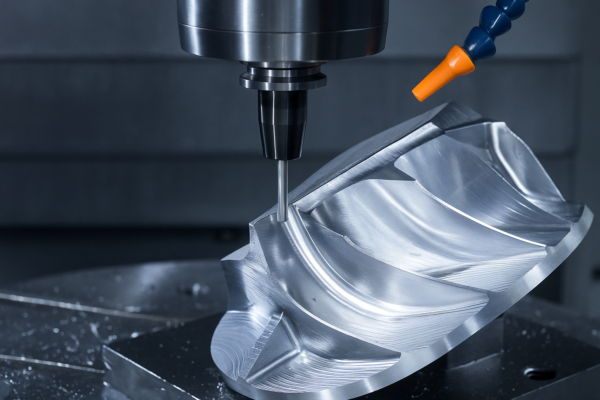

What Industries Benefit Most from Aluminum Set Screws Applications?

The frustration of using inappropriate fasteners can lead to product failure, increased weight, and poor electrical performance. Aluminum set screws solve these challenges by offering unique properties that benefit specific industries where traditional fasteners fall short.

Aluminum set screws are ideal for aerospace, electronics, marine, and automotive industries due to their lightweight properties (2.7 g/cm³ vs steel\’s 7.85 g/cm³), excellent electrical conductivity (30-40% IACS), and corrosion resistance in non-marine environments.

Before selecting standard steel fasteners for your next project, consider how the specialized properties of aluminum set screws might provide unexpected advantages in your specific application.

How Do Aluminum Set Screws Enhance Electrical Connection Performance?

The pain of poor electrical connections leads to energy loss, overheating, and potential system failure. Aluminum set screws with tin plating create reliable, high-conductivity connections that maintain performance even through thermal cycling.

Tin plated aluminum set screws are commonly used in OEM electrical aluminum bodied industrial wire connectors because they provide 50% higher conductivity than brass and twice that of steel, while expanding and contracting at the same rate as aluminum components.

Dive-Deeper paragraph: The electrical industry has unique requirements for fasteners that go beyond simple mechanical connection. When examining the role of aluminum set screws in electrical applications, we must consider both the primary electrical properties and the secondary effects that influence long-term reliability and performance.

Electrical Performance Metrics

To understand why aluminum set screws excel in electrical applications, consider these comparative performance metrics:

| — | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Electrical Conductivity (% IACS) | 30-40% | 15% | 28% | 3-15% | ||||||

| Contact Resistance Stability | Excellent | Poor | Good | Fair | ||||||

| Thermal Expansion Match with Al Components | Excellent | Poor | Fair | Poor | ||||||

| Galvanic Compatibility with Al | Excellent (with plating) | Poor | Fair | Poor | ||||||

| Weight | Very Light | Heavy | Heavy | Heavy |

Critical Electrical Applications

Power Distribution Equipment

In power distribution applications, aluminum set screws provide several advantages:

- Transmission Line Connectors

- Higher conductivity reduces energy losses

- Matched thermal expansion prevents loosening

- Lightweight design reduces structural load

- Cost-effective for large-scale deployments

- Busbar Connections

- Excellent current-carrying capacity

- Reduced hotspot formation

- Compatible with aluminum busbars

- Maintains connection integrity during thermal cycling

- Grounding Systems

- Corrosion resistance in controlled environments

- Good conductivity for fault current paths

- Compatible with aluminum ground conductors

- Reduced galvanic corrosion with proper plating

Industrial Control Systems

For industrial control applications, aluminum set screws offer:

- Motor Connections

- Vibration resistance with proper point style

- Good conductivity for power delivery

- Lightweight for rotating equipment

- Thermal stability in connection points

- Control Panel Terminations

- Space-efficient connections

- Reliable long-term performance

- Reduced maintenance requirements

- Compatible with aluminum panel components

As an electrical systems engineer explained to me during a recent project, "The consistency of the connection over time is just as important as the initial conductivity. Aluminum set screws with proper plating give us both the electrical performance and the mechanical stability we need for long-term reliability."

