What is the most common injection molded plastic?

Trying to choose the right plastic for your injection molded product?

Polypropylene (PP) is the most commonly used plastic in injection molding due to its low cost, excellent chemical resistance, and versatility. Other popular choices include ABS, polyethylene (PE), polystyrene (PS), and nylon.

Selecting the correct plastic is one of the most important decisions in any injection molding project. In this guide, we’ll walk you through the most commonly used resins, their properties, and how to decide between the cheapest, best, or strongest plastic depending on your needs.

What is the most common plastic used in injection molding?

If you’re launching a new plastic part, your material choice will define cost, durability, and performance.

Polypropylene (PP) is the most widely used plastic for injection molding worldwide. It’s affordable, chemically resistant, and suitable for a wide range of applications.

Why Polypropylene Is So Popular

| Property | Advantage |

|---|---|

| Low melting point | Reduces cycle time and energy usage |

| Chemical resistance | Ideal for food, chemical, and medical parts |

| Flexibility | Suitable for living hinges and soft components |

| Cost | Lower than most engineering plastics |

At Prime, over 40% of our high-volume molded parts use PP due to its balanced performance and cost-effectiveness. Whether you’re making packaging, automotive clips, or containers, PP is often the default starting point.

Explore Prime’s material portfolio →

What is the cheapest plastic for injection molding?

Cost plays a key role in large-scale production. But cheapest doesn’t always mean best for function.

Polystyrene (PS) and polyethylene (PE) are among the cheapest plastics for injection molding. They’re ideal for basic applications where aesthetics and strength are not critical.

When to Use Low-Cost Plastics

| Material | Advantages | Common Uses |

|---|---|---|

| Polystyrene | Very cheap, easy to mold | Toys, disposable products |

| Polyethylene | Good chemical resistance, flexible | Bottles, containers, bags |

| Polypropylene | Low cost with better toughness | Packaging, caps, automotive |

If your product needs to meet strict functional or regulatory requirements, low-cost resins might not be enough. At Prime, we guide clients through cost-performance trade-offs to help them choose smarter.

Request a cost comparison of common plastics →

What is the best plastic for injection molding?

There’s no one-size-fits-all answer. “Best” depends on your part’s function, environment, and performance requirements.

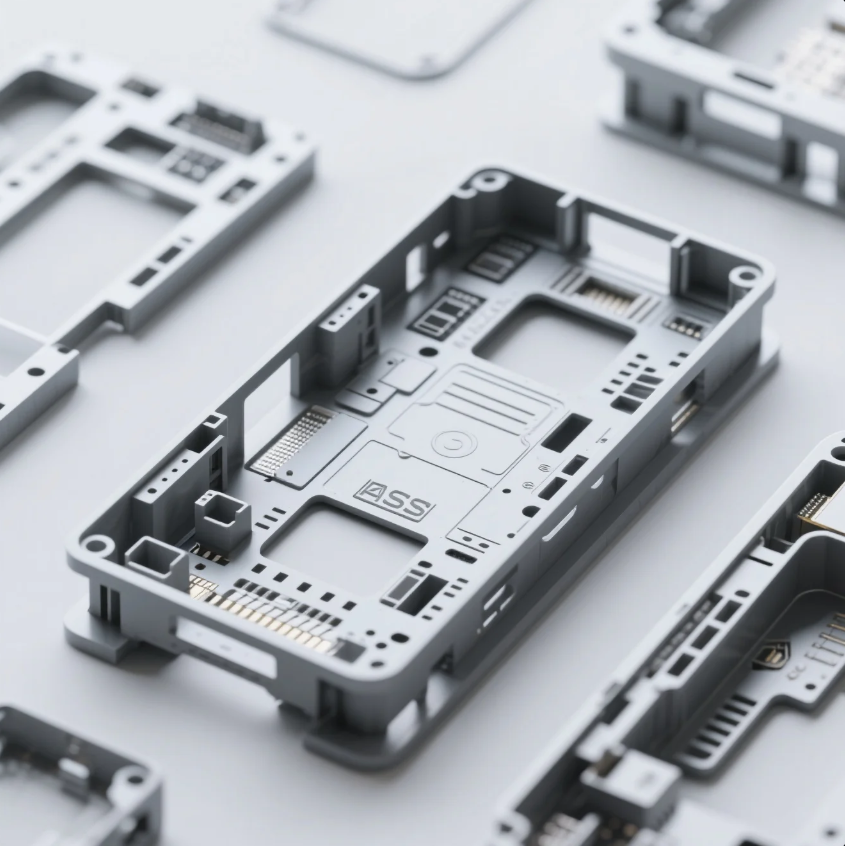

ABS (Acrylonitrile Butadiene Styrene) is often considered the best all-around plastic for injection molding due to its strength, surface finish, and ease of processing.

ABS vs Other Versatile Plastics

| Plastic | Strength | Finish Quality | Cost | Typical Use |

|---|---|---|---|---|

| ABS | Medium | Excellent | Moderate | Electronics, appliances |

| PC (Polycarbonate) | High | High | High | Safety lenses, high-impact parts |

| Nylon (PA) | High | Medium | Moderate | Gears, connectors, structural |

| POM (Acetal) | High | Smooth | Moderate | Bearings, sliding components |

At Prime, we match every project to the ideal plastic, factoring in durability, appearance, and end-use stress. If your part needs high strength, heat resistance, or regulatory compliance, we’ll recommend the right technical-grade resin.

Get help selecting the best plastic →

What is the strongest injection molded plastic?

Strength matters most in load-bearing, impact-resistant, or structural components.

Glass-filled nylon (PA-GF) and polycarbonate (PC) are among the strongest plastics for injection molding. These materials offer high tensile strength, rigidity, and fatigue resistance.

Comparison of Strong Plastics

| Material | Tensile Strength (MPa) | Features |

|---|---|---|

| PA66-GF (Glass-filled Nylon) | 150–200 | Very stiff, excellent load handling |

| PC (Polycarbonate) | 60–70 | Tough, impact-resistant, transparent |

| PEEK | 90–100 | High-performance, chemical resistant |

| PPS (Polyphenylene Sulfide) | 90–120 | Excellent thermal stability |

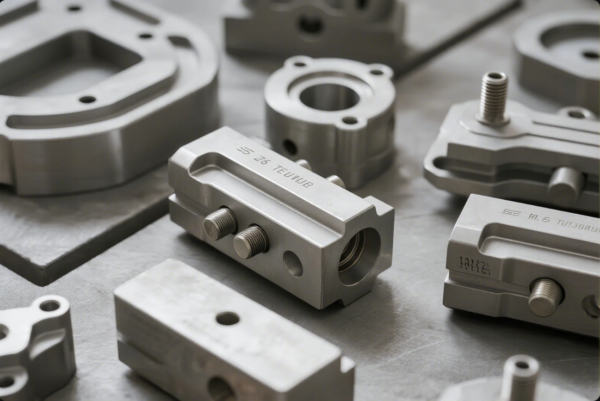

High-strength plastics are often used in automotive, aerospace, and industrial applications. At Prime, we mold precision-engineered parts using reinforced materials that meet even the most demanding specs.

Learn more about Prime’s high-performance plastics →

Conclusion

Polypropylene is the most common injection molded plastic for its cost and versatility. But depending on your needs, ABS, PC, or glass-filled nylon might be a better fit for performance or durability.

Need help choosing the right plastic for your next project?

Contact Prime today at https://primecustomparts.com or https://primecustomparts.com to discuss your part design, functional needs, and material options. We’ll recommend the most cost-effective and reliable resin—and deliver it fast, with certified quality.

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com