What is the 4-step drawing process?

The four-step drawing process is a crucial method in metalworking, primarily used to create deep and complex shapes from a flat sheet of metal. This process involves a series of carefully controlled steps that progressively stretch and form the metal into the desired shape. The drawing process is essential for creating parts like containers, cups, and other deep-drawn components that require a high degree of precision. In this article, we’ll explore the four-step drawing process and explain how each stage contributes to the final product.

Snippet paragraph: The four-step drawing process involves blank preparation, drawing, redrawing (if necessary), and finishing to create deep and complex shapes from metal.

Transition paragraph: Let’s dive deeper into each of these four steps to understand how the drawing process works in metal manufacturing.

What is the four-step drawing process?

The four-step drawing process is a systematic approach used to create deep shapes from metal. These steps are carefully structured to ensure that the metal is drawn evenly and without defects such as thinning or tearing. Let’s break down each step in the four-step drawing process:

- Blank Preparation: The raw metal is cut into the desired size and shape to create a blank, which will be used for drawing.

- Drawing: The blank is pulled through a die to form the desired shape, typically a deep or cup-like form.

- Redrawing (if needed): In some cases, the initial drawing does not produce the required depth. Redrawing helps achieve the necessary depth by drawing the material through the die again.

- Finishing: After the drawing and redrawing steps, the part is finished by trimming, cleaning, and applying any necessary coatings to ensure the final part meets quality standards.

Snippet paragraph: The four-step drawing process involves blank preparation, drawing, redrawing (if needed), and finishing to create high-quality, deep-drawn parts.

Dive Deeper:

Let’s take a closer look at each of these four critical steps:

-

Blank Preparation:

In this first step, the metal sheet is cut into a blank, which is the base material used in the drawing process. The blank must be the correct size and shape to ensure it can be properly drawn without defects. The blank is typically circular, though other shapes may be used depending on the final part’s design. The blank’s thickness is carefully considered, as thicker blanks are more resistant to stretching but may result in material wastage or defects if not handled correctly. -

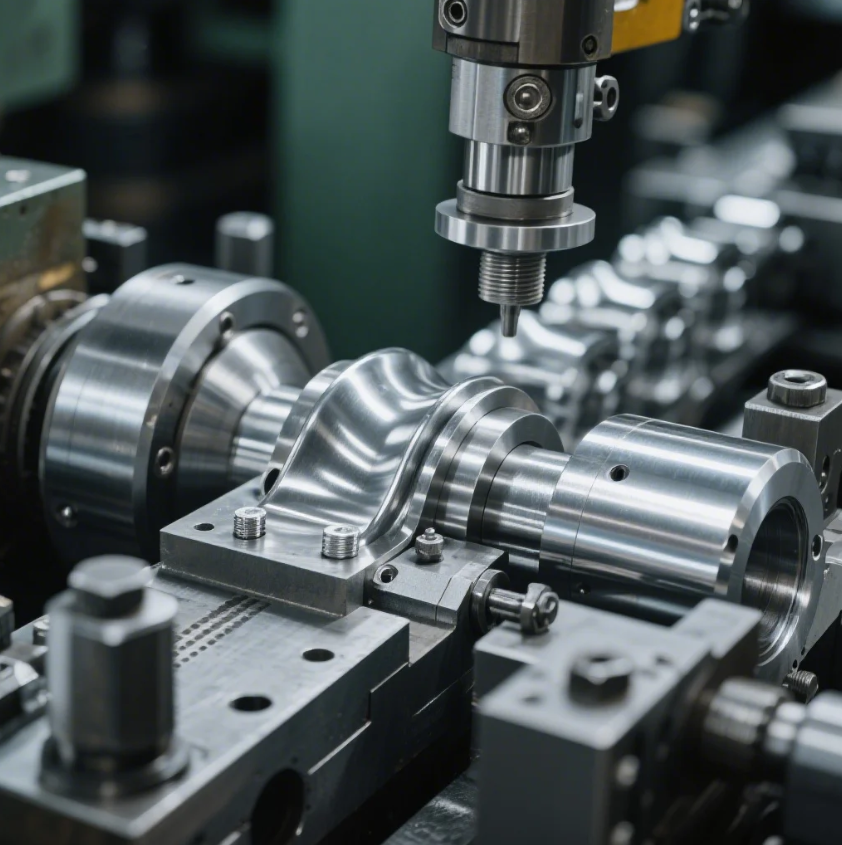

Drawing:

The blank is placed into a die, and a punch press pulls the material through the die. This step stretches the metal and forms it into a cup or other desired shape. The drawing process requires high precision and control to ensure that the material flows smoothly and evenly. Careful monitoring of the material’s behavior during drawing is necessary to prevent defects such as wrinkles or thinning. The first draw is usually the most challenging, as the metal is being stretched for the first time. -