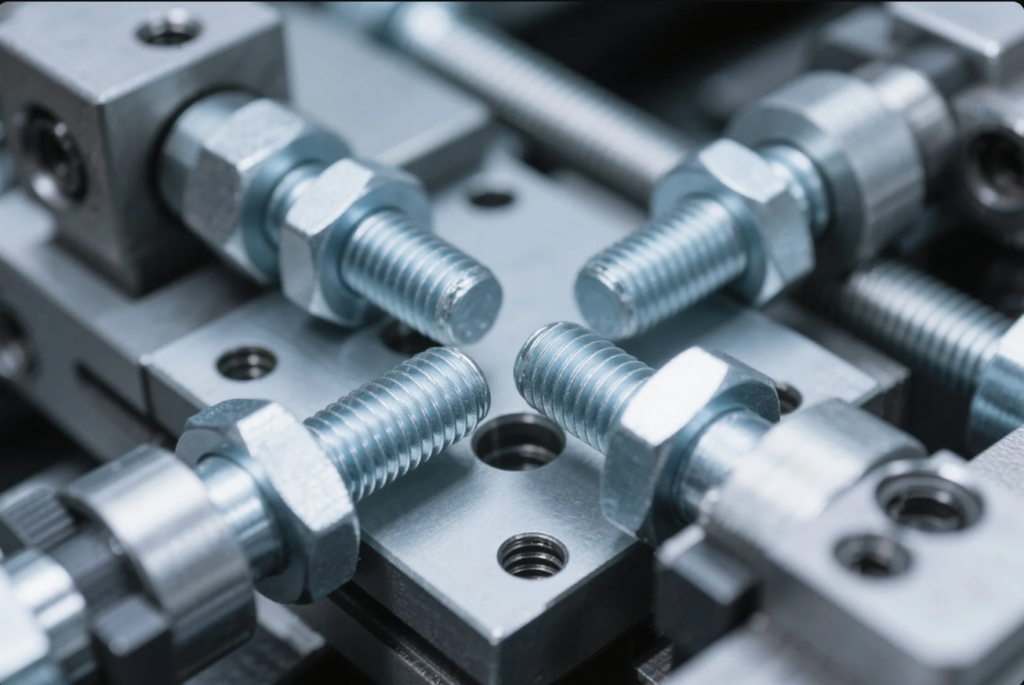

Why Are Aluminum Set Screws Critical in Aerospace Applications?

The challenge of excessive weight in aerospace applications directly impacts fuel efficiency, payload capacity, and operational costs. Aluminum set screws weigh just one-third of their steel counterparts, providing significant weight savings across thousands of connection points.

Aerospace applications benefit from aluminum set screws\’ 65% weight reduction compared to steel fasteners, while their non-magnetic properties prevent interference with sensitive navigation equipment and their corrosion resistance ensures reliability in pressurized cabin environments.

Dive-Deeper paragraph: The aerospace industry has some of the most demanding requirements for fasteners, with weight reduction being a primary driver but far from the only consideration. When we examine the full spectrum of aerospace needs, aluminum set screws demonstrate value across multiple dimensions that justify their specification in non-critical applications.

Aerospace-Specific Requirements

The unique operating environment of aircraft and spacecraft creates special demands:

| — | ||||||

|---|---|---|---|---|---|---|

| Weight Reduction | Excellent (65% lighter than steel) | Critical for fuel efficiency | ||||

| Fatigue Resistance | Good (with proper alloy selection) | Essential for vibration environments | ||||

| Temperature Range | Good (-65°F to 350°F) | Necessary for altitude changes | ||||

| Non-magnetic | Excellent | Critical for avionics | ||||

| Corrosion Resistance | Good (with proper treatment) | Important for longevity | ||||

| Thermal Conductivity | Excellent | Valuable for thermal management |

Aerospace Application Examples

Interior Components

Non-structural applications where aluminum set screws excel:

