What are the steps of the drawing process?

The drawing process is a key technique used in metalworking to create deep, complex shapes from flat sheets of metal. This process involves pulling the metal through a die, which forms the desired shape, often creating parts like cans, containers, and other hollow components. The drawing process can be broken down into several steps, each of which plays an essential role in ensuring the finished product meets the required standards. In this article, we’ll explore the steps involved in the drawing process, including the five key steps and variations like the four-step process.

Snippet paragraph: The drawing process involves several steps to shape metal into deep, intricate parts. Understanding each step ensures the production of high-quality results.

Transition paragraph: Let’s break down the drawing process step by step, and explore the different variations of this technique.

What are the 5 steps of drawing?

The drawing process generally involves a series of steps that transform flat metal sheets into three-dimensional parts. In a typical 5-step drawing process, the following stages are essential:

- Blanking: Cutting the metal sheet into the required shape or blank.

- Drawing: The metal is pulled through a die to begin forming the desired shape.

- Redrawing (if necessary): If the initial draw does not create the required depth, the part may be drawn again for further refinement.

- Trimming: Excess material is removed to ensure the part fits the exact specifications.

- Finishing: The part is cleaned, coated, and prepared for final use.

Snippet paragraph: The 5 steps of drawing include blanking, drawing, redrawing, trimming, and finishing to create deep, high-quality metal parts.

Dive Deeper:

Here’s a detailed look at the 5 steps of the drawing process:

-

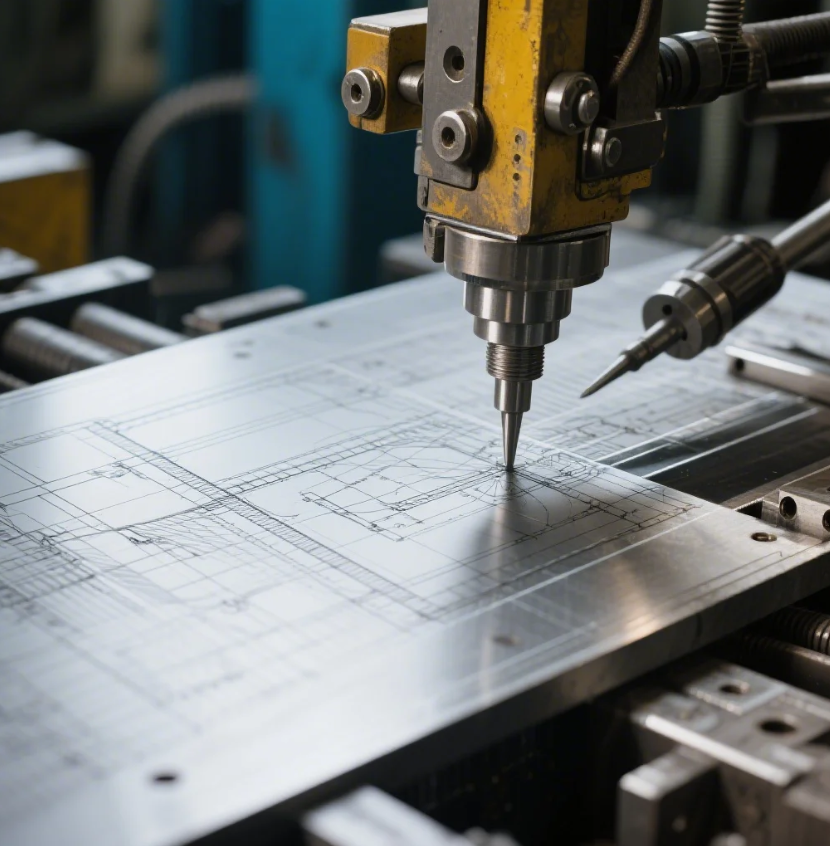

Blanking:

The first step in the drawing process is blanking, where the raw metal sheet is cut into a blank, which is the starting point for the entire operation. The blank’s dimensions are crucial because any errors here can affect the rest of the process. The blank’s thickness and size are carefully measured to ensure it fits the die, allowing it to be drawn effectively. -

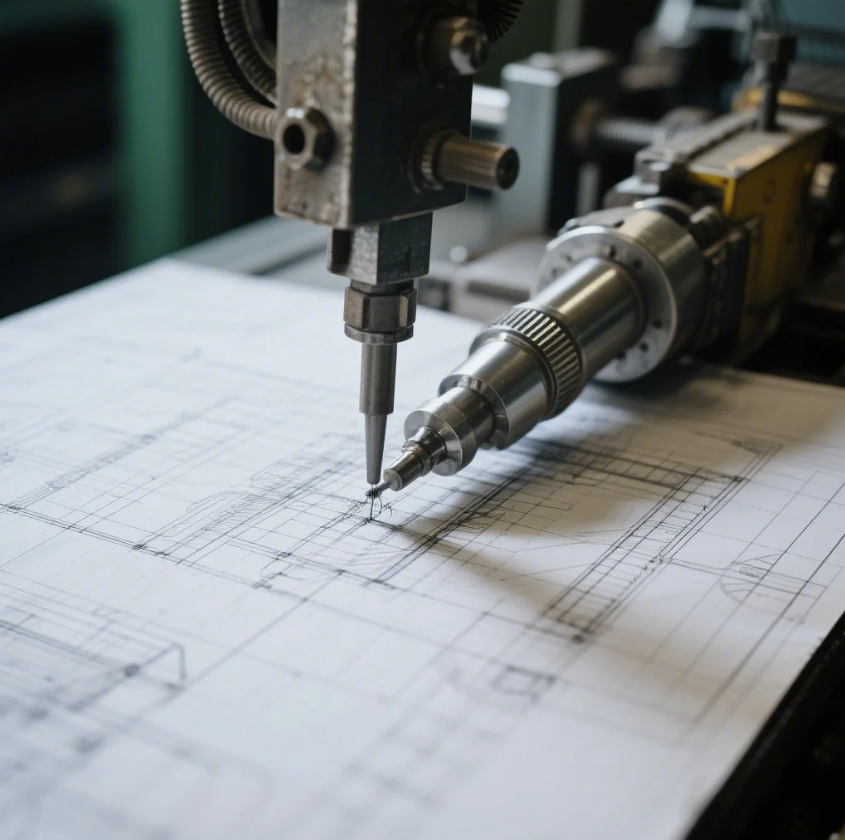

Drawing:

Once the blank is prepared, the drawing process begins. The blank is placed into a die, and a punch press pulls the material through the mold, stretching the metal to form a deeper part. The drawing process is responsible for shaping the material into complex shapes like cups, cans, or other containers. It requires careful control to prevent material defects, such as thinning or wrinkling. -

Redrawing (if necessary):

In some cases, the initial drawing doesn’t achieve the required depth or shape. Redrawing allows the metal to be pulled through the die again to increase the depth or improve the shape. This step can be performed multiple times, depending on the complexity of the part being created. Redrawing is essential for deep-drawn parts that require multiple stages of shaping. -

Trimming:

Once the desired shape is achieved, the next step is trimming. During trimming, any excess material is removed from the part, typically around the edges or areas that were not properly formed during the drawing. This ensures the part fits precisely and is ready for the finishing process. -

Finishing:

The final step in the drawing process involves cleaning, coating, and preparing the part for its intended use. This could include removing any remaining sharp edges, adding protective coatings to prevent corrosion, or polishing the surface to improve its appearance. The finishing process ensures that the part is both functional and aesthetically appealing.

What are the processes of drawing?

The drawing process involves several techniques and stages to create deep shapes from flat metal. While the basic concept remains the same—pulling metal through a die—different variations exist to accommodate the complexity of the part being produced. Here are the general processes involved in drawing:

- Shallow Drawing: This involves drawing the metal through the die to form a relatively shallow part. It’s used for parts that don’t require significant depth.

- Deep Drawing: This is a more complex process used to create deep, intricate parts, such as beverage cans or automotive parts. Multiple stages may be required to achieve the desired depth.

- Redrawing: After the initial draw, if the part is not deep enough, redrawing pulls the material through the die again to achieve the correct depth.

- Stretching: In some cases, the metal is stretched to increase its formability without thinning. This is especially useful for parts that require more flexibility or complex shapes.

Snippet paragraph: Drawing processes include shallow, deep, and redrawing methods to shape metal, depending on the part’s complexity and depth requirements.

Dive Deeper:

Each drawing process is tailored to the specific needs of the part being produced:

- Shallow Drawing: This technique is used for parts that require only a slight depth. For example, shallow dishes or trays are created using this process. The blank is drawn through a mold in a single step without much deformation.

- Deep Drawing: Deep drawing creates parts with significant depth and is commonly used for parts like cans, containers, or automotive components. The metal is pulled through the die multiple times, gradually increasing the depth.

- Redrawing: In deep-drawn parts, redrawing helps refine the shape and achieve the necessary depth. The material is passed through the die again, further shaping it.

- Stretching: Stretching is used to make the material more pliable before drawing. It’s often applied to metal that requires additional flexibility to form complex shapes without thinning.

What is the 4-step drawing process?

The 4-step drawing process is a simplified version of the drawing process, typically used for creating less complex parts. It focuses on achieving the desired depth or shape using only four essential steps. These steps include blank preparation, drawing, redrawing (if necessary), and finishing. This process is commonly used for parts that don’t require the extreme precision or complexity of deeper drawing methods.

Snippet paragraph: The 4-step drawing process simplifies the steps involved in shaping metal, focusing on blank preparation, drawing, redrawing, and finishing.

Dive Deeper:

The 4-step drawing process is often used for parts that require basic shaping. Here’s how it works:

- Blank Preparation: A blank is cut from the metal sheet, sized for the drawing process.

- Drawing: The blank is pulled through the die to create the desired part.

- Redrawing (if necessary): If the part needs more depth, the drawing process is repeated.

- Finishing: The part is finished by trimming and cleaning.

This simplified process can be efficient for basic parts, as fewer stages are required, and it’s typically faster than deep-drawing methods.

What is drawing step by step?

Drawing step by step refers to the sequential process of pulling a metal blank through a die to form a desired shape. Each step in the process is designed to shape the metal progressively, with checks and balances to ensure that the part is formed correctly at each stage. Drawing step by step involves the following key actions:

- Blanking: Cutting the raw material into the right size.

- Drawing: Pulling the metal through the die to form the part.

- Redrawing: Refining the shape by passing the metal through the die again.

- Finishing: Trimming, cleaning, and preparing the part for final use.

Snippet paragraph: Drawing step by step involves sequential stages of blanking, drawing, redrawing, and finishing, ensuring a high-quality result.

Dive Deeper:

In drawing step by step, each stage serves a distinct purpose. Blanking ensures the material is the right size, drawing forms the initial shape, redrawing refines the shape, and finishing ensures the part meets all specifications. The process is often used for complex parts that require precise dimensions and depth, such as automotive components or containers.

Conclusion

The drawing process is essential for creating deep, intricate parts from flat metal sheets. Understanding each step—blanking, drawing, redrawing, and finishing—helps ensure that the final product meets the required quality and specifications. Whether you’re dealing with a simple part or a complex deep-drawn component, Prime offers expert services in metal drawing to meet your needs. Contact us today for more information and to request a customized quote!