What is the draw process of stamping?

The draw process is one of the most critical stages in the stamping method, used to create deep and complex shapes from flat metal sheets. This process involves pulling the metal through a die to form a specific shape, making it ideal for producing parts like cans, cups, and other deep, intricate components. In this article, we’ll explore what the draw process of stamping is, how it works, and the essential differences between drawing and other metalworking processes.

Snippet paragraph: The draw process of stamping pulls metal through a mold to create deep and complex shapes. It’s essential for producing parts like containers and cups.

Transition paragraph: Let’s dive deeper into how the draw process works and explore other related processes like stamping and forming.

What is the stamping procedure?

The stamping procedure refers to a series of operations used to shape and cut metal using a die and press. While the draw process is one of the key steps in stamping, the overall stamping procedure typically includes other stages such as blanking, punching, and bending. Each step is designed to progressively shape the raw metal into the desired final form.

Snippet paragraph: Stamping involves multiple steps like blanking, punching, bending, and drawing to shape metal into the desired part.

Dive Deeper:

The stamping procedure involves several key operations:

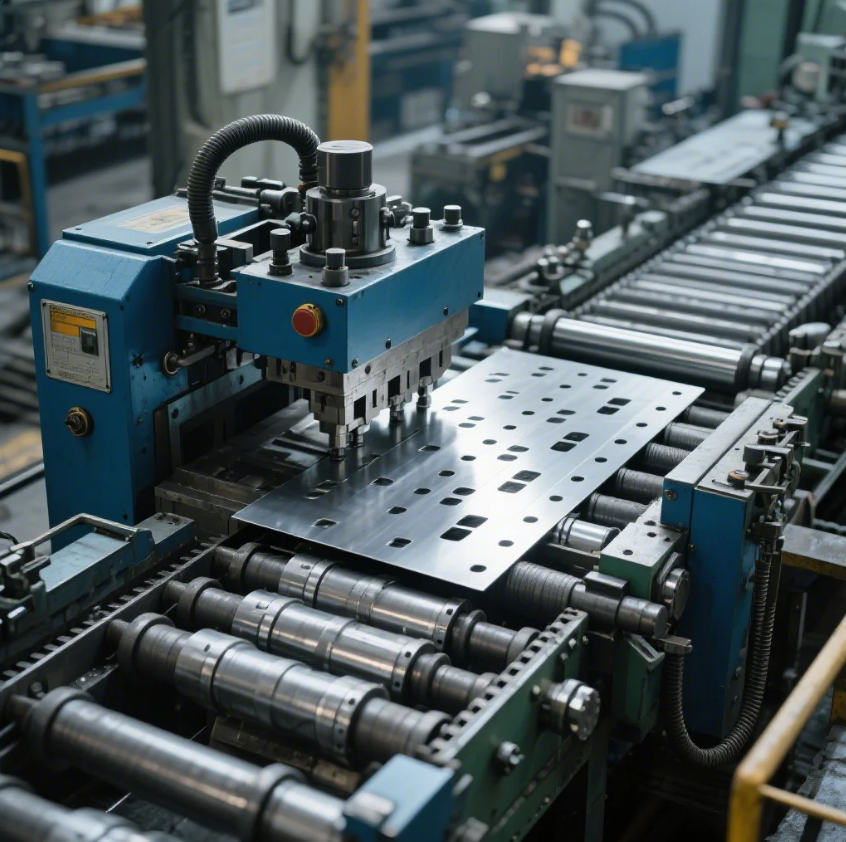

- Blanking: Cutting the raw metal sheet into blanks, which will serve as the base material for further processing.

