What are the three basic types of fasteners?

Fasteners are essential components used to join materials together in construction, manufacturing, and various other industries. While there are many types of fasteners, they generally fall into three basic categories. Understanding these fundamental types of fasteners is crucial when selecting the right one for your project.

Snippet paragraph: The three basic types of fasteners—mechanical, adhesive, and permanent—serve different purposes in joining materials. Let’s break them down.

In this article, we’ll explore the three basic types of fasteners, their applications, and other important factors to consider when choosing fasteners for your projects.

What are the three types of fasteners?

The three basic types of fasteners are mechanical fasteners, adhesive fasteners, and permanent fasteners. Each of these categories has different applications depending on the required strength, ease of removal, and the materials being joined.

Snippet paragraph: Fasteners are categorized into mechanical, adhesive, and permanent types, each designed for specific applications and material requirements.

1. Mechanical Fasteners:

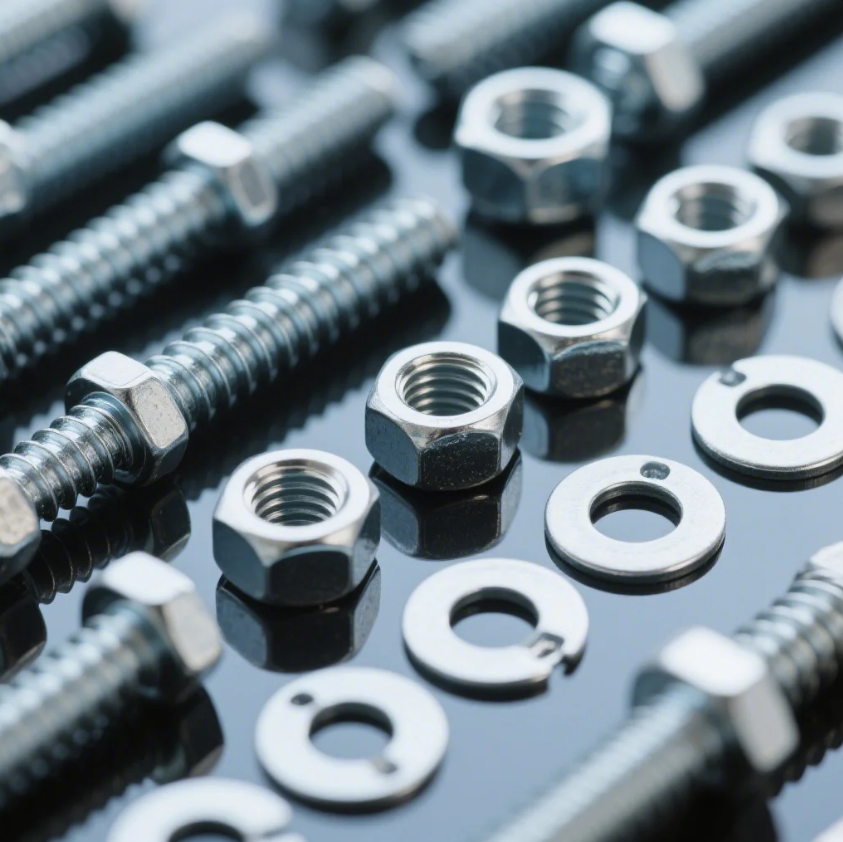

Mechanical fasteners are the most commonly used fasteners and include screws, bolts, nuts, and washers. These fasteners rely on the mechanical properties of the materials to hold things together. They are often used in situations where disassembly or adjustment may be required in the future.

- Common Examples: Screws, bolts, nuts, washers, clips, and pins.

- Applications: Used in construction, automotive, electronics, and furniture assembly. These fasteners can be tightened or loosened with the proper tools, making them versatile for different projects.

2. Adhesive Fasteners:

Adhesive fasteners use bonding agents to hold materials together. They provide an alternative to mechanical fasteners and are ideal for applications where traditional fasteners may not be suitable or where a clean, seamless appearance is desired.

- Common Examples: Glues, tapes, and bonding agents.

- Applications: Used in the automotive, electronics, and packaging industries. Adhesive fasteners are ideal for joining non-metallic materials such as plastics, wood, and composites.

3. Permanent Fasteners:

Permanent fasteners create a lasting connection between materials, and once installed, they cannot be easily removed. They are typically used when a long-lasting or permanent bond is required.

- Common Examples: Rivets, welds, and certain types of clamps.

- Applications: Used in structural applications like bridges, buildings, and aircraft, where a permanent bond is necessary for safety and performance.

What are the basics of fasteners?

Fasteners are components that play a crucial role in holding materials together, but understanding the basic features and function of these devices is essential for selecting the right one for your needs.

Snippet paragraph: The basics of fasteners involve understanding their purpose, types, and the factors that influence their selection, including material, strength, and ease of use.

