What is the process of deep draw stamping?

Buyer: I’m reviewing some enclosure designs and saw “deep drawn housing” mentioned. What exactly is deep draw stamping?

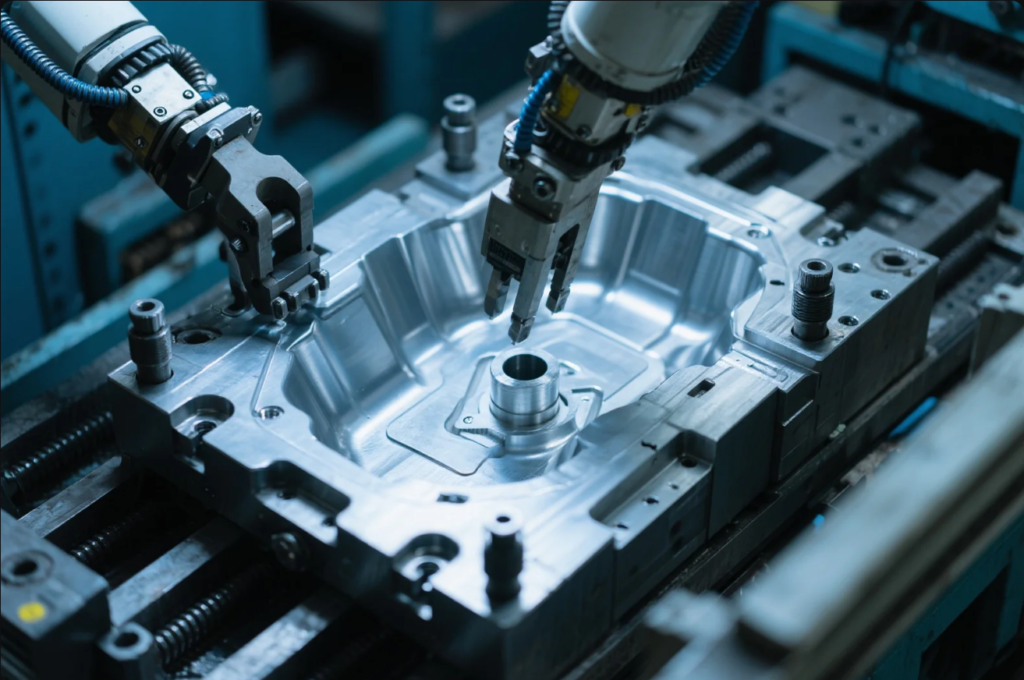

Engineer (Prime): Great question. Deep draw stamping is a forming process that stretches a flat sheet of metal into a deep, hollow shape using a punch and die—without breaking or thinning the wall too much. It’s used when you need depth greater than the sheet’s diameter.

What is the deep draw forming process?

Buyer: So how does deep draw work compared to regular pressing?

Engineer: Deep drawing uses:

- A punch to push the metal

- A die cavity to shape the part

- A blank holder to control material flow

The goal is to form a part that’s deeper than its diameter, like cans, motor housings, or sinks.

