What is the Best Metal for Metal Casting?

Metal casting buyers often struggle with material selection. Quality, cost, and supplier trust are the biggest challenges. Many buyers worry about missed deadlines, poor communication, and non-compliance with ISO standards.

Many buyers want to know which metal is best for casting. The answer depends on strength, price, weight, and application. Steel, iron, and aluminum remain industry leaders. Each metal offers unique benefits, fitting different technical and commercial needs.

Selecting the right casting metal impacts your profit, reputation, and production timeline. A wrong choice may cause high defect rates or lost market share. In this guide, I use 20+ years of Prime B2B experience, blending client case studies and practical advice. The goal is to help you make the best sourcing decision—and avoid the pitfalls that harm many buyers.

What is the Best Steel for Casting?

Metal casting buyers often feel lost when choosing steel. There are many grades, each with different mechanical and chemical properties. If you select the wrong steel, costs and failure risks can skyrocket. In B2B, reputation loss can be hard to fix.

Steel castings stand out for high strength, toughness, and long service life. Carbon steel and stainless steel are the most common choices. Carbon steel is ideal for heavy-duty parts. Stainless steel is perfect for applications needing corrosion resistance and hygiene.

Many automotive, construction, and medical clients ask me which steel grade to use. For general machinery, AISI 1020 carbon steel is cost-effective. For marine and food processing, 304 stainless steel meets both performance and regulatory needs.

Types of Steel Used in Casting

| Steel Type | Strength | Corrosion Resistance | Price Level | Main Applications | External Guide |

|---|---|---|---|---|---|

| Carbon Steel | High | Low | Low | Machine frames, automotive, tools | AZoM |

| Alloy Steel | Very High | Medium | Medium | Gears, axles, aerospace | Total Materia |

| Stainless Steel | High | Very High | High | Food, pumps, medical, marine | BSSA |

| Tool Steel | Very High | Low | Very High | Molds, dies, wear parts | Tool Steel |

How to Select the Right Steel Grade

- Always request a material certificate from your supplier.

- Make sure the supplier is ISO 9001 certified.

- Check if your supplier has passed SGS inspection or Bureau Veritas audits.

You can compare standards using Matmatch or Engineering Toolbox.

Which is the Most Widely Used Metal for Castings?

Buyers need reliable, high-volume materials to manage risk and price. I’ve consulted for OEMs who need parts for tractors, compressors, or water pumps. They usually prioritize cost and casting ease.

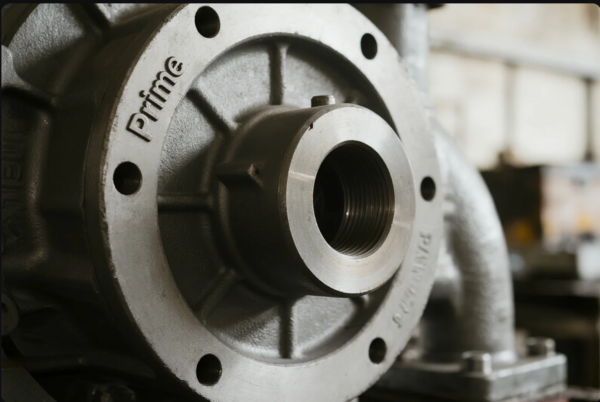

Gray iron is the world’s most widely used casting metal. It offers unbeatable castability, low price, and great vibration damping. Engine blocks, valve bodies, and pump housings all rely on gray iron’s unique properties.

In my practice, gray iron accounts for over 50% of all metal castings ordered by North American and European clients. Its graphite structure allows intricate shapes and protects machinery from shock.

Why Gray Iron Leads the Market

- It is affordable and readily available from suppliers like Dandong Foundry.

- Gray iron’s machinability reduces overall production time and cost.

- If you need a non-structural or non-corrosive part, gray iron saves budget and time.

For large structural or pressure-bearing parts, ductile iron is preferred by municipal and energy industries.

Main Casting Metals Comparison

| Metal | Cost | Castability | Strength | Uses | Authority Link |

|---|---|---|---|---|---|

| Gray Iron | Low | Excellent | Medium | Engines, housings, pumps | AFS |

| Ductile Iron | Medium | Very Good | High | Pipes, gears, heavy machinery | Dura-Bar |

| Aluminum | Medium | Excellent | Medium | Auto, aerospace, housings | Aluminum.org |

| Steel | High | Good | Very High | Tools, high-stress parts | Worldsteel |

What Metal is Widely Used for Casting?

Some clients require lighter, corrosion-resistant, or visually appealing components. Electronics, automotive, and marine industries demand better performance and style.

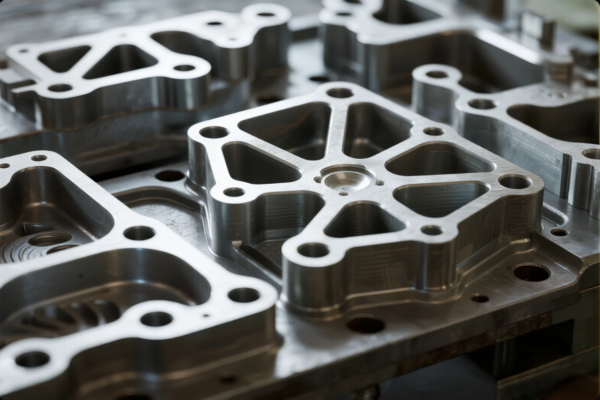

Aluminum is a top choice for high-volume, light-weight castings. Zinc is used for small precision parts. Brass is the go-to for corrosion-resistant or decorative parts.

I recommend die casting aluminum for clients focusing on weight and corrosion resistance. Zinc die casting is ideal for electronics or connectors. For marine hardware or luxury fixtures, brass is often required by European designers.