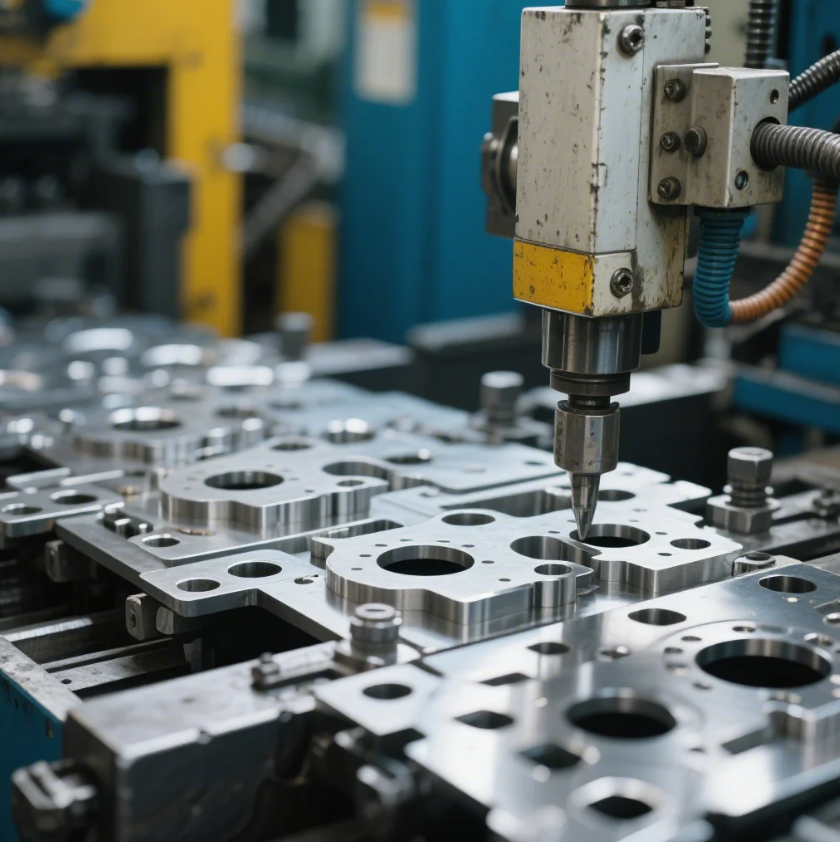

- Punching: Creating holes or cutouts in the blank using a punch press.

- Bending: Applying force to the metal to bend it at specific angles.

- Embossing: Creating raised patterns or designs on the metal surface.

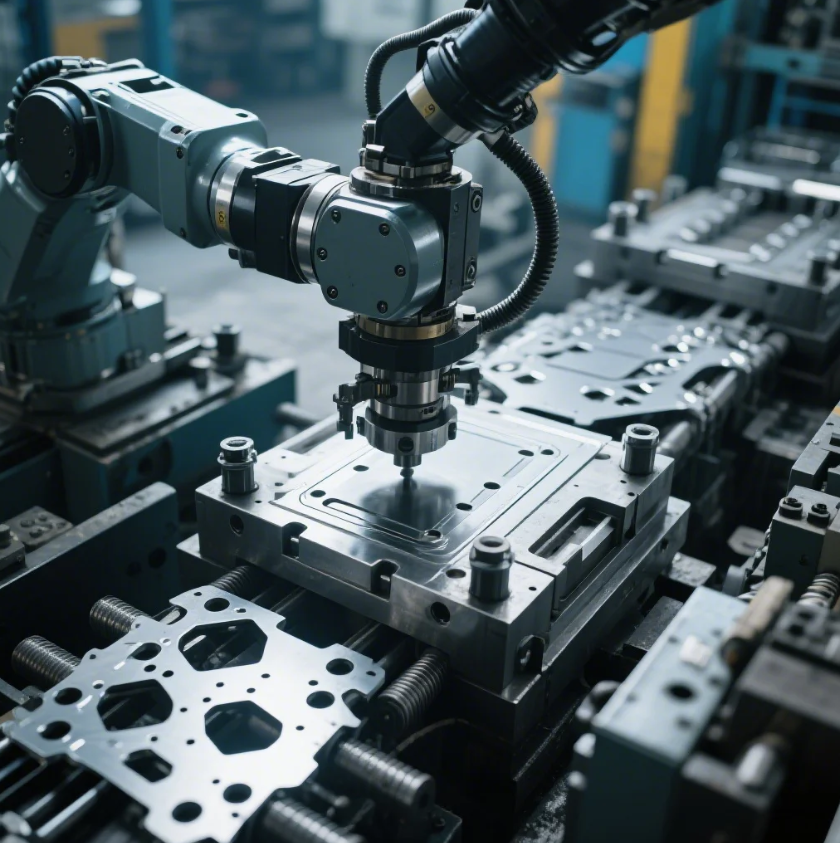

- Forming: Shaping the metal into three-dimensional shapes.

