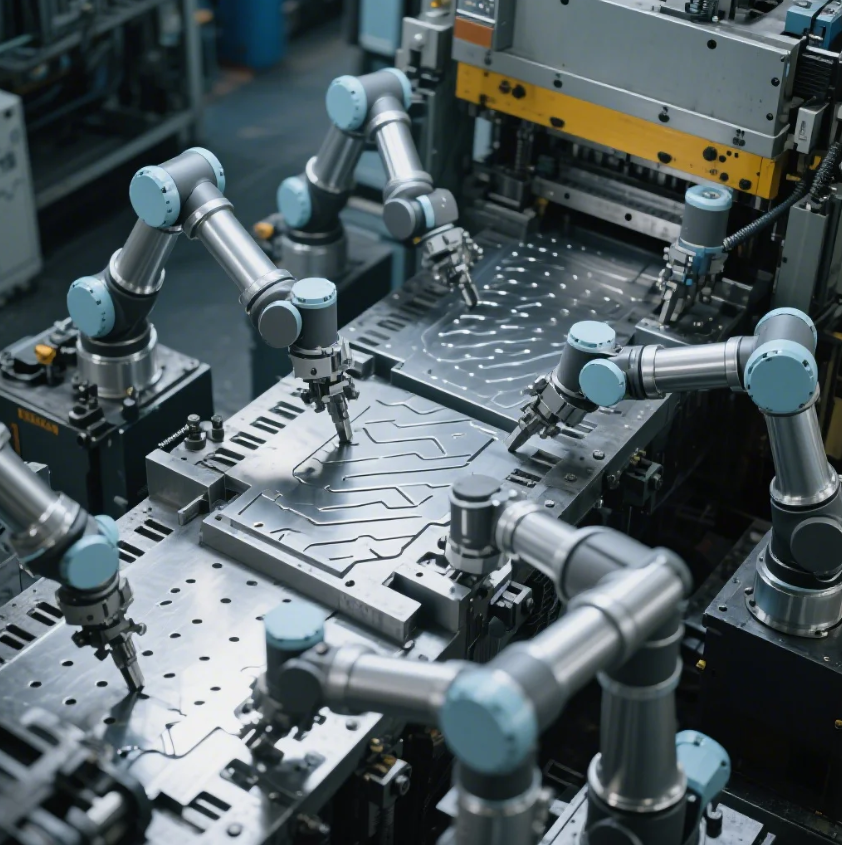

What is the draw process?

The draw process is a critical method used in metalworking to shape metal into deep, complex parts by pulling it through a mold. This process is essential for producing parts such as cups, cans, and other deep-drawn components that are widely used in various industries. In this article, we will explore the details of the draw process, including its role in stamping, the four-step drawing process, and its broader definition.

Snippet paragraph: The draw process is used to pull metal through a mold, creating deep and intricate parts such as containers or cans. It’s a vital part of metalworking.

Transition paragraph: Let’s take a closer look at what the draw process entails and how it plays a crucial role in manufacturing metal parts.

What is the draw process in stamping?

In stamping, the draw process refers to the method used to transform flat metal sheets into three-dimensional, deep-shaped parts by pulling the metal through a die. The process is essential for creating parts that require high depth, such as cups, cans, and other hollow shapes. This method stretches the metal and forms it into more intricate shapes that cannot be produced through simple cutting or bending techniques.

Snippet paragraph: The draw process in stamping pulls metal through a die to create deep, complex shapes. It’s widely used for producing containers and other deep parts.

