What Do You Mean by Fabrication?

Manufacturers around the world rely on advanced processes to transform raw materials into high-performance parts. One of the most essential of these processes is fabrication.

Fabrication is the industrial practice of converting raw materials—such as metal sheets, tubes, or plates—into functional components through cutting, forming, welding, and assembly.

In this article, we’ll explore the full scope of this process, with real-world examples and its role in engineering.

What Is the Full Meaning of Fabrication?

Fabrication involves more than just shaping parts—it represents the entire lifecycle from concept to functional output.

It includes a wide range of operations that turn raw stock into finished products, using machines like laser cutters, press brakes, and welding stations.

Core Process Components:

- Input materials: Sheet metal, tubes, billets, or rods

- Operations involved: Cutting, bending, welding, grinding, coating

- Final output: Precision-built parts, structures, or assemblies

- Applications: From control cabinets to vehicle frames and beyond

What Is an Example of a Fabrication?

A great example is a custom electrical cabinet used in industrial automation.

The Manufacturing Steps Include:

- Laser cutting the flat panels

- Forming edges using CNC press brakes

- Welding the structure together

- Adding holes and ports for connections

- Applying powder coating for protection

- Final quality inspection and packaging

Other projects include:

- Elevator shafts

- Reinforced enclosures

- Structural mounting systems

- Cleanroom-grade stainless equipment

What Is Fabrication in Engineering?

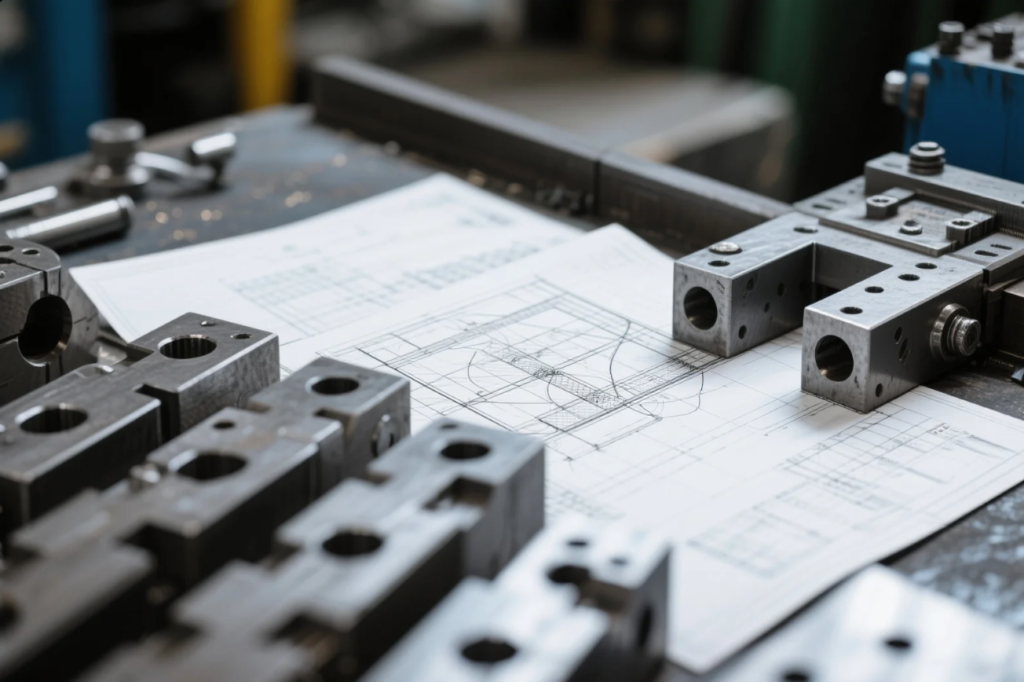

In the context of industrial engineering, fabrication is the execution phase where design drawings become real, measurable products.

What Makes the Process Engineering-Grade?

- Built to tight tolerances (±0.05 mm common)

- Based on CAD/CAM or 3D models

- Material certifications (e.g. ASTM, RoHS, ISO)

- Precise machine programming and process control

- Verification via inspection and test reports

Whether it’s a frame for a robot or a custom bracket for a turbine, the principles remain the same: accuracy, repeatability, and reliability.

How Do You Explain Fabrication?

Here’s a simple explanation:

It’s the process of transforming a design into a tangible component using industrial machinery.

In practice:

“You send us a drawing or concept, and we turn it into a functional metal part—cut, formed, welded, finished, and ready to install.”

Key Processes Summarized:

| Step | Function |

|---|---|

| Cutting | Defines the basic shape |

| Forming | Adds bends, curves, or flanges |

| Welding | Assembles multiple elements |

| Finishing | Improves surface protection or look |

| Inspection | Ensures everything meets the spec |

At Prime, we manage all of these steps under one roof for maximum quality control and delivery speed.

FAQs

Q1: What’s the difference between fabrication and general manufacturing?

Fabrication refers to shaping and assembling raw materials. Manufacturing includes additional steps like molding, machining, or electronic assembly.

Q2: Which industries rely on this process?

Construction, aerospace, automotive, energy, robotics, medical equipment, and heavy industry.

Q3: Do you provide support from prototype to production?

Yes. Prime supports low-volume development and high-volume repeat orders globally.

Q4: What formats do you accept for new projects?

STEP, DXF, PDF, IGES, and even rough sketches.

Q5: What are your material capabilities?

We work with stainless steel, aluminum, carbon steel, brass, copper, and plated or coated sheets.

Contact Prime

Whether you need a single custom bracket or a complete welded enclosure, we can help you move from concept to component with speed and confidence.

📧 Email: [email protected]

🌍 Website: https://primecustomparts.com

At Prime, we bring your parts to life—with precision, performance, and proven results.