Table: Widely Used Casting Metals

| Metal | Density | Corrosion Resistance | Price | Main Uses | Industry Resource |

|---|---|---|---|---|---|

| Aluminum | Low | High | Medium | Automotive, aerospace | Aluminum.org |

| Zinc | Medium | High | Low | Small, precise components | NADCA |

| Brass | High | Very High | High | Plumbing, decorative, marine | Copper.org |

For high-volume OEM projects, I advise benchmarking with industry leaders and requesting sample tests. See Die Casting World and Foundry Planet for the latest global trends.

What is the Most Common Metal Used in Casting?

Many sourcing managers want one reliable, standard answer. Consistency and supply chain security matter most for large, ongoing orders.

Gray iron remains the dominant casting metal worldwide, especially for industrial equipment and general engineering. It balances cost, machinability, and reliable global supply.

In my experience, gray iron is specified for most machinery, construction equipment, and pumps. It’s the default unless your application requires more advanced properties.

| Feature | Gray Iron | Aluminum | Steel |

|---|---|---|---|

| Cost | Low | Medium | High |

| Weight | High | Low | High |

| Castability | Excellent | Excellent | Good |

| Strength | Medium | Medium | High |

| Corrosion Resistance | Low | Medium | High |

For further reading, I suggest American Foundry Society, GlobalSpec, and Grand View Research.

How to Choose the Right Metal for Your Project?

The best results come from a step-by-step approach. Successful projects depend on clear communication, certified suppliers, and matching material to function.

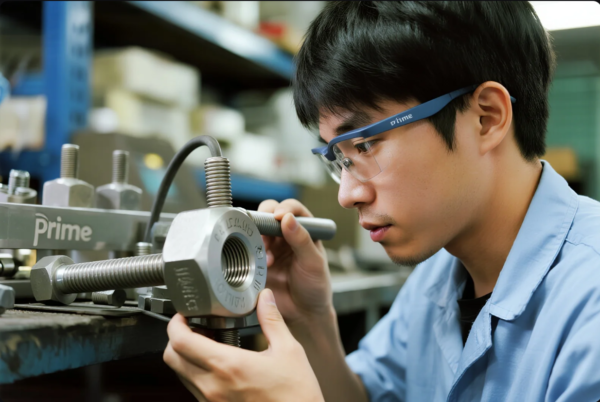

Evaluate mechanical, environmental, and industry-specific demands. Partner with an ISO-certified supplier like Prime for technical advice and end-to-end service.

Step-by-Step Guide

- Define Application

Use Engineering Toolbox to list needs. - Certification Needs

Ask for ISO, IATF, or CE compliance. - Total Cost of Ownership

Consult with ReliabilityWeb. - Supplier Reliability

Review profiles on Alibaba, Made-in-China, and Trustpilot. - Samples and Testing

Use TÜV Rheinland for third-party validation.

If you want more practical examples, see The Balance – Casting Process and Matmatch.

Key Factors: Customization, Certification & Supplier Reliability

Clients often overlook details like design adjustment, quality traceability, and supplier audits. These factors decide project success and long-term relationships.

Choose suppliers offering custom logo, flexible design changes, and traceable production. Demand ISO 9001:2015, CE, or RoHS certification. Use SGS, Bureau Veritas, and QIMA for audits.

- Ensure global delivery with DHL, FedEx, and Maersk.

- Check packaging and labeling with Uline and Labelmaster.

Prime’s team has over 20 years of experience, 10+ production lines, and robust technical support.

Packaging, Quality Control and Logistics: What Matters Most

Improper packaging and unreliable logistics can ruin even the best parts. Clients often share stories of customs holds, damaged parts, or late shipments.

Demand waterproof wrapping, custom crates, and batch testing. Require pre-shipment inspection, real-time tracking, and shipment insurance.

- Study international packaging standards.

- Understand Incoterms to avoid hidden costs.

- Ask about logistics partnerships.

Suppliers who cut corners here cost you money, time, and trust.

FAQS

Q1: Which is better for automotive parts, aluminum or gray iron?

A1: Aluminum is lighter and ideal for fuel efficiency. Gray iron is cheaper and better for vibration damping in large blocks.

Q2: How can I check a supplier’s certification?

A2: Ask for ISO 9001 certificates, cross-check with TÜV Rheinland, or use SGS audits.

Q3: What is the average lead time for custom casting parts?

A3: Prime delivers in 3-4 weeks for most projects. Check with your supplier for exact timing.

Q4: How do I ensure parts arrive undamaged?

A4: Use suppliers with reinforced packaging, pre-shipment inspection, and global partners like DHL.

Q5: What if I need unique alloys or tight tolerances?

A5: Work with custom parts suppliers able to offer special alloys and provide quality reports.

Q6: Can I visit your factory or see video audits?

A6: Yes. Prime supports on-site and virtual audits.

Q7: Which casting process is best for my product?

A7: Die casting suits large volumes. Investment casting is best for complex shapes. Sand casting is most flexible.

Q8: Can I order from the USA or Europe?

A8: Yes. Prime exports globally, using FedEx, Maersk, and UPS.

Q9: What are the payment terms?

A9: Common options include T/T, L/C, and PayPal, depending on order size.

Contact Us for a Free Consultation

For fast quotes, engineering support, or the most reliable [custom casting solutions

](https://primecustomparts.com/), contact Prime today.

Get ISO-certified quality, quick delivery, and dedicated service for your next industrial project.

Contact us:

- 🌐 Website: https://primecustomparts.com/

- 📧 Email: [email protected]

Conclusion

The best casting metal fits your business and technical needs. Rely on Prime for expert support, stable quality, and rapid delivery—reach out for a free quote now.