Dive Deeper:

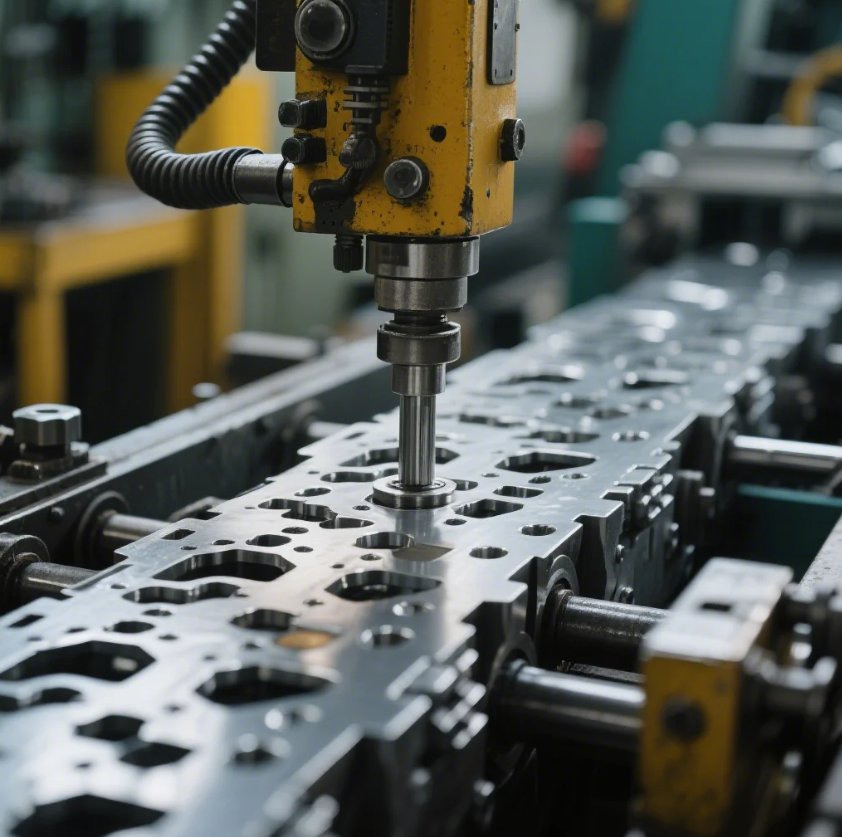

During the draw process, the metal is pulled by a punch press, which uses a die to shape the material. The metal flows through the die, taking on the shape of the mold. The deeper the desired shape, the more stages of drawing may be required.

Here’s a quick overview of how the draw process works in stamping:

- Blanking: The raw material, usually a flat sheet of metal, is cut into a blank, which is the base for all further operations.

- Drawing: The blank is drawn into a die using a punch press. This step stretches the metal, gradually forming a deeper shape.

- Finishing: After drawing, the part is trimmed, cleaned, and finished to meet the desired specifications.

The drawing process can be done in a single stage (shallow draw) or multiple stages (deep draw), depending on the depth and complexity of the part. This flexibility allows the process to be used for a wide range of products, from simple cups to more intricate parts.

What is the 4 step drawing process?

