What are the steps of the drawing process?

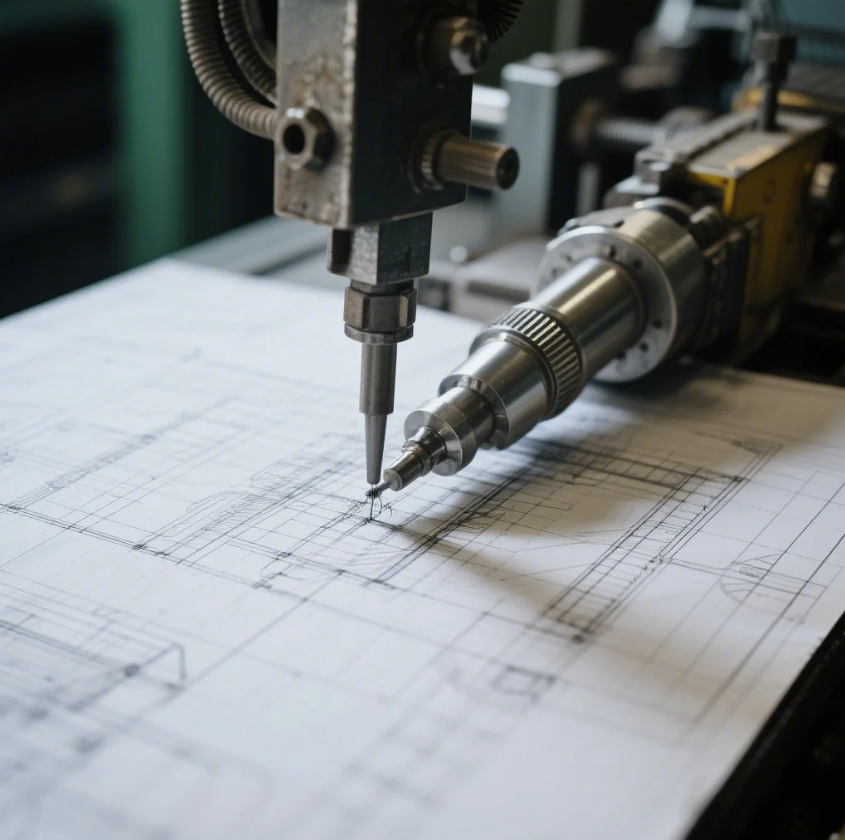

The drawing process is a widely used technique in metalworking that transforms flat metal sheets into deep, intricate shapes. This process involves stretching the metal by pulling it through a die, creating parts such as containers, automotive components, and other deep-drawn products. In this article, we’ll break down the steps of the drawing process, explain different variations of it, and highlight key details to ensure high-quality results.

Snippet paragraph: The drawing process involves several steps that shape metal into deep, complex parts. Each step is critical to achieving the final design and quality.

Transition paragraph: Let’s dive deeper into the steps of the drawing process, from blanking to finishing, and explore the variations of this technique.

What are the 5 steps of drawing?

The drawing process typically involves five essential steps to create deep and complex shapes from flat metal sheets. These steps ensure that the metal is properly formed, without defects like thinning, cracking, or wrinkling. Here are the five key steps of the drawing process:

- Blanking: The metal sheet is cut into the appropriate shape and size, known as the blank, which will be used in the drawing process.

- Drawing: The blank is pulled through a die to begin forming the desired shape, such as a cup or can.

- Redrawing (if needed): If the desired depth or shape is not achieved in the initial drawing, the part is drawn again for refinement.

- Trimming: Excess material is removed to create the correct dimensions and clean edges.

- Finishing: The part is cleaned, coated, and treated to ensure it meets both functional and aesthetic requirements.

Snippet paragraph: The five key steps of drawing include blanking, drawing, redrawing (if necessary), trimming, and finishing to create high-quality deep-drawn parts.

Dive Deeper:

Let’s explore each of these steps in more detail:

-

Blanking:

In the blanking stage, the raw metal sheet is cut into a blank that is sized appropriately for the drawing process. The size and thickness of the blank are critical because if they’re incorrect, it can affect the entire drawing operation. The blank is usually round, though other shapes can be used depending on the part being created. -

Drawing:

The drawing step is where the actual forming begins. The metal blank is placed in a die and pulled through by a punch press, stretching the metal and shaping it into a desired part, such as a cup, can, or another deep form. This process requires precision to prevent defects like wrinkles, tearing, or thinning of the material. -

Redrawing (if needed):

In deep-drawing applications, redrawing is often necessary. This involves pulling the metal through the die again to achieve greater depth. Redrawing helps refine the shape, ensuring that the part meets the required depth and uniformity. The material is stretched again, and care must be taken to avoid overstretching, which could cause the metal to become weak or deformed. -

Trimming:

Once the part has been drawn to the desired depth and shape, excess material is removed through trimming. This ensures the part has smooth edges and the correct dimensions. The trimming operation removes any burrs or extra material from the edges, creating a clean, finished part that is ready for the final stage. -

Finishing:

The final step is finishing, which includes cleaning the part, removing any oils or debris, and applying coatings for surface protection. Depending on the part’s intended use, finishing may also involve polishing, painting, or applying protective coatings to improve corrosion resistance, durability, and appearance.

