What happens to old injection molds?

Have you ever wondered what happens to old injection molds once production ends?

Old molds are either stored, refurbished, recycled, or permanently scrapped depending on condition, tooling value, and customer demand. Managing old injection molds correctly helps reduce waste and control production costs.

Injection molds are the foundation of plastic part manufacturing. But when demand slows or product designs change, companies face an important decision: what should be done with the molds? In this guide, we’ll explain what happens to old injection molds, how long they last, how many times they can be reused, and whether they’re recyclable.

How long do injection molds last?

Understanding the lifespan of a mold is essential to budgeting, planning production, and forecasting maintenance needs.

Injection mold life varies by tool material, design complexity, resin type, and maintenance frequency. Steel molds often last over a million cycles with proper care.

Typical Mold Life Expectancy

| Mold Material | Expected Cycles | Use Case |

|---|---|---|

| Aluminum | 10,000–100,000 shots | Prototyping, low-volume tooling |

| P20 Tool Steel | 100,000–500,000 shots | Medium-scale production |

| H13 Hardened Steel | 500,000–1,000,000+ shots | High-volume, long-term projects |

At Prime, we help clients choose the right mold base based on expected order quantity and part geometry. Our tooling experts conduct scheduled preventive maintenance to extend service life and delay tool retirement.

How do you tell if a product has been injection molded?

Before you decide whether a mold is still needed, you should verify that the parts it produced were indeed injection molded.

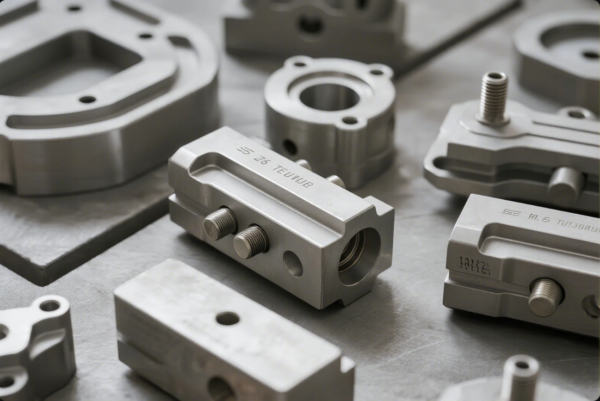

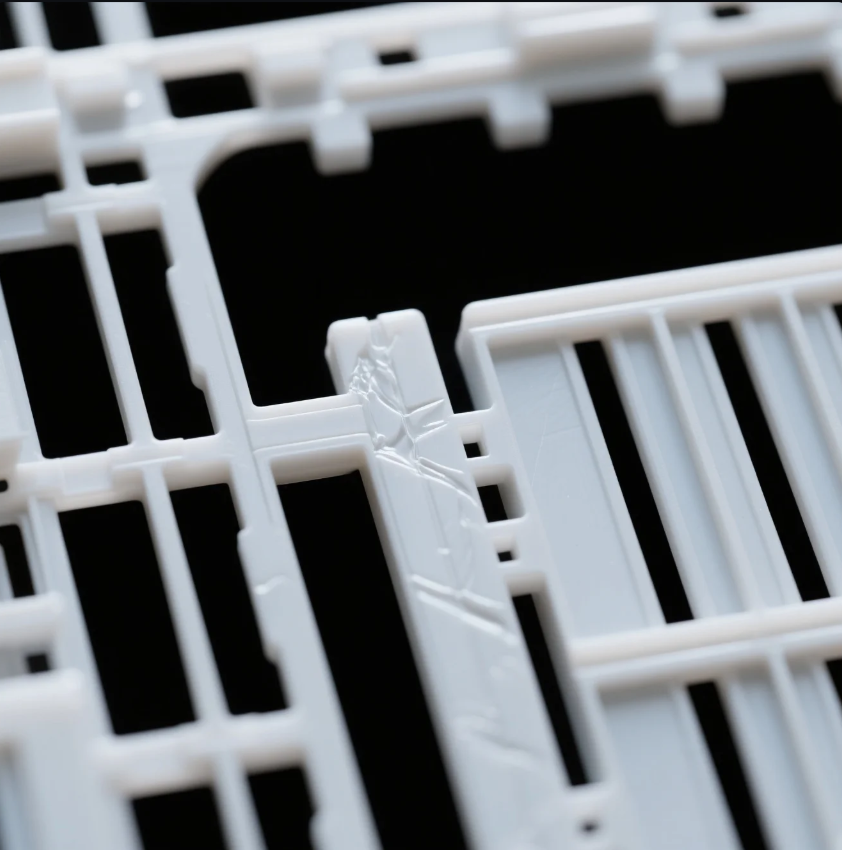

You can tell if a product was injection molded by identifying specific visual and structural characteristics like ejector marks, parting lines, and molded-in features.