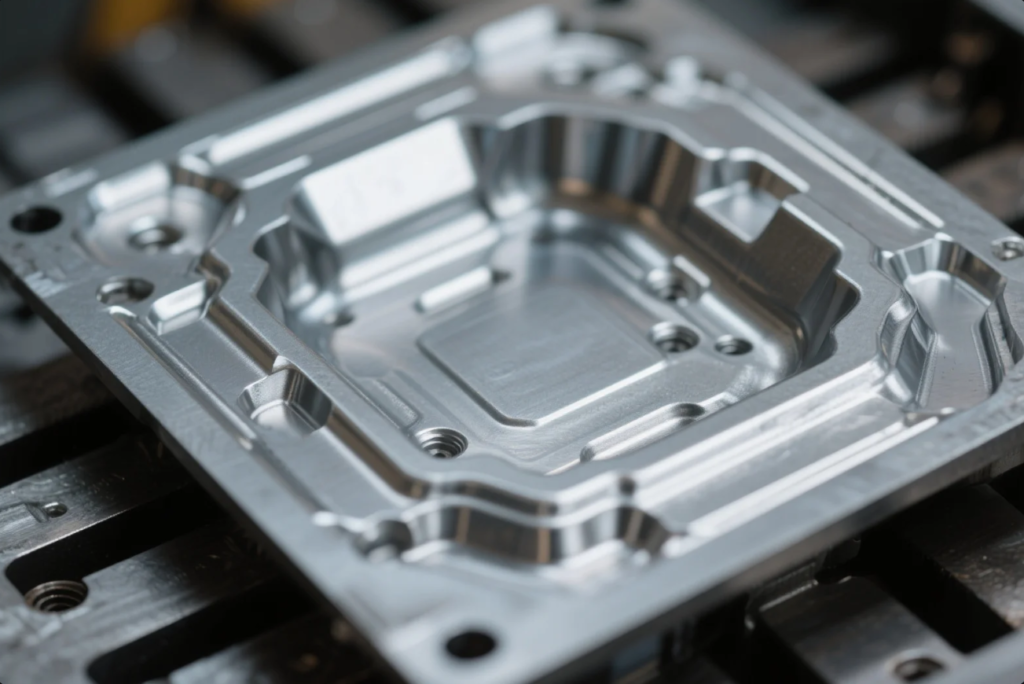

Key Characteristics

| Parameter | Deep Drawing Value |

|---|---|

| Depth-to-width | Greater than 0.5:1 |

| Material type | Soft metals: aluminum, brass, steel |

| Wall thickness | Mostly uniform, slight thinning |

| Common tolerance | ±0.1–0.3 mm |

At Prime, we run progressive or multi-stage deep draw operations depending on the final shape.

Summary: Deep drawing transforms flat blanks into seamless, hollow shapes without welding or joints.

What are the 7 steps in the stamping method?

Buyer: Is deep drawing just one step in stamping?

Engineer: It can be, but often deep drawn parts go through multiple stamping stages. The typical process includes:

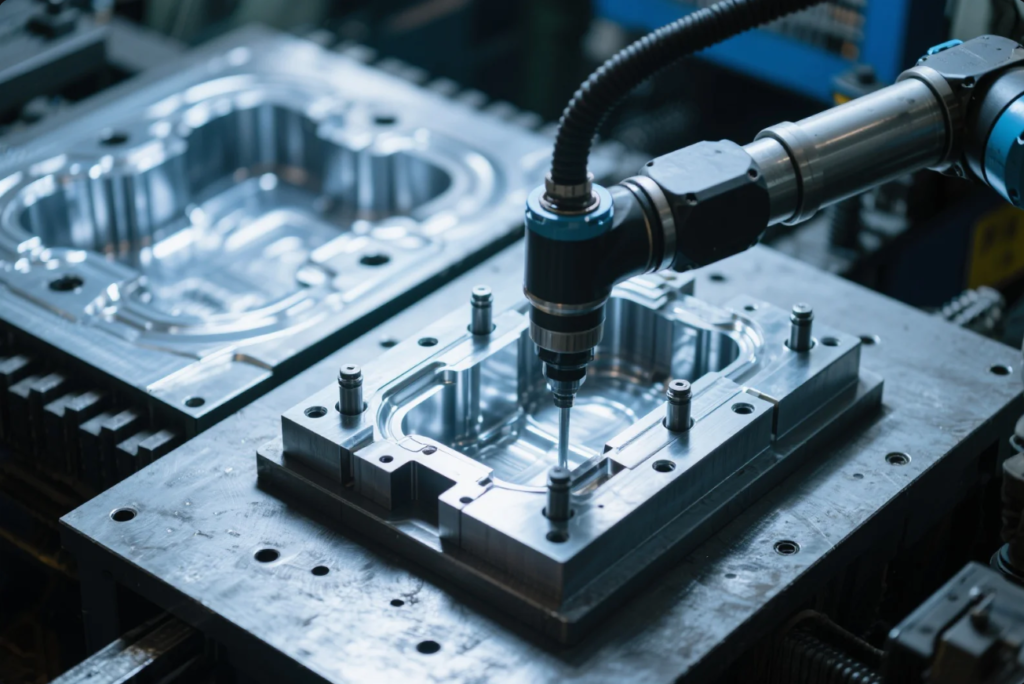

- Blanking – Cutting the flat disk (blank) from a sheet

- Drawing – Forming the initial cup shape

- Redrawing – Deepening the shape through additional punches

- Trimming – Removing excess flange material

- Ironing – Making walls more uniform in thickness

- Piercing – Adding holes, slots, or openings

- Flanging or Curling – Folding the rim or reinforcing the edge

Prime Tip: We use compound or progressive dies to combine steps and lower cost.

Summary: Most deep drawn parts go through 5–7 stamping stages for full shape and function.

What is the draw process of stamping?

Buyer: What exactly is the “draw” part in all this?

