What Are the Engineering Applications of Plastics and Polymers?

What are the engineering applications of plastics and polymers? This question has become central to modern manufacturing, as these materials now power everything from autonomous robotics to aerospace insulation.

Engineering plastics and polymers are widely used in mechanical, structural, electrical, and thermal applications due to their unique balance of strength, weight, and processability.

In this article, we’ll walk through what the engineering applications of plastics and polymers look like in real-world scenarios—and how they’re helping global industries move faster, safer, and more sustainably.

What Are the Engineering Applications of Plastic?

When people ask “What are the engineering applications of plastics and polymers?”, they often mean engineering-grade plastics used in demanding environments.

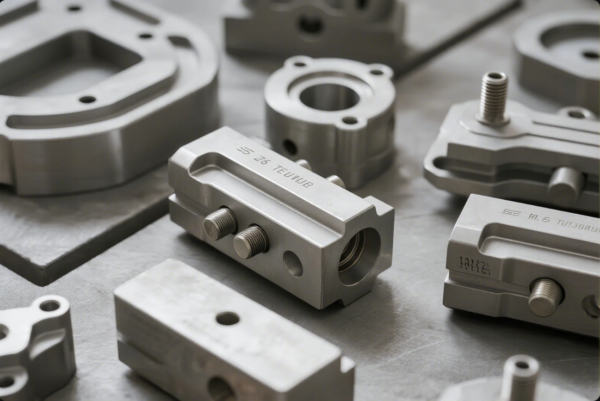

Plastics like ABS, POM, PC, PA, and PEEK are essential for manufacturing mechanical components that must endure stress, heat, and wear—such as gears, brackets, switch housings, and enclosures.

| — | ||||||

|---|---|---|---|---|---|---|

| Automotive | ABS, PA6 | Cable holders, dashboards, clips | ||||

| Industrial | POM, PTFE | Gears, bushings, alignment tools | ||||

| Aerospace | PEI, PAI | Panel structures, fluid seals | ||||

| Electronics | PC, ABS | Enclosures, display bezels, mounts |

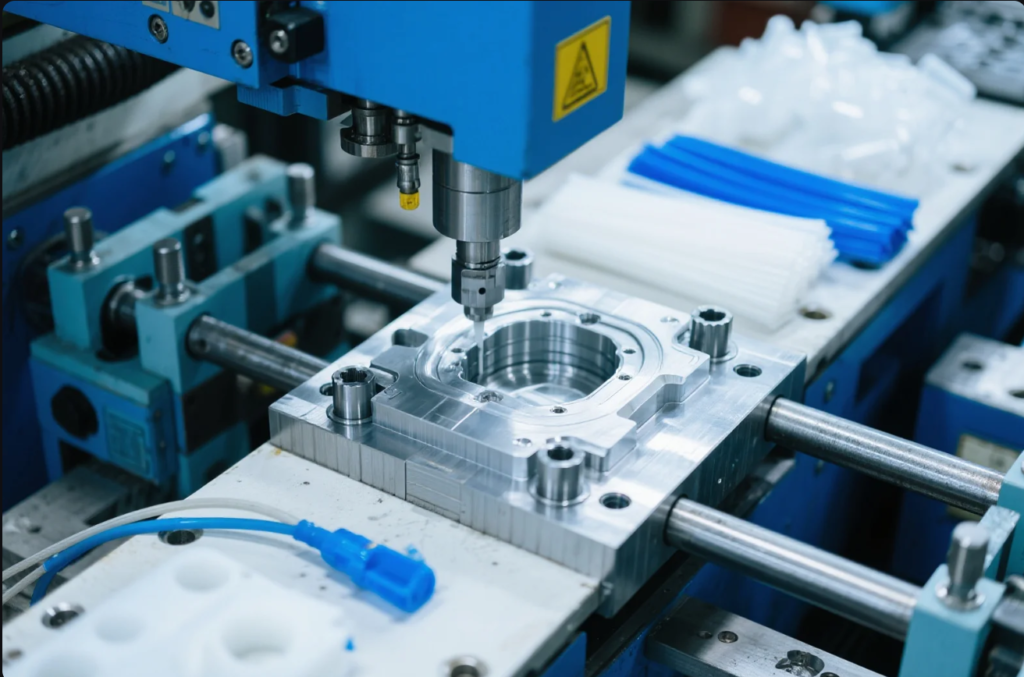

At Prime, we specialize in custom plastic components for engineering use, from tight-tolerance CNC bushings to shock-resistant cable guides—all produced under ISO-certified systems.

What Are the Engineering Applications of Polymers?

