What is the lifespan of an injection mold?

Curious about how long an injection mold really lasts?

The average lifespan of an injection mold ranges from 10,000 to over 1 million cycles, depending on material, mold care, part complexity, and production conditions.

Understanding mold lifespan is key for budgeting, planning tooling investments, and maintaining consistent product quality. In this guide, we’ll explore how long injection molds last, how many cycles they can handle, how long molded parts hold their shape, and what to do with molds after they retire.

How long do injection molds last?

This is one of the most important questions for buyers, engineers, and OEMs managing product lifecycles.

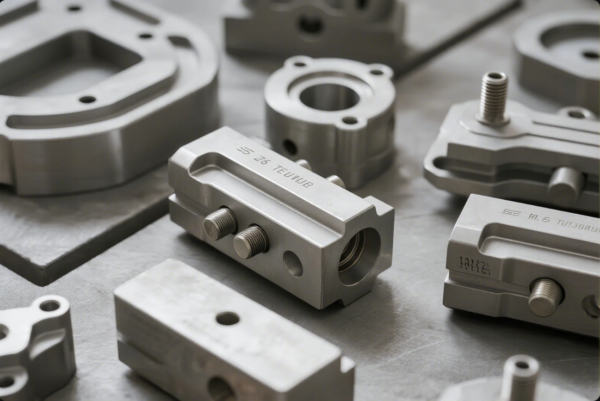

A high-quality injection mold made from hardened steel can last over 1 million cycles, while aluminum molds may last 10,000 to 100,000 cycles depending on maintenance and material.

Mold Longevity by Tool Material

| Mold Material | Average Lifespan (Shots) | Typical Application |

|---|---|---|

| Aluminum | 10,000–100,000 | Prototyping, low-volume runs |

| P20 Pre-hardened Steel | 100,000–500,000 | Medium-volume production |

| H13 or S136 Hardened Steel | 500,000–1,500,000+ | Automotive, consumer electronics |

At Prime, we recommend choosing tooling based on your volume goals. For a one-time batch under 50,000 units, aluminum is fast and affordable. For mass production, we build hardened steel molds designed for durability and repeatability.

Learn about Prime’s mold construction options →

How many times can an injection mold be used?

If you’re investing in custom tooling, this is the question that determines ROI.

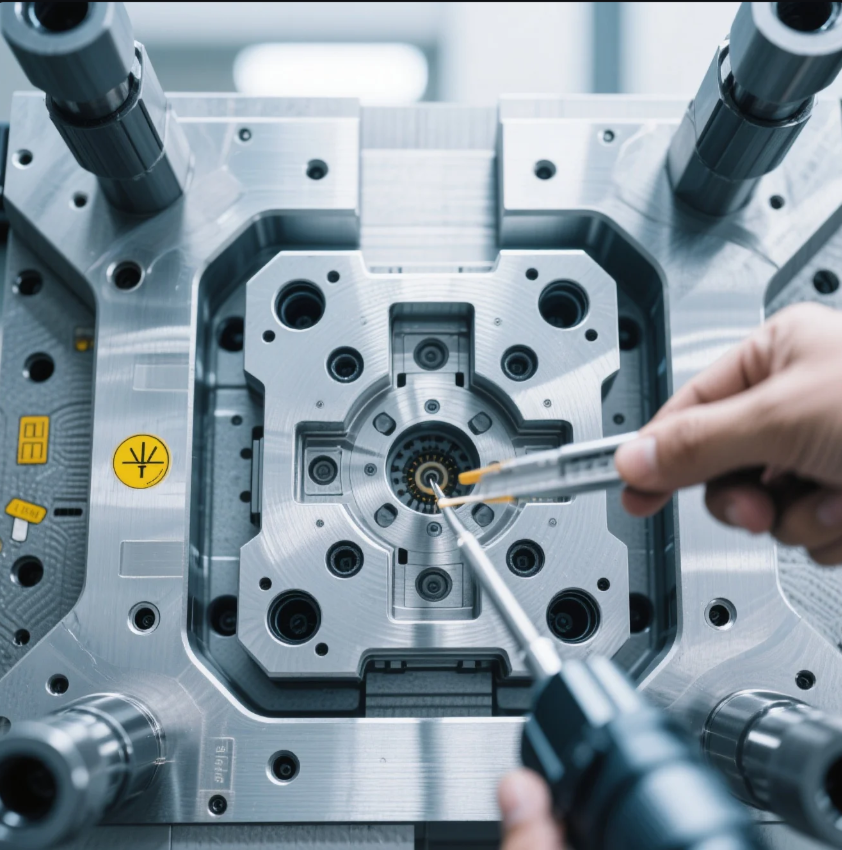

Most steel injection molds can be used for hundreds of thousands to millions of cycles when maintained properly. Even after heavy use, molds can often be reconditioned to extend lifespan.

Factors That Influence Reusability

- Resin Type: Abrasive materials (e.g., glass-filled nylon) wear molds faster

- Part Complexity: Thin walls, undercuts, or deep cores accelerate tool fatigue

- Cooling System: Efficient cooling extends life by reducing thermal stress

- Maintenance: Regular cleaning and lubrication prevent premature wear

- Cycle Management: Avoiding over-pressurization reduces mechanical stress

At Prime, we provide lifetime shot tracking and preventive maintenance for long-term projects. We also re-polish or replace worn inserts when tolerances start to drift after 500,000+ cycles.

Ask about Prime’s tooling maintenance plans →

What happens to old injection molds?

Eventually, every mold reaches the end of its life—but that doesn’t mean it gets tossed immediately.

Old molds are typically stored, refurbished, recycled, or disassembled. Decisions depend on the mold condition, future production plans, and material value.

Common Paths for Aging Molds

| Outcome | Description |

|---|---|

| Refurbishment | Damaged cores or gates are rebuilt for another production cycle |

| Archive Storage | Molds preserved with anti-rust treatments for future reorders |

| Disassembly | Usable components salvaged; others scrapped |

| Recycling | Steel/aluminum sold for material recovery or remanufactured into jigs/tools |

At Prime, molds remain customer property unless otherwise specified. We offer long-term mold warehousing and alert clients when molds approach the end of their usable life.

Explore Prime’s mold storage and reactivation services →

How long does injection moulding hold?

Buyers also ask: once a part is molded, how long will it hold its shape or structural performance?

Properly molded thermoplastic parts maintain their dimensional stability and mechanical performance for years, depending on the material, environment, and application.

What Affects Long-Term Part Performance?

| Factor | Impact on Molded Part Hold Time |

|---|---|

| Resin selection | UV- and heat-stable plastics hold shape longer |

| Environment | Humidity and temperature accelerate warping or aging |

| Load and stress | Constant mechanical load may lead to creep |

| Additives and fillers | Improve strength, stability, or flame resistance |

| Mold quality | Poor mold finish can cause stress concentration |

At Prime, we select materials for long-term dimensional hold based on your end-use needs—whether indoors, outdoors, exposed to heat, or under continuous load.

Request a resin recommendation for long-term use →

Conclusion

The lifespan of an injection mold can range from a few thousand to over a million cycles. With proper care, most molds last for years, making them one of the most valuable investments in plastic part production.

Need help evaluating your existing molds or planning new tooling?

Contact Prime today at https://primecustomparts.com or https://primecustomparts.com to request a mold condition report, refurbishment quote, or tooling strategy review. Whether you need short-run tooling or million-shot capacity, we’ve got you covered.

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com