What is the injection molding process?

Struggling to control plastic parts quality or understand how molding works?

Injection molding is a reliable way to mass-produce plastic parts with consistent precision. It involves heating, injecting, cooling, and ejecting. Learn each stage step-by-step to avoid costly defects.

You’re not alone if injection molding seems complicated at first. But once broken down, the process becomes easy to understand. Let’s walk through the key stages, explain the concepts, and show how Prime supports global clients with high-quality plastic parts and complete customization.

What is the injection molding process step by step?

Many buyers want perfect plastic parts but don’t know how they’re made. That uncertainty causes delays and quality issues.

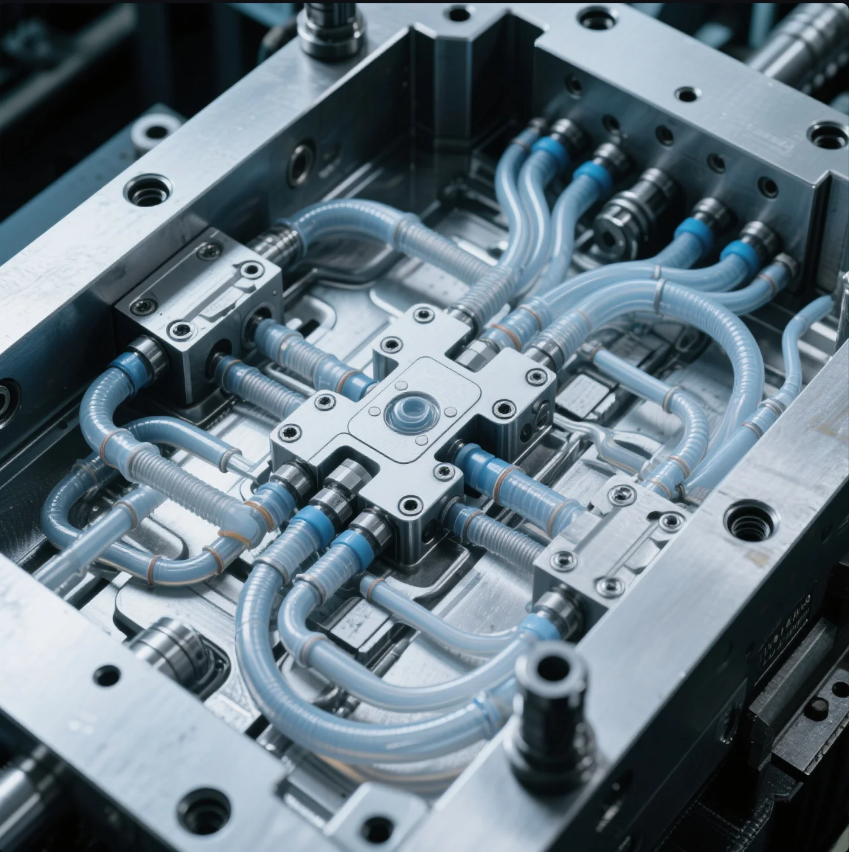

Injection molding includes six steps: clamping, injection, dwelling, cooling, mold opening, and ejection. Each stage requires precise timing.

Step-by-step Breakdown of Injection Molding

| Step | Description |

|---|---|

| 1. Clamping | Mold halves are closed tightly to prepare for injection. |

| 2. Injection | Melted plastic is injected into the mold cavity under high pressure. |

| 3. Dwelling | Pressure is maintained to ensure the mold fills completely. |

| 4. Cooling | Plastic inside the mold cools and solidifies into shape. |

| 5. Mold Opening | Mold halves open once the part is solidified. |

| 6. Ejection | The finished part is pushed out by ejector pins. |

Every step must stay on schedule. Any deviation may cause defects like warping or bubbles. At Prime, our ISO-certified systems and automated lines ensure stability and consistency.

Learn more about our plastic parts customization services →

What is the explanation of injection moulding process?

Most people know injection molding produces plastic parts. But few understand how the internal process works.

Injection molding is a fast and accurate method that injects melted plastic into a mold to create parts.

Why Injection Molding is Ideal for Custom Plastic Parts

Injection molding provides speed, repeatability, and low cost per part—ideal for industrial components and OEM applications.

| Feature | Benefit |

|---|---|

| High precision | Shapes with tight tolerances ±0.01mm |

| Fast cycle | Each part can be produced within seconds |

| Low waste | Scrap plastic is recyclable |

| Consistency | Excellent for bulk production |

Our engineers at Prime collaborate with clients for mold design, DFM analysis, and sampling. This ensures smoother production with fewer surprises.

Visit our plastic solutions homepage →

What are the 4 stages of injection molding?

Many buyers get confused by the terminology of molding stages.

The four core stages are plastication, injection, cooling, and ejection. Each one directly impacts part quality.

How Each Stage Affects Final Quality

Understanding each stage helps prevent defects and improves sourcing decisions.

1. Plastication

Plastic pellets melt inside the machine’s barrel. Melt temperature must stay stable.

2. Injection

Plastic is injected into the mold cavity. Injection speed and pressure must be balanced.

3. Cooling

The mold cools the plastic. Inconsistent cooling causes warping or shrinkage.

4. Ejection

Ejector pins push the part out. Poor ejection can damage edges or surfaces.

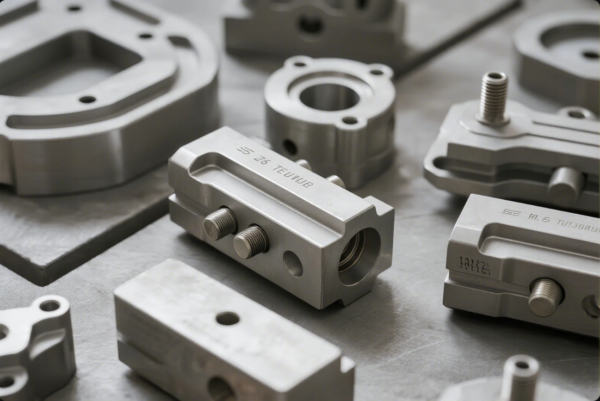

At Prime, we calibrate each machine for stable temperatures and pressure. This is why global clients trust us as an ISO-certified injection molding supplier.

Check our metal stamping & injection capabilities →

Is injection molding a hard job?

Some buyers think molding is labor-heavy and difficult to control. That’s outdated.

Modern injection molding is automated and monitored digitally. Skilled operators focus on system settings, not manual work.

Modern Molding is Smart, Not Manual

Injection molding today uses sensors, real-time data, and robotic handling.

| Role | Responsibility |

|---|---|

| Technician | Programs and adjusts molding machines |

| Engineer | Designs mold and configures cycles |

| Inspector | Checks samples and records defects |

At Prime, our 24/7 automated lines handle high-volume production for clients in the US, Europe, and the Middle East. This means faster delivery and fewer delays—even during peak seasons.

Visit Prime’s certified manufacturing lines →

Conclusion

Injection molding produces plastic parts with speed, accuracy, and repeatability across all industries.

Need a reliable partner for your next injection molding project?

Contact Prime today at https://primecustomparts.com/ or https://primecustomparts.com for a free quote, expert consultation, and tailored plastic part solutions. We deliver fast, pack securely, and meet global quality standards. Partner with us to avoid costly mistakes and ensure your parts arrive perfect—every time.

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com