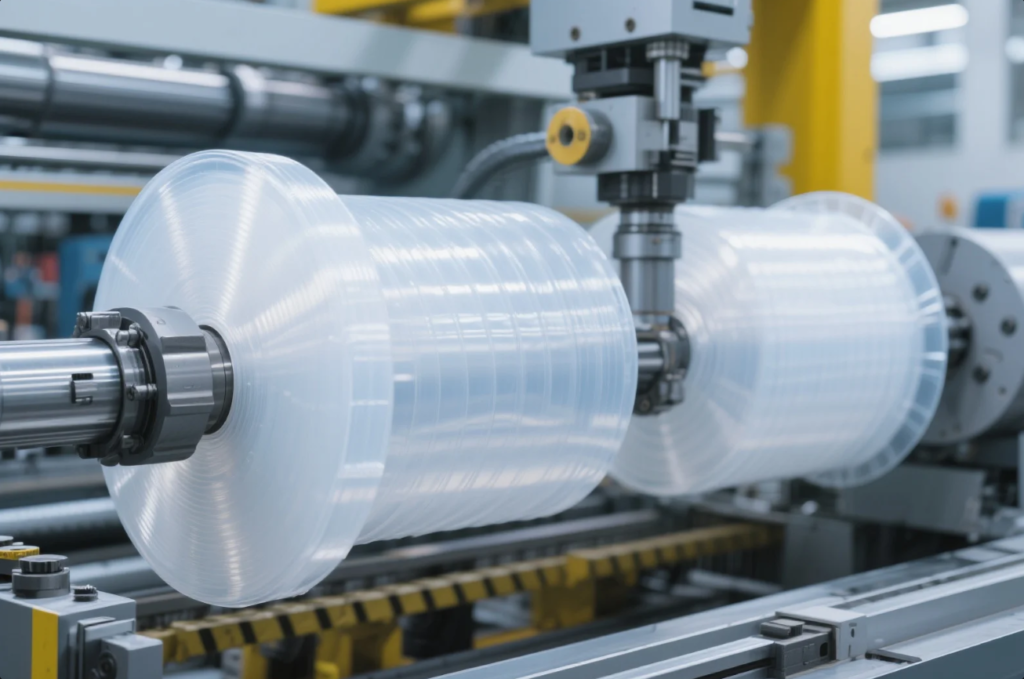

If you\’re exploring “What are the engineering applications of plastics and polymers?”, polymers represent the broader family, including both thermoplastics and thermosets.

Polymers are used in everything from composite aircraft skins to chemical seals and bio-safe implants. Their mechanical behavior under heat, pressure, and fatigue make them ideal for high-stress systems.

| — | ||||||

|---|---|---|---|---|---|---|

| Structural Design | Sandwich cores, beams | CFRP, PU, epoxy | ||||

| Biomedical Engineering | Tubes, implants, devices | PLA, Silicone | ||||

| Electrical Systems | PCB substrates, cables | PVC, PI, PET | ||||

| Thermal Control | Heat shields, spacers | PEEK, PPS |

Our engineers at Prime recently supported a solar firm by developing high-temp polymer panels that resist UV degradation and maintain rigidity in +60°C desert environments.

How Are Plastics Used in Engineering?

Understanding how plastics work in engineering design is key to answering “What are the engineering applications of plastics and polymers?”

Engineering plastics are used as metal alternatives in moving parts, insulating layers in electronics, and pressure-bearing components in pumps or fixtures.

Top 5 Engineering Use Cases

- Lightweight mechanical parts in automotive and aerospace.

- Electrical insulation in control cabinets, battery packs.

- Corrosion-resistant parts in marine and chemical equipment.

- Impact-resistant housings for power tools, sensors.

- Wear-resistant gears and spacers in robotics and conveyor lines.

With 10 production lines, Prime delivers plastic engineering parts for customers in the U.S., Germany, UAE, and more.

What Is Plastic and Polymer Engineering?

This academic and industrial field answers the question: “What are the engineering applications of plastics and polymers from a material science perspective?”

Plastic and polymer engineering involves material selection, process optimization, performance testing, and product development using synthetic materials.

Key Components of the Discipline

- Design & Simulation: CAD, flow analysis, finite element simulation

- Material Testing: Tensile, flexural, fatigue, UV stability

- Processing: Injection molding, extrusion, overmolding

- Sustainability: Bio-based plastics, recyclability, lifecycle assessment

More technical resources can be found at The Society of Plastics Engineers (SPE)—a global hub for polymer innovation.

FAQs

Q: What are the engineering applications of plastics and polymers in electronics?A: Insulators, housing units, EMI shields, and cable management—all made from PC, PPS, and PA6.

Q: Why are plastics replacing metals in mechanical design?A: For parts that need to be light, corrosion-resistant, and easy to shape—like gears, clips, and pumps.

Q: What polymer is best for high-heat engineering environments?A: PEEK and PEI are excellent for sustained temperatures over 200°C.

Q: Is plastic and polymer engineering relevant to green energy?A: Yes. Polymers are used in battery cases, solar mounting hardware, and wind turbine components.

Q: How does Prime support engineering-grade polymer sourcing?A: We provide full-service design, tooling, molding, and logistics for global OEMs needing performance plastic solutions.

Conclusion

So, what are the engineering applications of plastics and polymers? From medical implants to aerospace housings, they’re at the core of innovation.

Shandong Prime International Trade Co., Ltd. delivers engineering-grade plastic parts with ISO-certified quality, fast turnaround, and expert technical support.

📩 Contact: [email protected]🌐 Website: https://primecustomparts.com

Work with a team that understands engineering plastics—inside and out.