Which Metal Cannot Be Used to Harden Steel?

When it comes to hardening steel, certain metals can improve the hardness and durability of the material, but not all metals are capable of undergoing hardening processes. Some metals simply cannot be hardened due to their chemical composition or lack of necessary properties. In this article, we’ll explore which metals can and cannot be used to harden steel and dive into common steel alloys like 1018 steel and stainless steel.

Snippet paragraph: Some metals, like lead and copper, cannot be hardened because they lack the necessary crystalline structure or carbon content to undergo heat treatment.

Let’s take a closer look at the metals that cannot be used to harden steel and how they compare to other materials.

What Metal Cannot Be Hardened?

Certain metals simply cannot be hardened, primarily due to their composition or the lack of carbon, which is critical for hardening steel. Hardening generally involves heating the metal and then quenching it to lock in the hardness.

Metals That Cannot Be Hardened:

- Lead: Lead is a soft, malleable metal that lacks the crystalline structure needed for hardening. It cannot undergo heat treatments to make it harder.

- Copper: Like lead, copper is soft and does not have the necessary properties to be hardened through traditional heat treatment methods.

- Zinc: Zinc is another metal that cannot be hardened. It is soft and has a low melting point, which makes it unsuitable for hardening processes.

Metals like lead and copper are used in applications where softness and malleability are preferred, but they cannot achieve the hardness required for heavy-duty applications like tooling or structural components.

Can I Harden Stainless Steel?

Yes, stainless steel can be hardened, but the process is slightly different from hardening carbon steel. Stainless steel contains a higher percentage of chromium and other alloying elements, which provide corrosion resistance but can make it more challenging to harden.

Hardening Stainless Steel:

- Martensitic Stainless Steel: Types like AISI 410, AISI 420, and AISI 440C are hardenable stainless steels and can undergo traditional hardening processes like quenching and tempering.

- Austenitic Stainless Steel: Stainless steels like AISI 304 or AISI 316 are not easily hardened by heat treatment because they have a face-centered cubic (FCC) crystal structure, which does not form martensite easily. These types of stainless steel require cold working to harden.

While stainless steel can be hardened, achieving the right hardness and strength depends on the type of stainless steel and the proper heat treatment process.

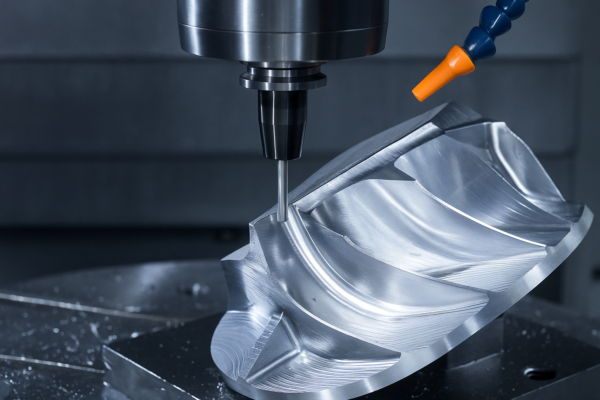

Can 1018 Steel Be Hardened?

1018 steel, a low-carbon steel, can be hardened to some extent, but it doesn’t achieve the same high hardness levels as higher-carbon steels. 1018 steel has a carbon content of around 0.18%, which makes it more suitable for processes that require toughness and ductility rather than extreme hardness.

Hardening 1018 Steel:

- Mild Hardening: 1018 steel can be hardened by heating it to a temperature around 1,500°F (815°C) and then quenching it, but the resulting hardness is relatively low compared to higher-carbon steels.

- Limited Hardening: While it can be hardened, 1018 is typically used for parts that require good machinability, toughness, and low-cost manufacturing rather than extreme hardness.

For applications requiring higher hardness, 1045 or 1095 steel, which have higher carbon content, would be better options.

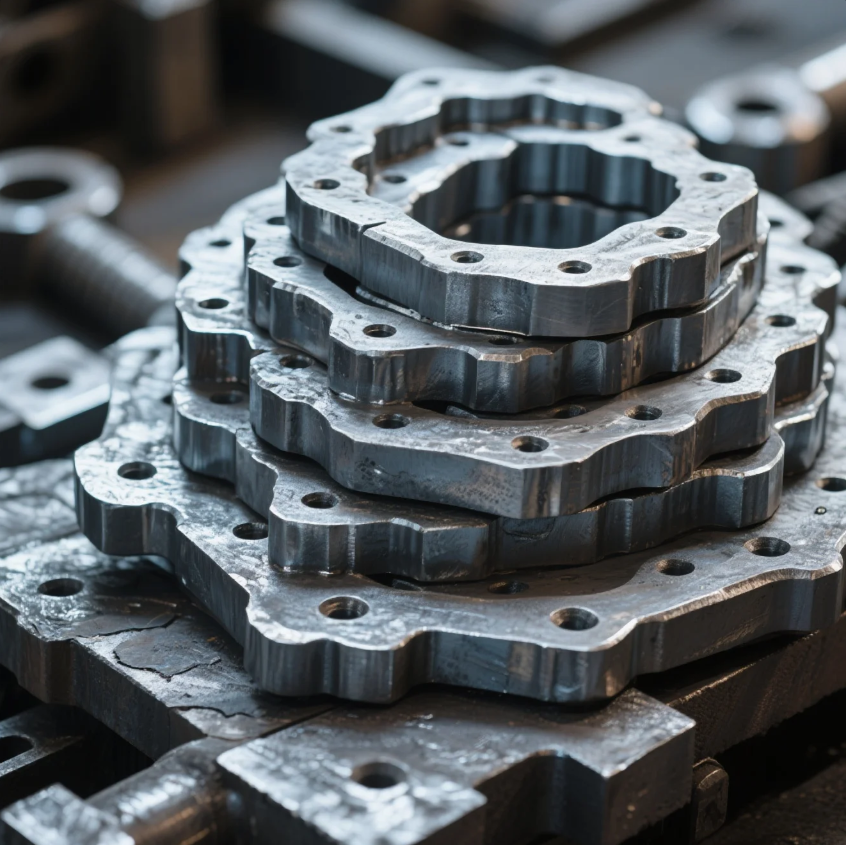

What Steel Is Not Hardenable?

Low-carbon steels, such as 1010 or 1018, are considered not fully hardenable in the traditional sense. These steels have low carbon content, which limits their ability to form martensite during heat treatment.

Non-Hardenable Steel Types:

- 1010 Steel: A very low-carbon steel that is generally used for applications requiring ductility, but it cannot achieve the same hardness levels as higher-carbon steels.

- 1018 Steel: As discussed, while it can undergo mild hardening, it does not achieve significant hardness compared to higher-carbon steels like 1045 or 1095.

Low-carbon steels like 1010 and 1018 are often used for parts that need to be shaped or machined but don’t require high hardness. They are more suited for applications where toughness, weldability, and ductility are more important than hardness.

Conclusion

Certain metals, such as lead, copper, and zinc, cannot be hardened due to their lack of the necessary crystalline structure or carbon content. Stainless steel can be hardened, but the process differs depending on the type of stainless steel. 1018 steel, a low-carbon steel, can be hardened to a mild degree but is typically used for applications requiring toughness rather than extreme hardness. Low-carbon steels, such as 1010, are not suitable for hardening and are instead chosen for their machinability and formability. Understanding the hardening capabilities of various metals is essential for selecting the right material for your needs. If you need expert advice on selecting the right steel or hardening techniques, contact Prime today for a consultation and custom solutions.