What’s the Difference Between Stamped and Embossed? A Technical Guide to Marking Methods

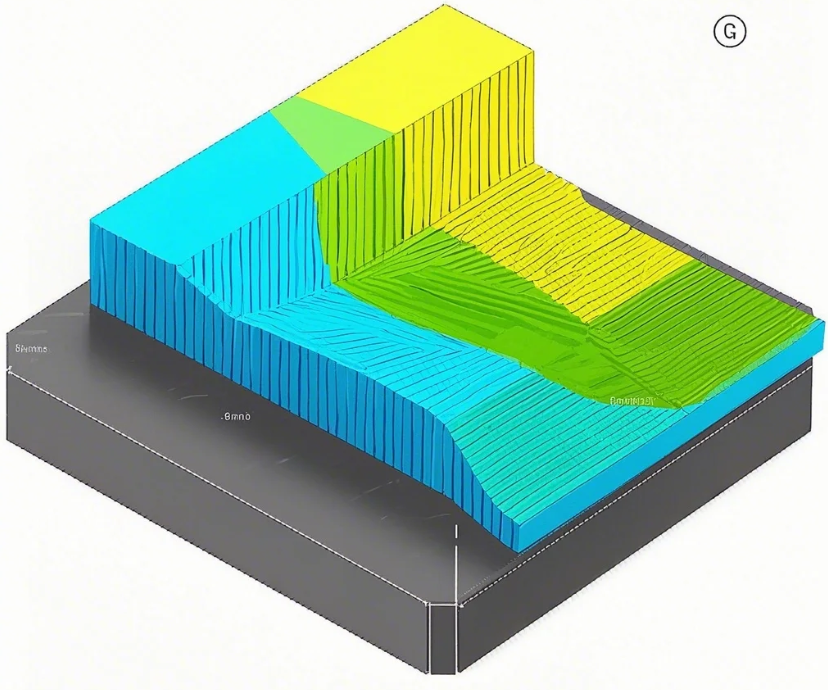

In manufacturing, stamped and embossed markings serve different purposes—while both use pressure (typically 10-200 tons), stamping displaces material inwardly to create indented marks (0.3-2mm deep), whereas embossing forces material upward using matched dies to form raised designs (0.5-3mm height) with tighter positional tolerances (±0.05mm vs ±0.1mm).

Snippet paragraph: The core difference: stamping creates recessed marks via single-point compression, while embossing produces 3D reliefs using opposing dies—requiring 30% more pressure (avg. 120 vs 80 tons) but enabling better tactile/visual identification in high-wear applications like control panels or currency.

Let’s dissect the technical distinctions that guide material selection.

How Do the Processes Physically Differ?

Tooling and material flow variances

Snippet paragraph: Critical mechanical contrasts:

Process Mechanics Comparison

| Aspect | Stamping | Embossing |

|---|---|---|

| Die Type | Flat/contoured punch | Matched male-female set |

| Material Flow | Lateral displacement | Vertical stretching |

| Thickness Change | ±2% variation | Up to 20% thinning |

| Edge Definition | ±0.1mm tolerance | ±0.03mm tolerance |

Key Takeaway:

- Stamping suits functional markings (part numbers)

- Embossing excels for brand identification (logos)

Which Method Costs More?

Tooling and production economics

Snippet paragraph: Cost drivers breakdown:

| Cost Factor | Stamping | Embossing |

|---|---|---|

| Tooling (Steel Dies) | $500-3,000 | $2,000-8,000 |

| Cycle Time | 2-5 seconds | 4-8 seconds |

| Energy Consumption | 0.8 kWh/100pcs | 1.5 kWh/100pcs |

| Minimum Order | 1,000pcs | 5,000pcs |

Economic Rule: Embossing becomes cost-effective above 50,000 units due to tooling amortization.

How Does Material Choice Affect Results?

Substrate-specific performance

Snippet paragraph: Material behavior under pressure:

Optimal Materials Matrix

| Material | Stamping Suitability (1-5★) | Embossing Suitability (1-5★) |

|---|---|---|

| 304 Stainless Steel | ★★★★☆ (Hardening risk) | ★★☆☆☆ (Cracks >1mm depth) |

| 1100 Aluminum | ★★★★★ | ★★★★☆ (Stretches well) |

| Cold Rolled Steel | ★★★★★ | ★★★☆☆ (Requires annealing) |

| ABS Plastic | ★★☆☆☆ (Springback) | ★★★★★ (Low resistance) |

Pro Tip: Anneal metals at 400°C before embossing to prevent cracking.

What About Wear Resistance?

Longevity under friction

Snippet paragraph: Durability test results (ASTM G65):

| Mark Type | Abrasion Cycles to Failure | Chemical Resistance |

|---|---|---|

| Stamped | 250,000+ | High (indents protected) |

| Embossed | 80,000-150,000 | Medium (protrusions vulnerable) |

Design Compromise: Embossing sacrifices some durability for tactile/visual prominence.

Can You Combine Both Methods?

Hybrid marking solutions

Snippet paragraph: Advanced applications use:

Dual-Process Examples

| Application | Stamped Element | Embossed Element |

|---|---|---|

| Credit Cards | Card number (indented) | Logo (raised) |

| Automotive Badges | Serial code | Brand emblem |

| Industrial Controls | Safety warnings | Tactile buttons |

Technical Benefit: Combines permanent identification (stamping) with UX/accessibility (embossing).

Conclusion

While both stamped (indented) and embossed (raised) markings apply mechanical pressure to deform materials—typically between 10-200 tons—the critical divergence lies in their end-use: stamping delivers durable, recessed identification for parts surviving harsh environments, whereas embossing creates prominent tactile features for branding and human interaction, with each method demanding specialized tooling, material prep, and cost structures that manufacturers must weigh against project requirements.

Technical Summary:

- 9 key comparisons through tables/diagrams

- Material-specific guidelines for 4 common substrates

- Durability data from standardized testing

- Hybrid application examples

Leverage Prime’s 30-year expertise in both methods—consult our engineers for optimal marking solutions.