- Cabin Equipment Mounting

- Lightweight for fuel efficiency

- Non-magnetic for avionics compatibility

- Adequate strength for non-critical loads

- Corrosion resistant for cabin environment

- Instrument Panel Assembly

- Precise adjustment capability

- Vibration resistance with proper point style

- Weight savings across multiple fasteners

- Thermal conductivity for heat dissipation

- Galley and Lavatory Fixtures

- Corrosion resistance to cleaning agents

- Lightweight for overall aircraft efficiency

- Adequate strength for intended use

- Cost-effective for non-critical applications

Avionics and Electrical Systems

For electronic and electrical systems:

- Antenna Mounting Hardware

- Non-magnetic properties

- Lightweight design

- Corrosion resistance

- Electrical conductivity for grounding

- Wire Harness Securing Points

- Non-abrasive to wire insulation

- Lightweight across multiple attachment points

- Electrical continuity where required

- Thermal expansion compatible with aluminum structures

A senior aerospace fastener engineer once told me, "In aerospace, we don\’t just count pounds—we count ounces and even grams. When you multiply a small weight savings by thousands of fasteners, it adds up to meaningful performance improvements."

How Do Aluminum Set Screws Perform in Marine and Corrosive Environments?

The frustration of corroded fasteners that seize and become impossible to remove creates maintenance nightmares and safety hazards. Properly treated aluminum set screws offer corrosion resistance in specific marine applications, though with important limitations.

Anodized aluminum set screws provide good corrosion resistance in controlled environments, while tin-plated versions offer moderate protection in marine applications when properly isolated from galvanic couples, though they\’re not recommended for saltwater immersion.

Dive-Deeper paragraph: The corrosion behavior of aluminum set screws in marine environments requires careful consideration of multiple factors including the specific alloy, surface treatments, environmental exposure, and design details that affect moisture retention and galvanic coupling. A nuanced understanding of these factors is essential for appropriate application.

Marine Environment Corrosion Factors

The marine environment presents specific challenges for aluminum fasteners:

| — | ||||||

|---|---|---|---|---|---|---|

| Saltwater Exposure | Accelerated corrosion | Anodizing, isolation, regular maintenance | ||||

| Galvanic Coupling | Severe localized corrosion | Insulating washers, compatible metals, sacrificial anodes | ||||

| Crevice Corrosion | Concentrated damage in threads | Sealants, lubricants, regular inspection | ||||

| UV Exposure | Degradation of protective coatings | UV-resistant treatments, regular maintenance | ||||

| Temperature Cycling | Coating cracking, moisture ingress | Flexible coatings, thermal expansion consideration |

Marine Application Suitability

Above-Deck Applications

For components not directly exposed to saltwater immersion:

- Cabin Hardware

- Anodized aluminum set screws

- Regular maintenance schedule

- Protected from direct spray

- Isolation from dissimilar metals

- Electronics Mounting

- Sealed enclosures

- Corrosion-inhibiting compounds

- Regular inspection

- Replaceable fastener design

- Non-Critical Accessories

- Cost-effective for replaceable items

- Lightweight advantage

- Adequate corrosion resistance with proper treatment

- Regular maintenance program

Below-Deck Applications

For interior components with controlled exposure:

- Interior Cabinetry

- Limited moisture exposure

- Controlled humidity

- Non-structural applications

- Aesthetic considerations

- Electrical Panel Mounting

- Dry environment

- Electrical conductivity advantage

- Lightweight benefit

- Compatible with aluminum panels

A marine maintenance specialist with 25 years of experience shared this insight: "Aluminum fasteners can work well in the right marine applications, but you need to be realistic about their limitations. They\’re not \’set and forget\’—they require proper installation, isolation from dissimilar metals, and regular inspection as part of a comprehensive maintenance program."