What are the processes of drawing?

The drawing process involves several variations depending on the complexity of the part and the depth required. The key processes of drawing are as follows:

- Shallow Drawing: This technique is used to create parts with shallow depths, such as trays or shallow dishes. The metal is pulled through a die to form a part that does not require significant depth.

- Deep Drawing: Deep drawing is used to create parts with significant depth, such as cans or automotive body panels. The metal is pulled through the die multiple times to achieve the desired depth.

- Redrawing: After the initial drawing, redrawing can be performed to further refine the depth or shape of the part.

- Stretch Forming: In some cases, the metal is stretched before being drawn to make it more pliable, allowing for more intricate shapes.

Snippet paragraph: Drawing processes include shallow drawing, deep drawing, redrawing, and stretch forming, each tailored to produce different depths and shapes.

Dive Deeper:

Here’s a breakdown of each process:

-

Shallow Drawing: Shallow drawing is used to create parts that require only a small amount of depth. It’s often used for creating parts like trays, shallow bowls, or containers that don’t need to be deeply shaped. The process involves pulling the metal through a die in a single step without significant stretching.

-

Deep Drawing: This is used for creating parts with substantial depth, such as beverage cans or containers. Deep drawing often requires multiple stages to achieve the desired depth. The metal is pulled through the die several times, with each pass increasing the part’s depth while maintaining a uniform thickness.

-

Redrawing: Redrawing is used to refine the shape and depth of parts created through deep drawing. By pulling the part through the die again, the material is further stretched and shaped. Redrawing ensures that the final part meets the required dimensions and depth.

-

Stretch Forming: Stretch forming is used to stretch the metal before it’s drawn, making it more pliable. This method is often used for parts that require complex shapes, as it allows the material to be stretched evenly without thinning out too much.

What is the 4-step drawing process?

The 4-step drawing process is a simplified version of the traditional drawing process, often used for parts that do not require complex shapes or deep depths. This process includes four basic stages:

- Blank Preparation: The metal is cut into the required size and shape for the drawing process.

- Drawing: The metal is pulled through the die to form the part.

- Redrawing (if necessary): If the part is not deep enough, it’s drawn again for further shaping.

- Finishing: The part is cleaned, trimmed, and prepared for final use.

Snippet paragraph: The 4-step drawing process involves blank preparation, drawing, redrawing, and finishing to create simpler parts with less complexity.

Dive Deeper:

The 4-step drawing process is typically used for parts that are relatively simple and don’t require multiple stages of drawing. It is faster and more cost-effective compared to deep drawing, making it ideal for parts that have shallow depths or less intricate shapes. The process is often used for creating parts like small containers, trays, or shallow dishes.

What is drawing step by step?

Drawing step by step refers to the sequential process of shaping a metal blank into a finished part through a series of controlled steps. This process is essential for achieving deep, precise shapes from flat metal sheets. The typical steps in drawing step by step include:

- Blank Preparation: The metal sheet is cut into the correct size and shape for the drawing process.

- Drawing: The blank is pulled through a die to form the desired shape.

- Redrawing (if needed): If the initial drawing is not deep enough, the part is redrawn.

- Finishing: The part is trimmed and cleaned for final use.

Snippet paragraph: Drawing step by step involves blanking, drawing, redrawing (if necessary), and finishing to produce high-quality metal parts with precision.

Dive Deeper:

Drawing step by step ensures that each stage of the drawing process is carefully controlled to achieve the best possible result. By following this method, manufacturers can ensure the final product meets dimensional accuracy and surface quality standards. The step-by-step approach also helps prevent defects like thinning or cracking, especially in deep-drawn parts.

Conclusion

The drawing process is an essential part of metalworking, enabling manufacturers to create deep and complex parts from flat metal sheets. Understanding the steps of drawing, from blanking to finishing, is crucial to producing high-quality parts. Whether you’re using the 5-step process, the 4-step process, or drawing step by step, Prime offers expert drawing services to meet your needs. Contact us today to learn more and get a customized quote!