Engineer: “Drawing” means pulling the material into the die cavity using a downward punch. The metal flows inward radially and downward axially—creating a deep shape.

- First draw forms the base

- Redraws continue to deepen without cracks

- Lubrication is critical to reduce friction and tearing

- Radius design helps prevent wrinkling or splits

At Prime, we optimize draw ratios and corner radii for each metal type.

Summary: Drawing is the controlled deformation of flat metal into deep forms—step by step.

What is the difference between deep draw and stamping?

Buyer: So deep draw is a kind of stamping?

Engineer: Exactly. Here’s how they differ:

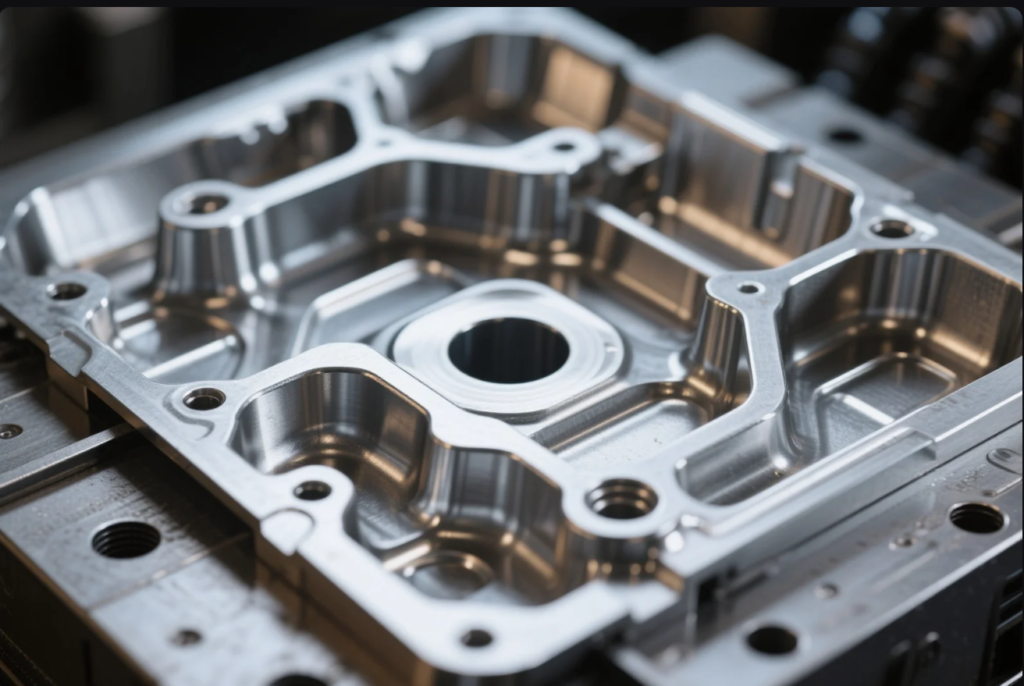

| Process | Max Depth | Use Case | Tools Used |

|---|---|---|---|

| Stamping | Shallow | Covers, brackets, panels | Die, press, punches |

| Deep Drawing | Deep | Cans, tanks, enclosures | Punch + die + blank holder |

Stamping includes blanking, piercing, and shallow forming. Deep draw is specifically for high-depth hollow parts that need seamless sides and tight tolerance.

Summary: Deep drawing is a subset of stamping—focused on depth and seamless hollow forms.

Frequently Asked Questions (FAQ)

❓ What materials are best for deep drawing?

Engineer: Aluminum, stainless steel (304/316), low-carbon steel, and brass—due to ductility.

❓ What’s the max depth you can draw?

Engineer: Typically up to 5× the part diameter using multiple stages.

❓ What’s the minimum wall thickness?

Engineer: It varies by metal, but we usually aim for 80–100% of original sheet thickness.

❓ Can Prime make custom deep draw dies?

Engineer: Yes. We design and produce tooling in-house under NDA, with full prototyping.

Conclusion

Buyer: So deep draw stamping is how we make those seamless deep parts?

Engineer: Exactly. If you need durable, leak-proof, or visually clean housings, deep draw is the way to go. At Prime, we help clients go from CAD → tooling → production with full technical support.

Buyer: Great. I’ll send my enclosure drawings for review.

Engineer: Perfect. We’ll run a draw ratio check and quote a prototype + production batch.

Need help with custom deep drawn parts or progressive stamping design?

Contact Prime for free DFM support, tooling consultation, and ISO-certified production.

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com