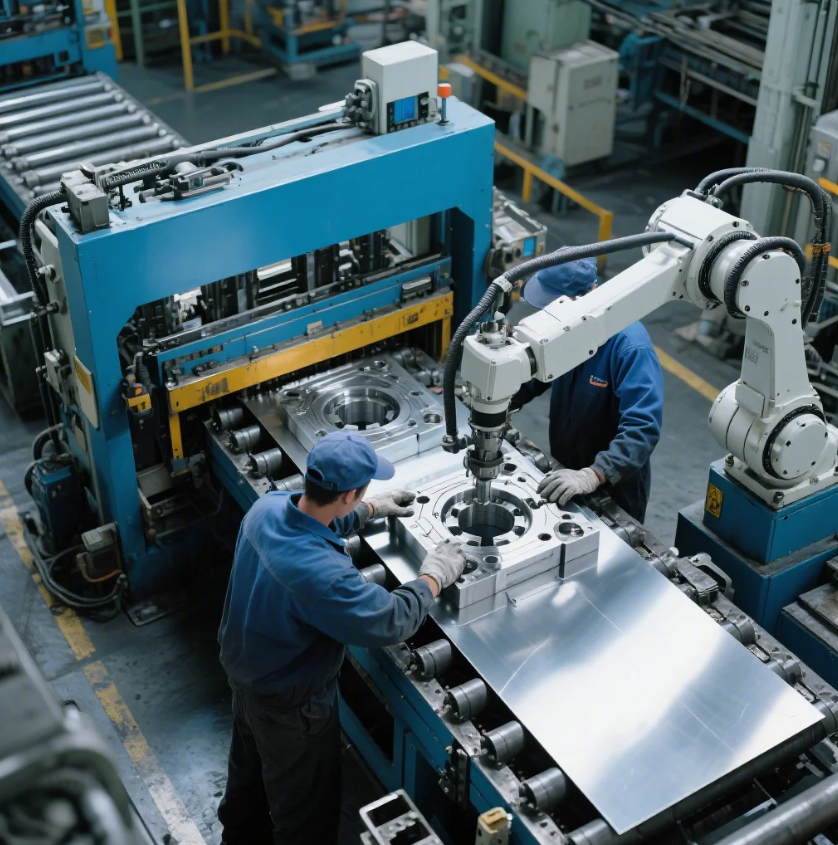

The four-step drawing process is a more detailed version of the general drawing process, typically used for creating deeper or more complex parts. These steps ensure that the material flows correctly during the drawing process and that the final part is formed without defects. Let’s explore the four steps involved in the drawing process:

- Blank Preparation: The first step in the four-step drawing process involves preparing the metal blank. The material is cut into the appropriate size and shape, ensuring it fits into the die. The blank’s dimensions are critical to ensure that the metal can be drawn without excessive thinning or tearing.

- Drawing: The second step is the actual drawing process, where the metal blank is pulled through a die by the punch press. The metal is stretched and shaped into the desired form, typically a cylindrical or cup-like shape.

- Redrawing (if necessary): If the initial drawing creates a shallow part, redrawing may be necessary to increase the depth. This process pulls the metal further through the die to achieve the required depth and smooth out the shape.

- Finishing: Once the drawing is complete, the part is finished by trimming off excess material, cleaning, and applying any necessary coatings. This step ensures that the part is free from defects and ready for use.

Snippet paragraph: The four-step drawing process includes blank preparation, drawing, redrawing (if needed), and finishing to ensure deep parts are created with precision.

Dive Deeper:

In more complex applications, the four-step drawing process is essential for creating parts that have specific depth and smooth contours. Each step is carefully controlled to ensure that the material is not overstretched, which could lead to thinning or tearing. Redrawing is particularly important in the production of deep-drawn parts, such as beverage cans or automotive components, as it allows the material to be shaped more precisely over multiple stages.

What is the definition of the process of drawing?

Drawing, in the context of metalworking, is the process of shaping a metal sheet by pulling it through a mold or die. It is a method used to create deeper shapes from a flat metal surface, such as cups, cans, and other hollow parts. The metal is stretched and deformed as it is drawn through the die, creating the desired shape. Drawing is used in a wide variety of industries, including automotive, packaging, and consumer goods.

Snippet paragraph: Drawing is a metalworking process that pulls a flat metal sheet through a die to create deep and complex parts. It’s used for parts like containers and automotive components.

Dive Deeper:

Drawing is one of the key forming processes in metalworking and is often used to create parts that require deep, intricate shapes. It is commonly employed for manufacturing hollow or cup-like parts, such as containers, cans, and automotive body panels. The process can be performed using various techniques, such as shallow drawing or deep drawing, depending on the complexity of the part and the depth required.

To achieve the desired outcome, it is crucial to control factors such as material flow, die design, and the amount of stretching that occurs during the process. This ensures that the part maintains its strength and structural integrity while taking on the desired shape.

