What is Meant by Laser Cutting?

Many first-time buyers confuse laser fabrication with traditional cutting tools.

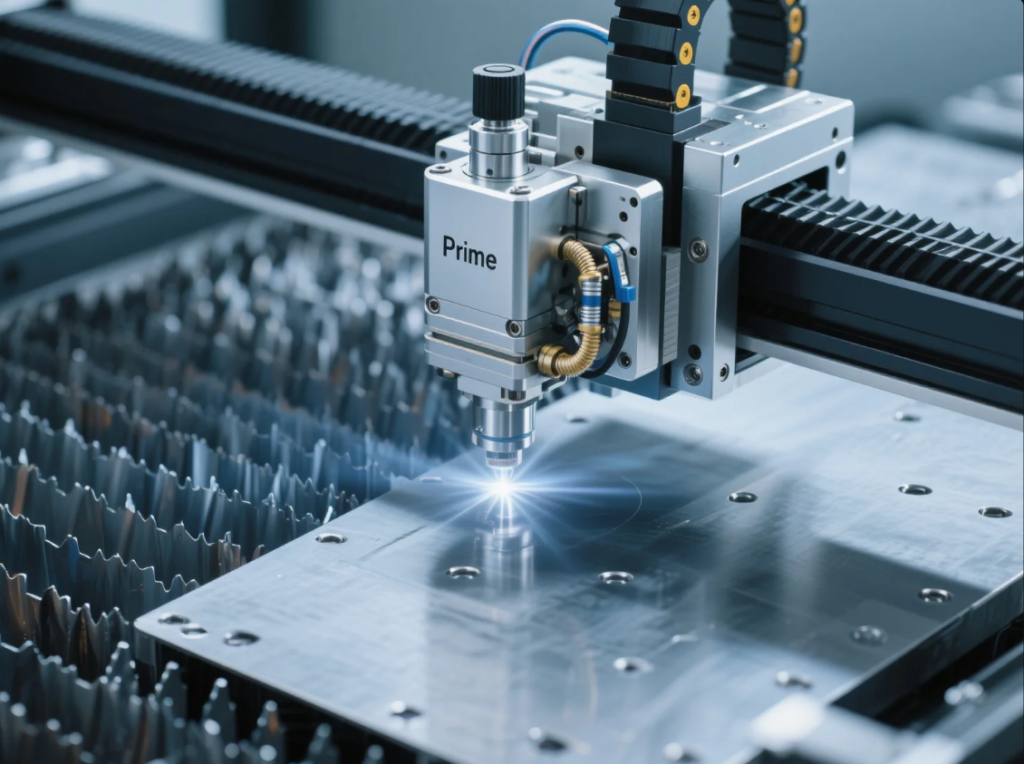

This advanced technology uses concentrated light beams to cleanly slice through materials without contact or wear.

If you’ve dealt with poor edge quality or inconsistent part dimensions, it’s time to explore this high-precision alternative.

What is the simple definition of laser cutting?

Many industrial buyers ask for clarification when comparing production methods.

It is a digital manufacturing method that uses a high-intensity light beam to cut shapes and outlines from various materials.

Unlike traditional saws or mechanical blades, this process uses a focused beam of light. It’s computer-controlled and doesn’t involve direct contact with the material, which means no deformation and little to no post-processing.

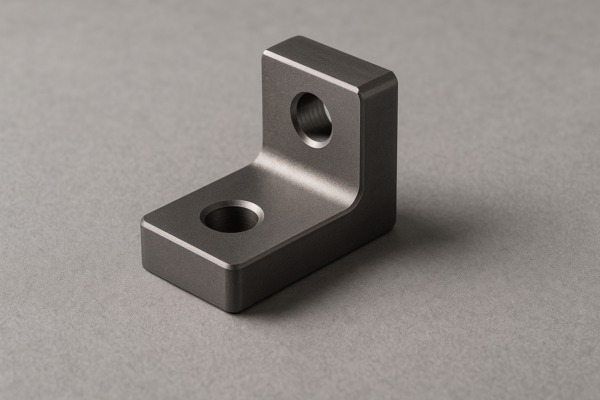

Laser systems can achieve extreme precision, often down to ±0.05mm, making them ideal for parts where accuracy is non-negotiable—such as custom CNC parts, precision brackets, or tight-fit enclosures.

Why do so many industries choose this technology?

Because it can handle a variety of materials:

- Metal: stainless steel, carbon steel, aluminum

- Plastic: acrylic (PMMA), Delrin, PETG

- Wood: MDF, plywood

- Composites: fiberboard, layered sheets

This flexibility makes laser fabrication one of the most versatile cutting methods on the market.

Real-world benefits:

- Cleaner edges, fewer secondary processes

- Tight tolerances for high-fit applications

- No physical blade = no wear or rework

- Design changes can be implemented digitally with no tooling cost

At Prime, we help buyers who need repeatability and scale. Whether it’s 100 aluminum chassis or 5,000 acrylic panels, our process ensures that every piece meets strict dimensional and visual requirements.

What is the laser cutting process?

Some think laser production is just “press a button and go.” But in industrial reality, it’s a sequence of detailed, calibrated steps.

