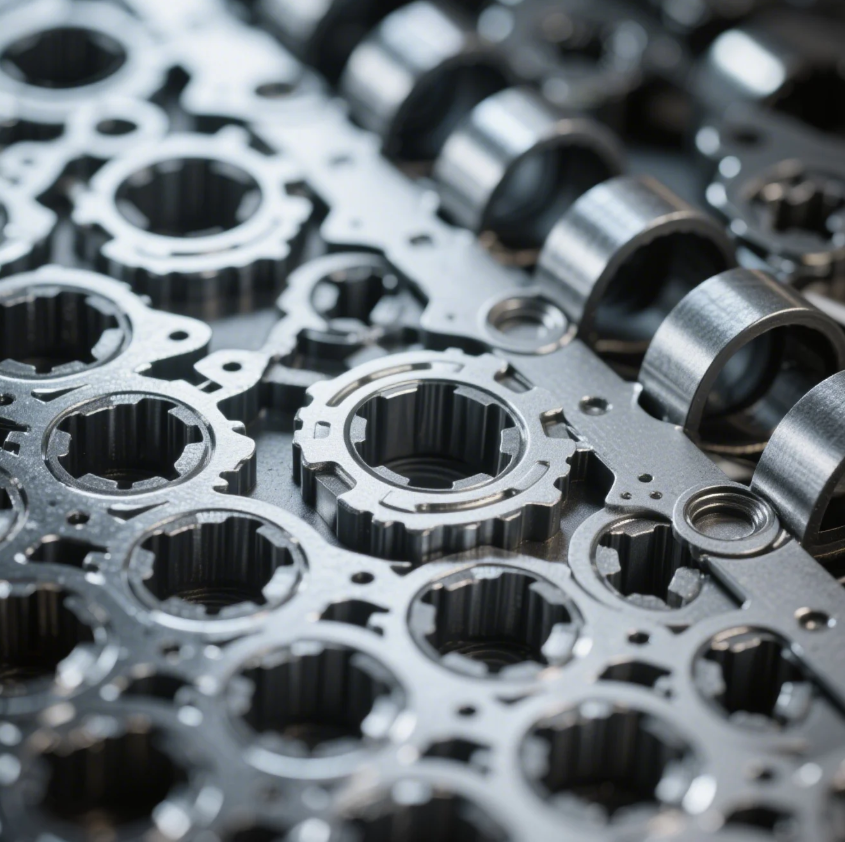

What are the defects of stamping?

Poorly managed stamping can lead to defective parts that cause delays or rejections.

Stamping defects include wrinkles, cracks, springback, and burrs—often caused by incorrect die setup or poor material.

Typical stamping defects

| Defect | Cause | Impact |

|---|---|---|

| Wrinkling | Excess material, poor blank holder force | Aesthetic flaws, assembly issues |

| Cracking | Over-stretching or poor metal ductility | Structural failure risk |

| Springback | Metal returns to shape after forming | Fitment issues |

| Burrs | Dull dies or excessive clearance | Sharp edges, additional deburring required |

Prime’s prevention strategy

We use CNC-machined dies, perform incoming material inspections, and adjust our press parameters based on part geometry. For one EU client in the HVAC sector, our customized die design eliminated cracking in their steel brackets, boosting yield from 91% to 99.3%.