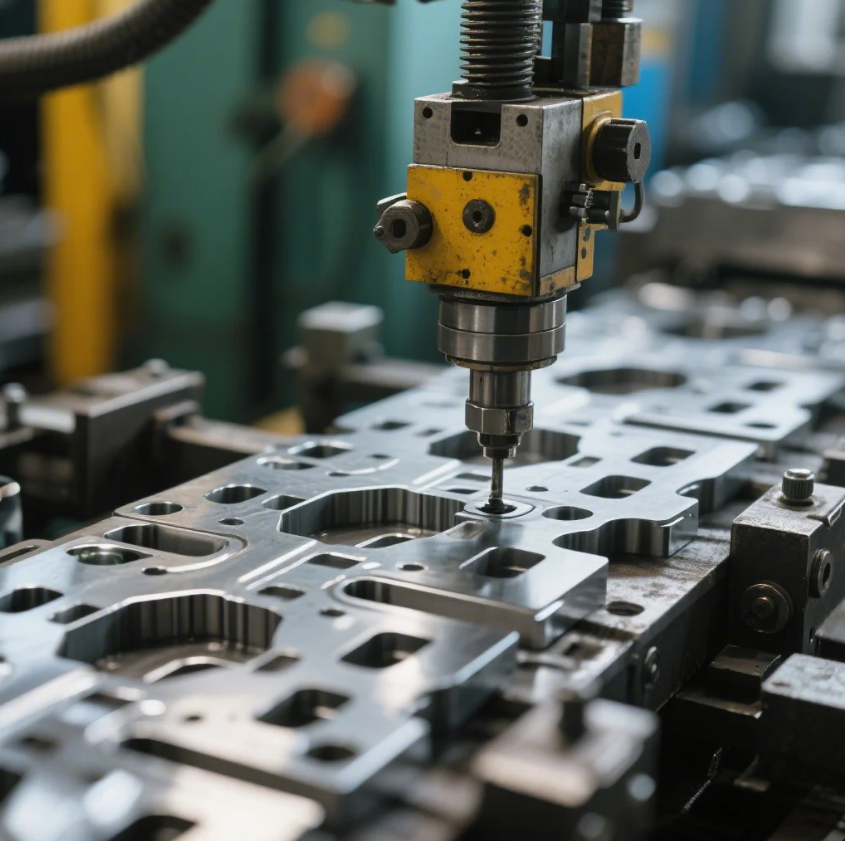

What is a draw method?

A draw method refers to the specific technique or process used to shape metal by pulling it through a die. The term "drawing" is commonly used to describe the method, and it is often performed in stages to achieve deep shapes or parts with intricate details. Drawing can be used to create both shallow and deep parts, and the method is employed in industries such as automotive manufacturing, packaging, and consumer electronics.

Snippet paragraph: A draw method is a technique used to pull metal through a die to create deep shapes, often employed in stages to ensure precision.

Dive Deeper:

There are various draw methods used in metalworking, each designed for different applications and part types:

- Shallow Drawing: Used to create parts with relatively shallow depths, such as trays or shallow cups. The metal is pulled through a die once to form the desired shape.

- Deep Drawing: This method involves drawing the metal through the die in multiple stages to create deeper parts like cans or containers. The material is stretched and shaped at each stage to achieve the required depth without weakening the metal.

- Multi-Stage Drawing: In some cases, multiple stages of drawing are required to achieve complex shapes. This method helps to maintain the structural integrity of the material while allowing for intricate designs.

Drawing methods vary depending on the material, the part’s shape, and the required depth. Understanding the right method to use is crucial for achieving the best results.

Conclusion

The draw process is an essential method in metalworking, allowing manufacturers to create deep and intricate parts from flat metal sheets. By understanding the steps involved, including blank preparation, drawing, redrawing, and finishing, manufacturers can ensure precision and quality in their parts. If you need high-quality drawn parts for your business, Prime offers expert solutions with fast delivery and superior craftsmanship. Reach out today to learn more about our drawing capabilities and request a quote!