What is the average cost of an injection mold?

Wondering how much an injection mold really costs?

The average cost of an injection mold ranges from \$1,000 to \$100,000+, depending on part complexity, material, size, surface finish, and production volume. Most standard production molds fall between \$5,000 and \$25,000.

Understanding the cost of an injection mold helps buyers plan budgets and avoid unexpected expenses. In this article, we’ll explain how to calculate mold cost, what drives pricing, and how mold lifespan affects total investment value.

How to calculate injection mold cost?

Calculating mold cost involves analyzing multiple variables—most importantly, the design requirements and production volume.

Mold cost is based on part geometry, material selection, number of cavities, surface finish, tolerances, and expected lifespan.

Key Factors That Affect Mold Price

| Factor | Impact on Cost |

|---|---|

| Part size and complexity | More material and machining increase cost |

| Mold material | Aluminum molds are cheaper than hardened steel |

| Cavity count | Multi-cavity molds cost more but lower part cost |

| Surface finish | High-gloss or texture increases polishing time |

| Tolerance requirement | Tight tolerances require higher precision tooling |

At Prime, we offer both budget-friendly aluminum molds for low-volume runs and high-performance hardened steel molds for long-term production. We also provide clear pricing breakdowns, including cost per cavity, design, and sample testing.

Request a detailed mold cost quote →

What is the hourly rate for injection molding?

In addition to mold cost, you should also know the running cost of producing parts.

The hourly rate for injection molding typically ranges from \$50 to \$150 per hour, depending on machine size, automation level, part complexity, and material.

Breakdown of Hourly Rates by Machine Size

| Machine Tonnage | Typical Hourly Rate | Ideal For |

|---|---|---|

| <100T | \$50–70/hour | Small parts, prototyping |

| 100–300T | \$70–100/hour | Consumer goods, general parts |

| 300–600T | \$90–120/hour | Automotive, large enclosures |

| >600T | \$120–150+/hour | Furniture, industrial products |

Hourly rates include machine depreciation, electricity, operator wages, maintenance, and cooling water. At Prime, we reduce per-part costs by using multi-cavity molds and running 24/7 production shifts.

See Prime’s capabilities by tonnage →

Why is injection mold so expensive?

If you’ve ever received a mold quote and asked, “Why is this so expensive?”, you’re not alone.

Injection molds are expensive because they are precision-engineered, custom-made tools that must withstand high pressure, heat, and wear for hundreds of thousands of cycles.

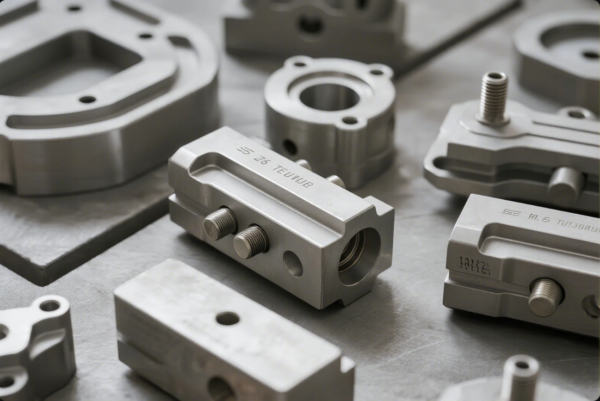

Image: A complex mold base with precision ejector systems being assembled at Prime.

Why Mold Cost Reflects Value

- Custom Engineering – Every mold is built to fit one specific part

- Tool Steel & Machining – High-grade steel, EDM, and CNC take time and cost

- Cooling Systems – Internal channels must be machined for efficiency

- Tolerances – Micron-level accuracy is required for functional parts

- Durability – Molds must last for thousands or millions of cycles

At Prime, we design every mold for your production goals. A \$5,000 prototype mold might last for 5,000 cycles, while a \$30,000 hardened mold could run 1 million shots—lowering the cost per part significantly over time.

Get a lifecycle ROI analysis for your mold →

What is the lifespan of an injection mold?

Your mold cost only makes sense when you know how long it will last.

Aluminum molds may last 10,000–100,000 cycles, while hardened steel molds can exceed 1 million cycles with proper care. The longer a mold lasts, the more it amortizes over production.

Image: Shot counter device logging the number of parts produced by a steel mold in operation.

Mold Lifespan by Type

| Mold Type | Estimated Lifespan | Use Case |

|---|---|---|

| Aluminum | 10k–100k cycles | Prototypes, low-volume |

| P20 Steel | 100k–500k cycles | General-use, medium-volume |

| H13 / S136 Steel | 500k–1M+ cycles | Long-term, high-volume |

At Prime, we track mold condition using digital counters and scheduled maintenance. We offer repair, re-polishing, and insert replacement services to extend tooling life even further.

Explore Prime’s mold lifespan guarantee options →

Conclusion

The cost of an injection mold depends on many factors—but it’s an investment that pays off when properly matched to your production needs. Always balance upfront tooling cost with expected part volume, mold life, and long-term efficiency.

Need an accurate mold cost estimate or cost-per-part analysis?

Contact Prime today at https://primecustomparts.com or https://primecustomparts.com for a free quote, design review, and tooling consultation. Whether you need a prototype mold or long-life tooling, we deliver high-quality results with transparent pricing.

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com