Key Considerations in Fastener Selection:

- Material: The material of the fastener affects its strength, corrosion resistance, and suitability for specific applications. For example, stainless steel is commonly used in environments where rust resistance is critical.

- Size: The size of the fastener should match the dimensions of the materials being joined. Fasteners come in various lengths, diameters, and thread types.

- Strength: The strength of the fastener determines how much load it can bear before it fails. High-strength fasteners are required for heavy-duty applications.

- Ease of Removal: Mechanical fasteners are easy to remove, while permanent fasteners like rivets require cutting or drilling to remove.

- Environmental Factors: Factors like temperature, exposure to chemicals, and moisture can influence the type of fastener you choose. Corrosion-resistant fasteners are often necessary for outdoor or marine applications.

Common Fastening Mechanisms:

- Threads: Screws, bolts, and nuts rely on threads to create a secure connection.

- Interference Fit: Some fasteners use an interference fit, where the fastener and the hole are slightly mismatched to create a tight fit.

- Snap-Fit: Snap-fit fasteners rely on flexible components that snap into place, often used in plastic assemblies.

What are the three methods of fastening?

There are three primary methods of fastening materials: threaded fastening, friction fastening, and adhesive fastening. Each method has its advantages and is chosen based on the specific needs of the project.

Snippet paragraph: Fastening methods include threaded fastening (screws and bolts), friction fastening (clips and clamps), and adhesive fastening (glues and bonding agents).

1. Threaded Fastening:

This is one of the most common and versatile fastening methods. It involves using screws, bolts, and nuts, where threads on the fastener mesh with threads in the hole to create a strong and adjustable connection.

- Advantages: Provides a secure, adjustable connection. Easy to assemble and disassemble.

- Applications: Used in construction, automotive, and machinery where parts need to be frequently assembled and disassembled.

2. Friction Fastening:

Friction fasteners rely on pressure to hold parts together. Common examples include clips, clamps, and pins. These fasteners do not rely on threads and are used when a temporary or removable connection is required.

- Advantages: Quick to install and remove. Ideal for applications where frequent adjustments or removals are necessary.

- Applications: Used in automotive, electrical, and consumer goods where parts need to be held in place securely but still be easy to remove.

3. Adhesive Fastening:

Adhesive fastening uses bonding agents, such as glue or tape, to hold parts together. This method is ideal for joining non-metallic materials or for when a smooth appearance is needed without visible fasteners.

- Advantages: No visible fasteners. Ideal for bonding dissimilar materials.

- Applications: Common in packaging, electronics, and construction when a seamless finish is required.

What are the three basic types of threads used on fasteners?

Threads are an essential feature of many fasteners, including screws and bolts. The type of thread used determines how the fastener will perform in terms of strength, ease of installation, and the types of materials it can secure.

Snippet paragraph: The three basic types of threads used on fasteners are unified threads, metric threads, and pipe threads. Each has unique properties for different applications.

1. Unified Threads (UNC/UNF):

Unified threads are commonly used in the United States and are used for screws and bolts in a variety of applications. They include both coarse (UNC) and fine (UNF) threads, which are suited for different materials and applications.

- Coarse Threads (UNC): Designed for softer materials and provide a more secure connection under vibration.

- Fine Threads (UNF): Provide more precise adjustments and are used in applications that require greater strength and resistance to shear.

2. Metric Threads:

Metric threads are the standard in many countries outside of the U.S., including Europe. They are defined by the distance between threads in millimeters (e.g., M6 x 1). Metric threads come in both coarse and fine variations, similar to unified threads.

- Coarse Threads (M): Common for general use and are easier to thread into materials.

- Fine Threads (MF): Provide a stronger hold and are used in high-precision applications.

3. Pipe Threads:

Pipe threads are specialized threads used for connecting pipes and pipe fittings. They are designed to seal against leaks and are often tapered to create a tight, leak-proof connection.

- Common Types: NPT (National Pipe Thread) and BSPT (British Standard Pipe Thread) are the two most common types of pipe threads used for piping applications.

| Thread Type | Common Uses | Features |

|---|---|---|

| Unified Threads | General fasteners (screws, bolts) | Coarse for softer materials, fine for stronger holds |

| Metric Threads | European standard, machinery | Precise measurements in millimeters |

| Pipe Threads | Plumbing and piping applications | Tapered design for leak prevention |

Conclusion

Understanding the basic types of fasteners—mechanical, adhesive, and permanent—is essential for choosing the right fastening solution for your project. Whether you are working with screws, bolts, rivets, or adhesives, the type of fastener you select will depend on the materials, the required strength, and the ease of assembly and disassembly. Additionally, the three primary types of threads—unified, metric, and pipe threads—further help refine the selection process for your fastening needs.

By selecting the appropriate type of fastener, you can ensure a secure, long-lasting connection for your projects, whether in construction, manufacturing, or everyday applications.