What Is a Mold or Cast?

Molds and casts are fundamental in manufacturing, enabling the creation of complex shapes and designs. Understanding their differences and applications is crucial for selecting the appropriate process.

Snippet paragraph: Molds are hollow forms used to shape materials, while casts are the solid objects formed within molds. Both are essential in manufacturing for producing complex parts.

Let’s explore the distinctions between molds and casts, their applications, and how they contribute to various industries.

📚 Table of Contents

- What Is a Mold and Cast?

- What Are Examples of Casts and Molds?

- What Is Cast in Mold?

- What Is the Difference Between Cast and Mold?

- FAQs

- Contact Prime for a Material Consultation

What Is a Mold and Cast?

A mold is a hollow form or cavity into which a material is poured or pressed to create a specific shape. A cast is the solid object that results from the material hardening within the mold.

Snippet paragraph: A mold shapes materials by providing a cavity, while a cast is the final product formed within that cavity.

Dive Deeper: Understanding Molds and Casts

- Mold: Typically made from metal, plastic, or other materials, molds are designed to produce multiple copies of a part.

- Cast: The result of pouring a liquid material into a mold, which then solidifies into the desired shape.

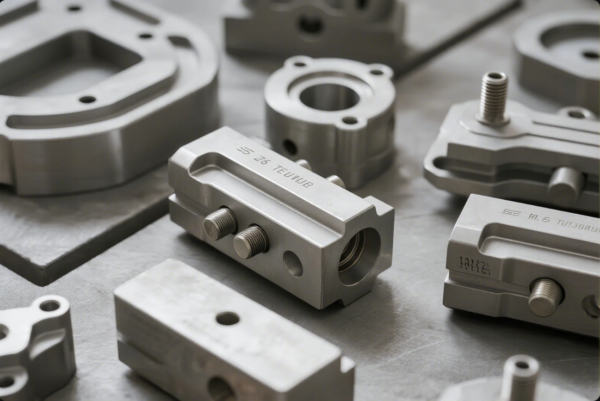

This process is widely used in various industries, including automotive, aerospace, and consumer goods, to produce parts with complex geometries.

What Are Examples of Casts and Molds?

Casts and molds are utilized in numerous applications across different industries.

Snippet paragraph: Examples include metal engine components, plastic containers, and artistic sculptures, all created using molds and casts.

Dive Deeper: Industry Applications

- Automotive: Engine blocks and transmission cases are often cast from metal using sand molds.

- Consumer Goods: Plastic bottles and containers are produced using injection molding.

- Art: Sculptures and jewelry are created by casting materials like bronze or resin into molds.

These examples demonstrate the versatility and importance of molds and casts in manufacturing and design.

What Is Cast in Mold?

"Cast in mold" refers to the process of pouring a liquid material into a mold where it solidifies into the desired shape.

Snippet paragraph: Casting in a mold involves pouring liquid material into a cavity, allowing it to harden into a specific form.

Dive Deeper: Casting Techniques

- Sand Casting: Involves creating a mold from sand and pouring molten metal into it.

- Die Casting: Uses high-pressure to force molten metal into a steel mold.

- Investment Casting: Employs a wax model coated with ceramic to create a mold for metal casting.

Each technique offers unique advantages depending on the material, complexity, and production volume required.

What Is the Difference Between Cast and Mold?

While closely related, casts and molds serve different functions in the manufacturing process.

Snippet paragraph: A mold shapes the material, while a cast is the final product formed within the mold.

Dive Deeper: Comparative Analysis

| Aspect | Mold | Cast |

|---|---|---|

| Function | Shapes the material | Final product formed in the mold |

| Material | Typically metal, plastic, or silicone | Depends on the application (metal, plastic, etc.) |

| Reusability | Often reusable | Single-use or end product |

| Application | Used to produce multiple parts | The part produced for use |

Understanding these differences is essential for selecting the appropriate process for manufacturing needs.

FAQs

Q1: Can molds be reused?

A1: Yes, many molds, especially those made from durable materials like steel, can be reused multiple times.

Q2: What materials can be cast?

A2: Common casting materials include metals (like aluminum and iron), plastics, and resins.

Q3: Is casting suitable for complex shapes?

A3: Absolutely, casting is ideal for creating complex and intricate designs that would be difficult to machine.

Q4: How does molding differ from casting?

A4: Molding typically involves shaping pliable materials like plastics, while casting involves pouring liquid materials into a mold.

Q5: What industries rely heavily on casting and molding?

A5: Industries such as automotive, aerospace, consumer goods, and art heavily utilize these processes.

Contact Prime for a Material Consultation

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com

Need guidance on the right molding or casting process for your project? Prime offers expert insights, global sourcing, and high-quality production—backed by over 20 years of experience and ISO-certified systems.

Conclusion

Molds and casts are integral to manufacturing, enabling the creation of complex and precise components across various industries. Understanding their differences and applications ensures the selection of the most effective production method.