LOOP_END

LOOP_START

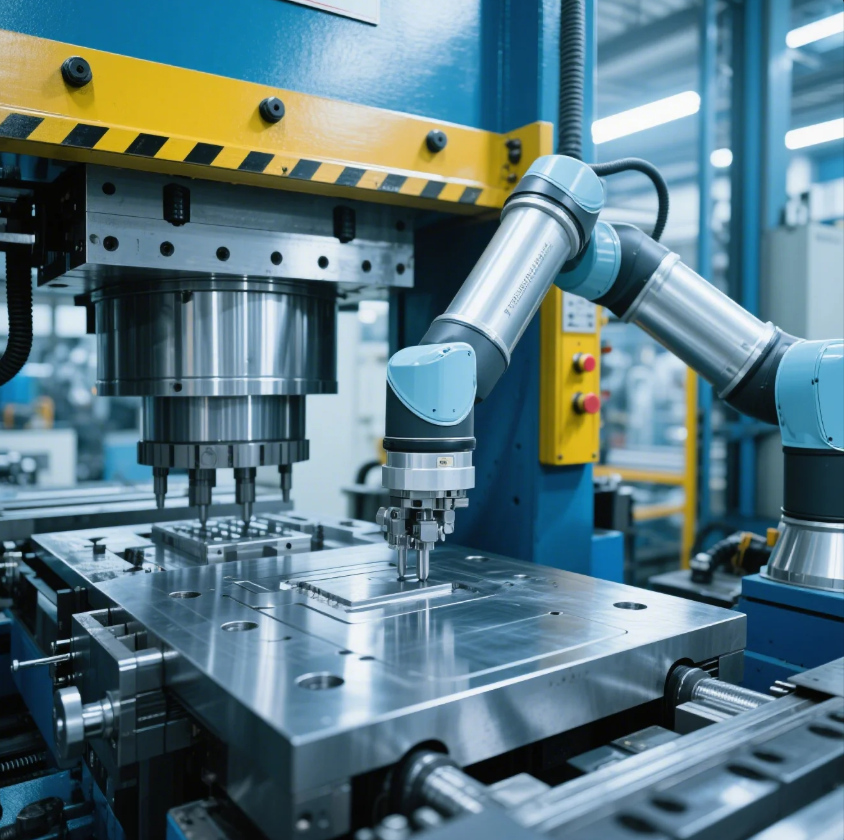

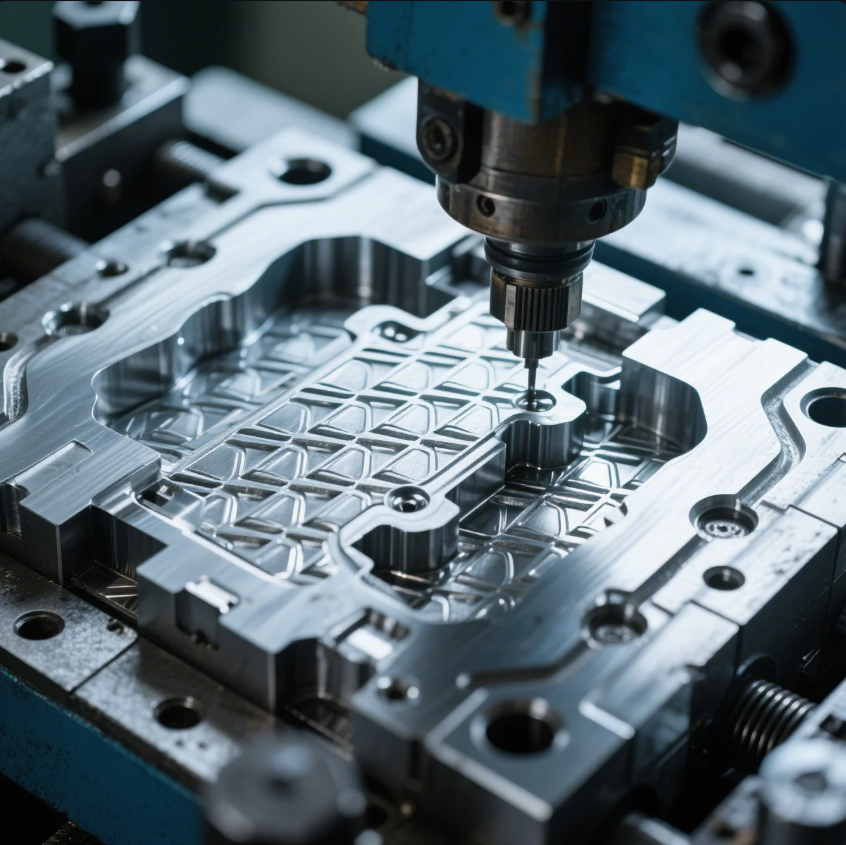

How does stamping process work?

To solve stamping problems, it’s important to first understand how it works.

The stamping process uses a press and matched dies to shape, cut, and form sheet metal into a final part.

Basic stamping process

| Step | Description |

|---|---|

| Material Feeding | Coil or blank is fed into the press |

| Die Setup | Punch and die close to form or cut the metal |

| Stroke Execution | Press ram moves vertically to complete the shape |

| Part Ejection | Finished piece is pushed or pulled from the die |

Where problems can begin

Issues usually come from tool misalignment, incorrect lubrication, or operator error. At Prime, we prevent this by combining real-time sensor feedback and automated die alignment systems—helping clients maintain high part consistency across large orders.

LOOP_END

LOOP_START

What is the problem with metal stamping?

Some manufacturers rely on stamping without fully addressing its design and volume limitations.

Problems with metal stamping include high initial tooling cost, limited flexibility, and tight material specs.

Common challenges in stamping

| Issue | Description |

|---|---|

| High Tooling Cost | Die design and production are expensive upfront |

| Low Design Flexibility | Re-tooling is needed for design changes |

| Material Constraints | Not suitable for brittle or very thick materials |

| Production Downtime | Die maintenance or replacement slows production |

How Prime helps solve these issues

We offer modular die setups, reducing retooling costs for product iterations. Clients can also benefit from free DFM (Design for Manufacturability) consulting before tooling. For one North American lighting client, this saved over $18,000 in tooling revisions during the initial run.

LOOP_END

Conclusion

Stamping has limits—defects, hazards, and high tooling costs—but with proper control, it delivers fast, accurate results.

Looking to reduce stamping risks and defects? Contact Prime today for free expert advice, precision tooling, and ISO-certified production lines that keep your project on time and under budget.