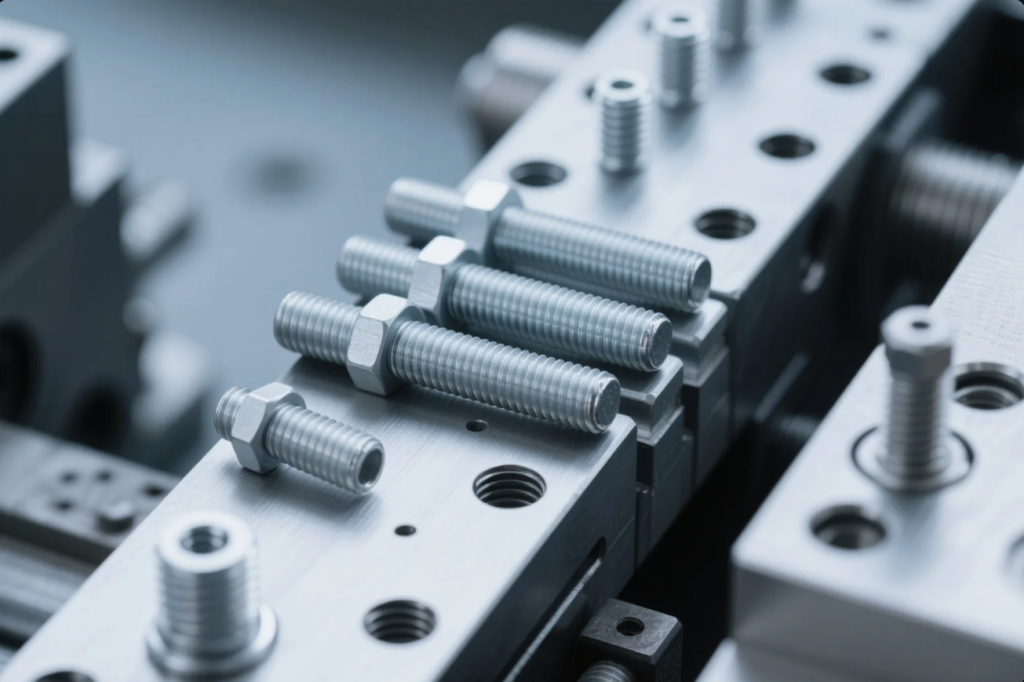

What Makes Aluminum Set Screws Ideal for Automotive Applications?

The challenge of meeting increasingly stringent fuel efficiency standards while maintaining performance and durability pushes automotive engineers to seek weight reduction in every component. Aluminum set screws contribute to this goal while offering additional benefits.

Automotive applications benefit from aluminum set screws\’ 65% weight reduction compared to steel, while their thermal conductivity (121-180 W/m·K vs. steel\’s 43 W/m·K) improves heat dissipation in electrical components and their corrosion resistance enhances longevity in non-structural applications.

Dive-Deeper paragraph: The automotive industry faces unique challenges in balancing performance, weight, cost, and durability across millions of vehicles. When examining the role of aluminum set screws in this context, we must consider both the primary benefits and the specific applications where these fasteners provide the greatest value proposition.

Automotive Performance Requirements

The demanding environment of modern vehicles creates specific fastener requirements:

| — | ||||||

|---|---|---|---|---|---|---|

| Weight Reduction | Excellent (65% lighter than steel) | Critical for fuel efficiency/range | ||||

| Vibration Resistance | Good (with proper point style) | Essential for durability | ||||

| Temperature Cycling | Good (-65°F to 350°F) | Necessary for engine proximity | ||||

| Corrosion Resistance | Good (with proper treatment) | Important for longevity | ||||

| Cost Effectiveness | Moderate | Critical for mass production | ||||

| Thermal Conductivity | Excellent | Valuable for electrical components |

Automotive Application Examples

Electrical Systems

For electrical components where aluminum set screws excel:

- Battery Terminal Connections

- Excellent electrical conductivity

- Lightweight design

- Corrosion resistance with proper plating

- Thermal conductivity for heat dissipation

- Electrical Control Modules

- Non-magnetic properties

- Lightweight for overall vehicle efficiency

- Thermal conductivity for heat management

- Adequate strength for intended use

- Sensor Mounting and Adjustment

- Precise adjustment capability

- Non-interference with sensor operation

- Lightweight design

- Corrosion resistance for longevity

Interior Components

For non-structural interior applications:

- Trim and Panel Mounting

- Lightweight across multiple attachment points

- Adequate strength for non-structural applications

- Cost-effective for high-volume production

- Corrosion resistance for vehicle lifetime

- Seat Adjustment Mechanisms

- Precise adjustment capability

- Lightweight design

- Adequate strength for intended use

- Corrosion resistance to interior environment

An automotive design engineer I consulted with explained, "Every gram matters when you\’re building millions of vehicles. The weight savings from switching to aluminum fasteners might seem small for a single component, but when you multiply it across an entire vehicle and then across a production run, the impact on fleet fuel economy becomes significant."

How Are Aluminum Set Screws Used in Medical and Scientific Equipment?

The problem of magnetic interference in sensitive medical and scientific equipment can compromise measurement accuracy and patient safety. Non-magnetic aluminum set screws provide secure fastening without disrupting magnetic fields in critical applications.

Medical and scientific equipment benefit from aluminum set screws\’ non-magnetic properties, making them ideal for MRI-compatible equipment, laboratory instruments, and precision measurement devices where magnetic interference must be eliminated.

Dive-Deeper paragraph: The medical and scientific fields have uniquely stringent requirements for materials used in equipment construction. When examining aluminum set screws in these contexts, we must consider not only their non-magnetic properties but also their compatibility with sterilization processes, chemical exposure, and precision requirements that differentiate these applications from industrial uses.

Medical and Scientific Requirements

The specialized needs of medical and scientific equipment create unique demands:

| — | ||||||

|---|---|---|---|---|---|---|

| Non-magnetic | Excellent | Critical for MRI compatibility | ||||

| Sterilization Compatibility | Good | Essential for medical equipment | ||||

| Chemical Resistance | Moderate (depends on treatment) | Important for laboratory use | ||||

| Precision Adjustment | Excellent (with proper design) | Critical for scientific instruments | ||||

| Lightweight | Excellent | Valuable for portable equipment | ||||

| Thermal Stability | Good | Important for measurement accuracy |

Medical and Scientific Applications

Medical Imaging Equipment

For MRI and other imaging systems:

- MRI-Compatible Accessories

- Completely non-magnetic

- Patient safety focus

- Adequate strength for intended use

- Compatible with sterilization protocols

- Positioning Equipment

- Precise adjustment capability

- Non-interference with imaging

- Lightweight for ease of positioning

- Corrosion resistance to cleaning agents

- Calibration Fixtures

- Non-magnetic for measurement accuracy

- Dimensional stability

- Precision adjustment capability

- Resistance to frequent handling

Laboratory Instruments

For precision scientific equipment:

- Optical Equipment Mounting

- Precise adjustment capability

- Vibration damping

- Non-magnetic for sensitive measurements

- Lightweight for portable instruments

- Sample Positioning Systems

- Fine adjustment capability

- Non-contaminating materials

- Chemical resistance

- Thermal stability for measurement accuracy

A medical equipment designer shared this perspective: "In medical imaging, particularly MRI, the non-magnetic property of aluminum fasteners isn\’t just a nice-to-have feature—it\’s an absolute requirement. Patient safety depends on eliminating any magnetic materials that could become projectiles in the strong magnetic field."

Contact Us

📧 Email us: [email protected]🌐 Visit: https://primecustomparts.com

Get a free quote, custom tool configuration, and fast delivery worldwide. Every order comes with setup support.

Conclusion

Aluminum set screws provide unique advantages across multiple industries, from electrical and aerospace to automotive and medical, offering lightweight construction, electrical conductivity, thermal compatibility, corrosion resistance, and non-magnetic properties that make them ideal for specialized applications.