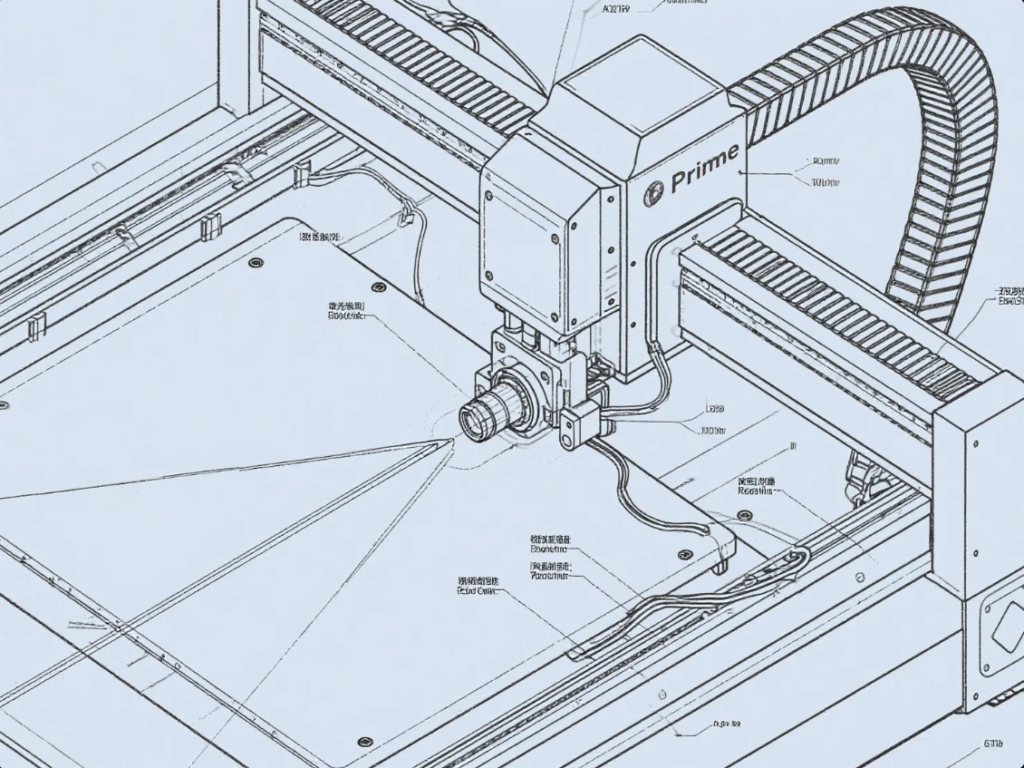

The laser cutting process involves material preparation, beam focus, software motion control, and post-cut inspection.

Here’s how Prime manages each order:

1. CAD Design and Nesting

We begin with your drawings, DXF or STEP files. Our engineers use nesting software to arrange shapes for maximum material efficiency.

2. Material Selection and Mounting

Sheets must be flat, debris-free, and consistent in thickness. We handle raw materials ranging from 0.5mm to 25mm.

3. Focus Adjustment

Different materials absorb laser energy differently. Stainless steel reflects more, while MDF burns easier. So we adjust the beam’s focus and intensity accordingly.

4. Assist Gas Application

We inject oxygen, nitrogen, or compressed air to clean the cut area. This prevents scorching and helps blow away molten residue for a cleaner edge.

5. Cutting Execution

Our software-driven machines move with sub-millimeter precision, even on complex geometries like rounded corners, notches, and small holes.

6. Deburring and Quality Control

Every part goes through edge inspection. We remove slag, inspect for burn marks, and verify dimensions digitally before shipping.

Prime’s approach combines automation with manual precision. Our ISO-certified team tracks each job digitally, ensuring that tolerance, surface finish, and packaging all meet the export client’s standard.

Looking for laser plus post-welding assembly? We do that too—in one factory.

What are the three types of laser cutting?

Choosing the wrong laser source can lead to poor cuts, discoloration, or warped parts.

There are three main types of laser sources: CO₂ lasers, fiber lasers, and crystal lasers. Each suits different materials and needs.

Quick comparison:

| Laser Type | Best For | Advantages | Limitations |

|---|---|---|---|

| CO₂ Laser | Plastics, wood, MDF, paper | Clean edges, smooth cuts | Not ideal for reflective metals |

| Fiber Laser | Carbon steel, stainless, aluminum | Fast, energy-efficient, compact | May burn edges on non-metals |

| Crystal Laser | Ultra-thin metal, micro-engraving | High precision, short wavelength | Expensive, short lifespan |

Prime’s Equipment Philosophy

We operate both fiber and CO₂ laser lines, selected based on your project. For example:

- Need 500 sheets of engraved acrylic panels? We’ll use CO₂

- Ordering 1,000 pieces of stainless steel brackets? Fiber is your tool

This flexibility ensures you never overpay for the wrong system.

Want to learn more? Check ScienceDirect’s laser cutting guide.

Is laser cutting the same as CNC cutting?

Not exactly—this is a common mistake even among seasoned buyers.

Laser cutting is one form of CNC-based processing. But CNC also includes milling, turning, and routing—each with different applications.

Key differences:

| Feature | Laser-Based Processing | Mechanical CNC Machining |

|---|---|---|

| Cutting Principle | Light beam melts or vaporizes material | Tool physically removes material |

| Best For | 2D outlines, holes, slots, engravings | 3D contours, threads, precision cavities |

| Material Wear | None (no contact) | Yes (tooling needs regular replacement) |

| Speed | Very high on thin sheet parts | Slower, especially on deep milling jobs |

| Accuracy | High (±0.05mm typical) | Higher in depth control and surface flatness |

At Prime, many of our customers combine the two. For instance, they:

- Cut outlines and holes using a laser

- Tap, thread, or machine edge details with CNC mills

This combo is common for custom fasteners, enclosures, and medical device panels. We provide a one-stop solution with fewer subcontractors, reduced lead times, and integrated inspection.

Conclusion

Laser processing provides unmatched versatility, precision, and speed across multiple industries and material types.

Ready to upgrade your supply chain?

Reach out to Prime today for free consulting, fast quotations, and guaranteed quality.