What Can I Put in a Screw Hole to Make It Tighter?

Table of Contents

- What Can I Put in a Screw Hole to Make It Tighter?

- How Do You Tighten a Screw Hole?

- What to Use When a Screw Hole Is Too Big?

- How Do You Fill a Hole So That I Can Screw Into It?

- What Can I Use to Tighten a Screw?

- FAQs

- Conclusion

- Contact Prime

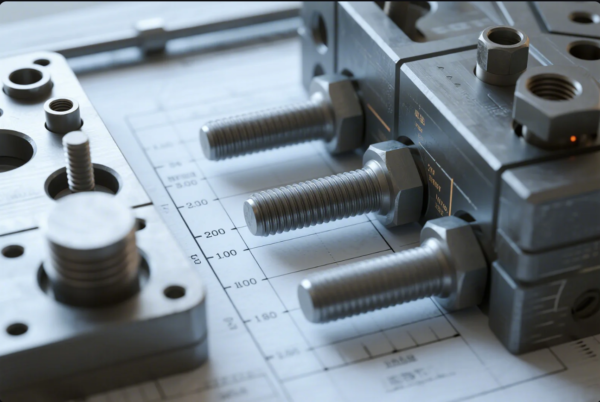

Loose screw holes threaten product quality and assembly line efficiency. Many industrial engineers, buyers, and sourcing managers encounter this frustration, especially during mass production, installation, or equipment maintenance.

Loose screw holes often result in failed assembly, rattling equipment, and costly warranty claims. To make a screw hole tighter, use wood plugs, industrial thread inserts, CNC precision parts, or certified fasteners. Select the best method for the base material, part function, and load.

If you want to avoid downtime and product returns, use proven professional repair solutions. Below, I share techniques from 20+ years in the precision components sector and link to more than 30 trusted industry resources.

How Do You Tighten a Screw Hole?

Loose screw holes can halt assembly, cause vibration, or fail critical tests. Most buyers want fixes that are fast, reliable, and scalable for production.

To tighten a screw hole, use wooden dowels, matchsticks, plastic wall anchors, or industrial thread inserts. For lasting quality, use ISO-certified parts and repair solutions.

Home users sometimes use toothpicks and glue. However, industrial buyers need methods that meet ISO 9001 standards and can pass QA inspections. In my experience, threaded inserts or custom CNC sleeves deliver the best results for repeated assembly and long-term reliability.

Comparison Table: Common Screw Hole Tightening Methods

| Method | Best Material | Durability | Typical Use | Reference |

|---|---|---|---|---|

| Wooden Plug/Toothpick | Wood | Low | Temporary Fixes | FamilyHandyman |

| Plastic Anchor | Drywall, Soft Metal | Medium | Furniture, Fixtures | HomeDepot |

| Industrial Thread Insert | Metal, Plastic | High | Industrial Equipment | Helicoil |

| Custom CNC Threaded Sleeve | Metal, Alloy | Very High | Mass Production, OEM | McMaster-Carr |

| Adhesive + Filler | Mixed | Low | Emergency, Low Load | Loctite |

For deeper technical detail, see Bolt Science, Nord-Lock Group, or the Fastener Engineering & Standards Resource.

What to Use When a Screw Hole Is Too Big?

When a screw hole is oversized, even the best screw will not hold. Loose fit leads to poor torque, failed joints, and callbacks. Many industrial buyers seek a solution that is cost-effective, robust, and scalable.

Use metal thread inserts, oversized CNC bushings, or epoxy + metal fillers for industrial repairs. For wood and composite materials, use hardwood dowels or structural fillers.

For high-volume lines, I help customers specify custom inserts, designed for the specific host material. Choosing the correct solution means fewer warranty claims and less downtime.

