What Scrap Metal Is Good for Knife Making?

Scrap metal can be a great resource for knife making, as long as you know what types of metal are suitable for forging into a high-quality blade. While certain metals work better than others, blacksmiths and knife makers have been using recycled metals for centuries, often finding hidden potential in materials that would otherwise be discarded. In this article, we’ll explore which scrap metals are best for making knives, as well as the types of metals typically used in high-quality knife production.

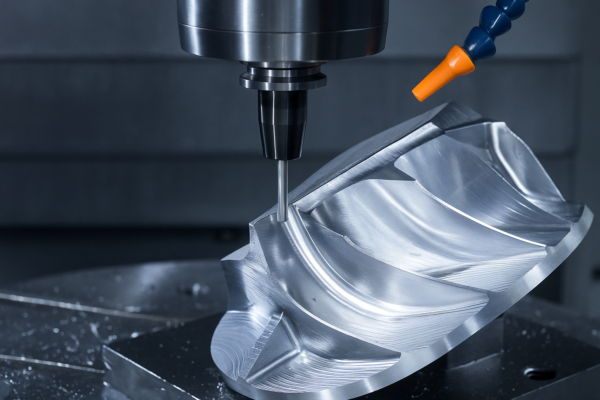

Snippet paragraph: Recycled scrap metal, such as old tools, automotive parts, and machinery steel, can be repurposed into high-quality knives with proper heat treatment and shaping.

Let’s explore the best types of scrap metal for knife making and what makes them suitable for creating blades.

What Is the Best Metal to Make Knives Out Of?

The best metal for making knives depends on its hardness, edge retention, and corrosion resistance. In general, the ideal metals for making knives are high-carbon steels, stainless steels, and tool steels. These metals offer the balance of strength, sharpness, and durability required for a high-performance blade.

Best Metals for Knife Making:

- High-Carbon Steel: 1095 and 5160 are popular high-carbon steels used in knife making. They are easy to harden and maintain sharp edges, making them perfect for durable, functional knives.

- Stainless Steel: 440C, S30V, and VG-10 are commonly used for knives that require corrosion resistance. While stainless steel can be harder to sharpen, it offers excellent performance in harsh environments.

- Tool Steel: D2, A2, and O1 steels are used in knives that need to maintain their sharpness and toughness under heavy use. Tool steels provide great edge retention and are often used for tactical knives and cutting tools.

Good Scrap Metals for Knife Making:

- Old Tools: Many old wrenches, files, or blades made from high-carbon or tool steel can be repurposed into knife blades.

- Automotive Parts: Steel parts like leaf springs or coil springs are often made from high-carbon steel and can be forged into high-quality knives.

- Machinery Parts: Parts made from tool steel or other alloys from machinery can be melted down or repurposed for forging blades.

Scrap metal that comes from tools or vehicles is often an excellent source for knife making because these metals are already designed to withstand heavy use, making them ideal for forging high-performance blades.

What Metal Is Used to Make High-Quality Knife Blades?

High-quality knife blades are typically made from carbon steel or stainless steel, with certain alloys added for improved performance. The right metal choice depends on the intended use of the knife, such as edge retention, toughness, or corrosion resistance.

Metals Used for High-Quality Knife Blades:

- High-Carbon Steel: 1095 and W2 are popular for knives requiring sharpness and edge retention. These metals can be hardened easily and hold a strong edge.

- Stainless Steel: S30V, S35VN, and 440C are commonly used in high-quality knives, as they offer a great balance of toughness, sharpness, and corrosion resistance. These metals are ideal for kitchen knives and knives used in wet or humid environments.

- Tool Steel: D2 and A2 steels are known for their durability and edge retention. Tool steels are often used for tactical knives and utility knives that require exceptional performance under stress.

While stainless steel offers corrosion resistance, high-carbon steel is prized for edge retention. A mix of these materials is often ideal for creating high-quality knife blades.

What Are the 3 Types of Metal Normally Used to Produce a Kitchen Knife?

Kitchen knives are often made from three main types of metal that balance sharpness, edge retention, and resistance to corrosion. These metals are designed to maintain a sharp edge and resist the corrosive effects of moisture and acids commonly found in kitchen environments.

Three Types of Metal for Kitchen Knives:

- Stainless Steel: Stainless steel is commonly used in kitchen knives due to its corrosion resistance and easy maintenance. Popular grades like 440C, VG-10, and S30V offer a good balance of sharpness and resistance to rust.

- High-Carbon Steel: High-carbon steels like 1095 and W2 are popular for kitchen knives that require exceptional sharpness and edge retention. These steels can rust if not maintained, but they can be easily sharpened and hold a cutting edge for a long time.

- Damascus Steel: Damascus steel is a type of steel that combines layers of carbon steel and stainless steel, creating a beautiful, strong, and durable blade. It’s often used for high-end kitchen knives due to its aesthetic appeal and edge retention.

Stainless steel is the most common metal for kitchen knives because of its resistance to corrosion, but high-carbon steel is favored by those who prioritize a sharper edge. Damascus steel offers both beauty and performance.

Is 1095 Steel Good for Knife Making?

Yes, 1095 steel is an excellent choice for knife making. It is a high-carbon steel that is well-known for its ability to hold a sharp edge. 1095 is a relatively affordable steel and is commonly used for forging knives, particularly for tactical knives, swords, and camping knives.

Advantages of 1095 Steel:

- Edge Retention: 1095 steel holds a sharp edge well, making it a great choice for knives that require precision cutting.

- Ease of Sharpening: It is relatively easy to sharpen compared to some stainless steels, making it ideal for users who need to maintain their knives regularly.

- Toughness: While 1095 steel is not as resistant to rust as stainless steel, it is tough and durable, performing well in high-stress applications.

However, 1095 steel requires regular maintenance (such as oiling the blade) to prevent rusting. It’s a fantastic choice for knives that need to be sharp and tough but will need a little more care than stainless steel blades.

Conclusion

When making knives, scrap metal from old tools, automotive parts, and machinery can be great sources of high-quality steel for forging blades. The best metals for knife making are high-carbon steels like 1095, stainless steels like S30V, and tool steels like D2. 1095 steel is a popular choice for tactical knives and utility blades due to its edge retention and sharpening ease, but it requires care to prevent rusting. For kitchen knives, stainless steel offers corrosion resistance, while high-carbon steel is chosen for superior sharpness and edge retention. Whether you’re using recycled metal or premium alloys, the right material will ensure you create a strong, durable, and sharp blade. For professional knife-making services or high-quality blades, contact Prime today for custom solutions.