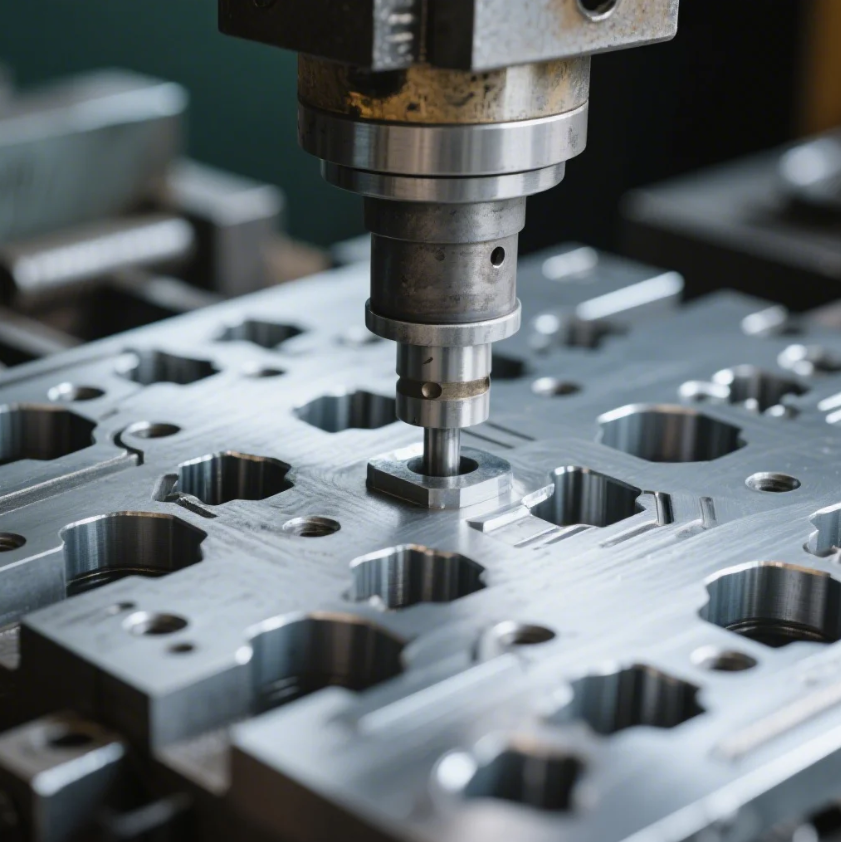

- Drawing: Using a die to pull the metal into a deep shape, such as a cup or container.

- Finishing: Trimming, cleaning, and coating the final part to ensure it meets the required specifications.

While the drawing process specifically focuses on creating deep shapes, it is typically followed by finishing steps to ensure the part is fully functional and aesthetically pleasing. These additional operations also add value to the product, ensuring that it meets both visual and functional requirements.

What is the difference between drawing and stamping?

Drawing and stamping are both key techniques in metalworking, but they have distinct differences in their applications and methods. Stamping is a broad term that includes a variety of operations, such as blanking, punching, and bending, whereas drawing specifically refers to the process of pulling metal into a mold to create deep shapes.

Snippet paragraph: Drawing is a specific stamping technique used to create deep shapes, while stamping includes a broader range of operations like punching and bending.

Dive Deeper:

While both drawing and stamping involve the use of dies and presses to shape metal, the primary difference lies in the final product’s complexity and depth:

-

Stamping is used for shaping, cutting, and forming metal into relatively shallow parts, such as simple cutouts, brackets, or panels. Stamping typically involves operations like blanking, punching, and bending.