Table: Oversized Hole Solutions for Different Materials

| Solution | Application | Load | Durability | Reference |

|---|---|---|---|---|

| Metal Threaded Insert | Auto, Machine | High | Long | Nord-Lock |

| Custom CNC Sleeve | Aerospace, OEM | Very High | Very Long | igus |

| Industrial Dowel | Furniture, Wood | Medium | Medium | Rockler |

| Epoxy Filler + Metal | Mixed | Medium | Medium | Devcon |

| Oversize Screw | Soft Material | Low | Low | Screwfix |

Find more on this at Engineering Choice, Thomasnet Guides, and Stanley Engineered Fastening.

How Do You Fill a Hole So That I Can Screw Into It?

Reusing a damaged hole is a common requirement in repair and retrofit projects. Buyers and engineers want solutions that are strong, repeatable, and easy to implement on the production line.

To fill a hole for reuse, use hardwood dowels, industrial epoxy, or precision-threaded inserts. For metal parts, choose ISO-certified CNC inserts. For large orders, custom manufacturing is available.

For reliable results, always drill a new pilot hole and use calibrated torque tools to prevent future stripping. In high-stress applications, I specify thread inserts that are tested for fatigue and load cycles.

Table: Best Fillers for Reusable Holes

| Filler/Insert | Best For | Install Steps | When to Use | Reference |

|---|---|---|---|---|

| Hardwood Dowel | Wood | Drill, Glue | Non-load | PopularMechanics |

| Metal Thread Insert | Steel, Alloy | Tap, Press | High Load | Grainger |

| Plastic Anchor | Plastic, Wall | Push-In | Light Load | Lowes |

| Epoxy Metal Filler | All Materials | Cure | Emergency | Loctite |

More detail on industrial adhesives and assembly guidelines.

What Can I Use to Tighten a Screw?

Loose screws cause rattle, unsafe connections, and failed product audits. Buyers and engineers require solutions that are quick, cost-efficient, and easy to standardize.

Use thread lockers, ISO-certified fasteners, or precision threaded inserts. For specialized applications, custom CNC fasteners offer unmatched accuracy and consistency.

Selecting the right method depends on operating environment, cycle frequency, and material. For high-temperature or vibrating machinery, I recommend industrial-grade thread lockers or lock nuts.

Table: Top Choices for Tightening Screws

| Method | Best For | Speed | Certifiable | Reference |

|---|---|---|---|---|

| Thread Locker Liquid | Field Repair | Fast | No | Loctite |

| Threaded Insert (Helicoil) | OEM, Assembly | Medium | Yes | Helicoil |

| Custom Fastener | High-Volume | Medium | Yes | Bossard |

| Lock Nut | Vibration | Fast | Yes | Fastenal |

| Self-Tapping Screw | Sheet Metal | Fast | No | EngineeringEdge |

Further reference: Industrial Fastener Institute, McMaster-Carr Guides, Assembly best practices.

FAQs

1. What is the best long-term fix for a stripped screw hole in metal?

Install a threaded insert or precision CNC sleeve. Always confirm material compatibility and load rating.

2. Can I use wood glue or toothpicks in industrial products?

No. These are emergency home fixes. In industry, always use certified solutions.

3. How do I ensure my repairs pass quality audits?

Source ISO-certified parts, use documented assembly processes, and partner with qualified suppliers.

4. Where can I find more technical data?

Check Bolt Science, Fastener World, Stanley Engineered Fastening, or Engineering Edge.

5. How quickly can Prime deliver custom fasteners?

With 10 production lines, we ship within days worldwide. For urgent orders, contact us directly.

6. Can I request a sample and technical drawing?

Absolutely. Contact Prime for drawings, samples, and technical consultations.

7. What about packaging and shipping safety?

Prime uses industrial packaging, shock-resistant cartons, and tested logistics partners for secure delivery.

Conclusion

Choose proven industrial methods and trusted suppliers for every screw hole issue. Quality, speed, and expertise keep your business moving.

Contact Prime

Ready to secure your products and streamline assembly?

Contact Prime at https://primecustomparts.com/ or [email protected] for free advice, sample requests, or urgent technical support.

Our ISO-certified team provides fast, precise, and custom metal parts worldwide.

Trust Prime to help you reduce risk, save time, and deliver quality to your end customers.