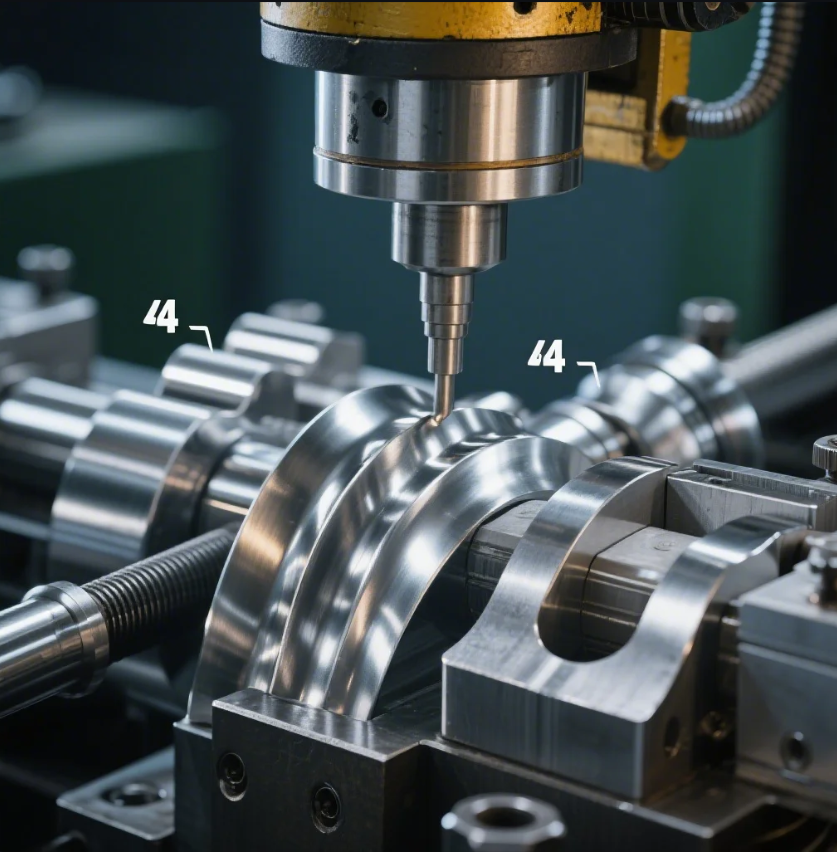

Redrawing (if needed):

In cases where the first draw does not produce the required depth or shape, redrawing is necessary. This step involves drawing the material through the die again, increasing the depth or refining the shape. Redrawing ensures that the part meets the required specifications for depth and geometry. During redrawing, the material may be stretched further, so it is crucial to carefully monitor the material’s behavior to prevent it from becoming too thin or weak. Redrawing also helps to eliminate any unevenness caused by the first draw. -

Finishing:

Once the part has been drawn (and redrawn, if necessary), it undergoes finishing to complete the manufacturing process. This step includes trimming any excess material, cleaning the part to remove oil or debris, and applying coatings or treatments for surface protection. The finishing process ensures that the part meets both functional and aesthetic requirements. In some cases, additional processes like deburring or polishing may be used to ensure the part’s final appearance is smooth and uniform.

What are the steps of the drawing process?

The drawing process consists of several stages that are essential for shaping a flat metal sheet into a three-dimensional form. The general steps in the drawing process can be broken down into three main phases:

- Blanking: Cutting the raw material into a blank that serves as the starting point for drawing.

- Drawing: The blank is pulled through the die to form a deeper shape, such as a cup or container.

- Finishing: After drawing, the part undergoes trimming, cleaning, and coating to prepare it for use.

Snippet paragraph: The drawing process involves blanking, drawing, and finishing to create parts with depth and complexity.

Dive Deeper:

In addition to these primary steps, the drawing process may include additional steps such as redrawing, as mentioned earlier, to refine the depth or shape. The specific stages in the drawing process may vary depending on the part being produced and the material used. For example, thicker materials may require more careful control during the drawing and redrawing steps to avoid defects like tearing.

What is drawing for Basic 4?

Drawing for Basic 4 refers to a fundamental version of the drawing process, which is often applied to simpler parts with less complexity. The "Basic 4" typically involves four main steps: blank preparation, drawing, redrawing (if needed), and finishing. This approach is used when the part design does not require highly intricate shapes or multiple stages of drawing. Basic 4 drawing is common in applications where the depth is not excessive and the part can be formed with fewer steps.

Snippet paragraph: Drawing for Basic 4 follows four main steps: blank preparation, drawing, redrawing (if necessary), and finishing, used for simpler parts.

Dive Deeper:

The Basic 4 drawing process is effective for creating parts that do not require excessive depth or complex geometries. These parts are typically produced using a single draw or a minimal amount of redrawing, making the process more straightforward and cost-effective. For example, a shallow dish or container can be produced using Basic 4 drawing. The process allows for efficient production, though it may not be suitable for parts with deep or intricate shapes that require multiple draws.

What are the stages of drawing?

The stages of the drawing process can be summarized into four primary phases: blank preparation, drawing, redrawing (if required), and finishing. However, each of these stages involves a variety of specific actions and techniques to ensure the final part meets the required specifications. Here’s an overview of each stage:

- Blank Preparation: The metal is cut into the correct size and shape for the drawing process.

- Drawing: The blank is pulled through the die to create the desired part.

- Redrawing (if necessary): Additional drawing steps may be required to achieve the correct depth or shape.

- Finishing: The part is trimmed, cleaned, and coated to prepare it for use.

Snippet paragraph: The stages of drawing include blank preparation, drawing, redrawing (if needed), and finishing, each ensuring the part meets the specifications.

Dive Deeper:

Each stage of the drawing process contributes to the final part’s quality. The blank preparation stage ensures that the material is the right size for efficient processing. Drawing is the core phase where the part starts taking shape. Redrawing refines the part’s depth and geometry, and finishing ensures that the part is functional, clean, and free of defects.

Conclusion

The four-step drawing process is an essential part of metalworking, enabling manufacturers to create deep, complex parts from flat metal sheets. Understanding each of the steps—blank preparation, drawing, redrawing (if necessary), and finishing—helps ensure that the final part meets high-quality standards. At Prime, we specialize in drawing processes for a wide range of applications, ensuring precision and fast turnaround times. Contact us today for more information and a customized quote!