-

Drawing, on the other hand, focuses on creating deep, complex shapes. The metal is pulled through a die, stretching the material to form shapes with higher depth, such as cups, cans, or other deep-drawn parts. Drawing is often used for parts that require a high degree of curvature or volume.

A good example of the difference is in creating a simple bracket (stamping) versus a deep, cylindrical part like a can (drawing). While both processes are forms of stamping, drawing requires more specialized equipment and controls. The process of pulling the material through the die demands close attention to material flow and thickness, and it often requires multiple stages to ensure the final product is formed correctly.

What is the difference between drawing and forming process?

Both drawing and forming are used to shape metal, but the techniques and the outcomes differ. Drawing specifically refers to the process of pulling the metal into a mold to create deep shapes, whereas forming is a broader term that encompasses a variety of methods used to shape metal into more complex or customized forms.

Snippet paragraph: Drawing is a specific type of forming used to create deep shapes, while forming includes various techniques to shape metal, such as bending or stretching.

Dive Deeper:

- Drawing: Drawing is a form of forming where the metal is pulled through a die to create deep, complex shapes. The process stretches the metal, which can result in thinning of the material, so careful control is necessary to avoid defects such as tearing or wrinkling. Deep-drawn parts, such as beverage cans or containers, are often produced using this method.

- Forming: Forming is a more general term used to describe the shaping of metal into a variety of configurations. Forming includes operations like bending, stretching, or pressing metal to produce parts with both shallow and complex geometries. While drawing is a form of forming, not all forming involves drawing. For example, bending or stamping a metal sheet is a type of forming that does not require the drawing process.

Key Difference:

The key difference lies in the depth and complexity of the parts. Drawing is primarily used for deep parts, while forming is a more general process that can create a variety of shapes, both deep and shallow. Forming can be as simple as bending a sheet of metal into a flat angle or as complex as stretching the metal into intricate designs. Both processes rely on precision and control to ensure the metal behaves as intended during each step.

What are the steps in stamping?

Stamping involves a variety of steps to shape and cut metal, each step playing a crucial role in achieving the final product’s precision and quality. The steps can vary slightly depending on the type of part being produced, but they generally follow a similar sequence:

- Blanking: Cutting the raw metal into a blank that will be used for further processing.

- Punching: Using a punch press to create holes or cutouts in the blank.

- Bending: Shaping the metal at specific angles to create the desired form.

- Embossing: Creating raised patterns or designs on the metal.

- Forming: Creating deeper, more complex shapes.

- Drawing: Pulling the metal into a mold to create deep shapes.

- Finishing: Trimming, cleaning, and coating the part to meet aesthetic and functional requirements.

Snippet paragraph: The stamping process involves blanking, punching, bending, embossing, forming, drawing, and finishing to shape the metal into the final part.

Dive Deeper:

Each of the stamping steps serves a distinct function:

- Blanking: Cutting the metal into the required shape.

- Punching: Adding holes, slots, or cutouts for functional purposes.

- Bending: Creating angles or curves in the metal.

- Embossing: Adding texture or raised patterns to the part.

- Forming: Creating deeper, more complex shapes.

- Drawing: Used specifically to create deep or curved parts.

- Finishing: Finalizing the part by cleaning, trimming, and adding protective coatings.

These steps work together to create high-quality stamped parts with the correct dimensions, surface finish, and functionality. The quality of each step affects the overall outcome, which is why it is essential to monitor each process closely to prevent defects and ensure precision.

Conclusion

The draw process of stamping is essential for creating deep, complex parts from flat metal sheets. Understanding the differences between drawing, stamping, and forming processes can help manufacturers choose the right technique for their needs. If you’re looking for high-quality stamped or drawn metal parts, Prime offers precision manufacturing with quick delivery and top-notch service. Our experience ensures that we can deliver custom solutions for your specific needs. Contact us today to get a quote and discuss your custom solutions!