Key Signs of Injection Molded Parts

- Parting lines – a thin seam on the edges where mold halves meet

- Ejector pin marks – small circles left by the ejector system

- Consistent wall thickness – typical of high-pressure molding

- Gate vestiges – leftover material at the point of resin entry

- Built-in clips, bosses, or logos – formed directly during molding

At Prime, we support clients in identifying whether legacy parts were molded, CNC machined, or 3D printed, which helps them decide if tooling should be rebuilt, reactivated, or discarded.

See our guide on identifying molded parts →

How many times can an injection mold be used?

One major reason companies invest in tooling is reusability. But how many cycles is “enough”?

A well-built injection mold can be used thousands—or even millions—of times. Each cycle creates identical parts, making molding ideal for mass production.

What Affects Mold Reusability?

| Factor | Impact on Mold Life |

|---|---|

| Material (e.g. H13 steel) | Higher hardness equals longer life |

| Mold design complexity | Complex tools wear faster |

| Resin type | Abrasive fillers reduce cycle count |

| Maintenance frequency | Proper cleaning increases longevity |

| Production environment | Dust and humidity accelerate wear |

At Prime, we maintain real-time mold history and usage logs for every project. This ensures we know when tools need polishing, repairs, or retirement. For high-volume clients, we often refurbish tools after 500,000 cycles to extend their lifespan.

Is injection molding recyclable?

Yes—and that applies to both the plastic materials and the molds themselves.

Injection molding can be highly sustainable. Thermoplastics can often be reground and reused. Steel molds can be recycled or repurposed into new tooling.

Sustainability in Molded Part Production

| Recyclable Item | Method of Reuse/Recycling |

|---|---|

| Plastic runners | Ground and blended into future batches |

| Molded scrap parts | Shredded and reprocessed (if tolerable) |

| Aluminum molds | Melted and re-machined for new tools |

| Steel molds | Scrapped or repurposed into fixture tooling |

At Prime, we help clients meet sustainability targets by selecting recyclable resins, minimizing runner waste through hot runner systems, and reconditioning old tools when possible.

See our approach to sustainable production →

What happens to old injection molds after production stops?

Here’s the core question: What happens to old injection molds after a part is discontinued, redesigned, or no longer in demand?

Depending on the client’s needs and mold condition, old injection molds are stored, refurbished, recycled, or scrapped.

Common Outcomes for Old Molds

-

Storage

- Molds are cleaned, rust-proofed, labeled, and archived

- Ideal for seasonal products or on-demand reorders

- Stored molds must be checked annually to prevent corrosion

-

Refurbishment

- Worn cores or inserts are replaced

- Polishing restores surface finish

- Cooling lines and guide pins are reconditioned

- Prime provides full mold reconditioning service on request

-

Recycling

- Steel or aluminum molds are scrapped and melted down

- Hardware (ejector systems, plates) is separated for reuse

-

Client Return or Disposal

- Some clients choose to export molds for in-house use

- Others authorize secure disposal after mold obsolescence

At Prime, we always consult with customers before retiring or scrapping tools. Molds are client-owned unless otherwise agreed, and we treat them as long-term production assets.

Contact us to check the status of your existing molds →

Conclusion

What happens to old injection molds depends on their material, condition, and demand—but they’re rarely just “thrown away.” With proper management, old molds can be stored, reused, or recycled for added value.

Need help evaluating your old molds or planning a tooling transition?

Contact Prime today at https://primecustomparts.com or https://primecustomparts.com for expert tooling analysis, storage support, or cost-saving mold refurbishing. We support full lifecycle mold strategies—from prototype to recycling.

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com