Why is stamping required and how does it apply in manufacturing and travel?

Confusion often arises because “stamping” applies to both metal forming and visa processing.

Stamping is required to authenticate, shape, or validate—whether in industrial production or international travel documentation.

Let’s explore how and why stamping plays such critical roles in both contexts.

LOOP_START

What is the importance of stamping?

Without stamping, modern manufacturing would be slower, more expensive, and less precise.

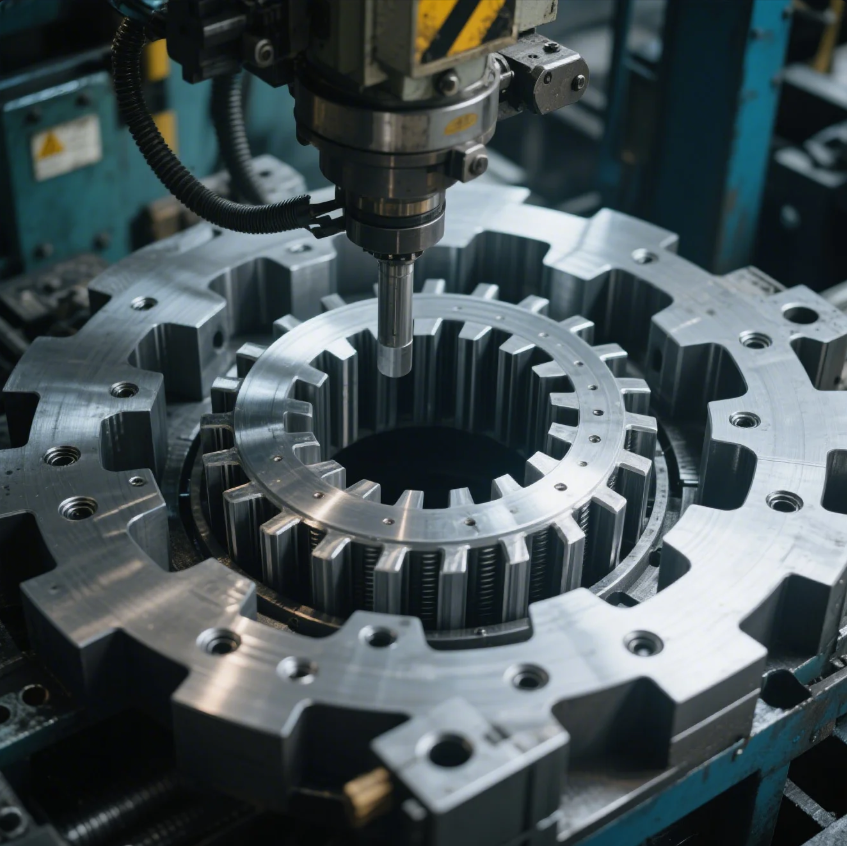

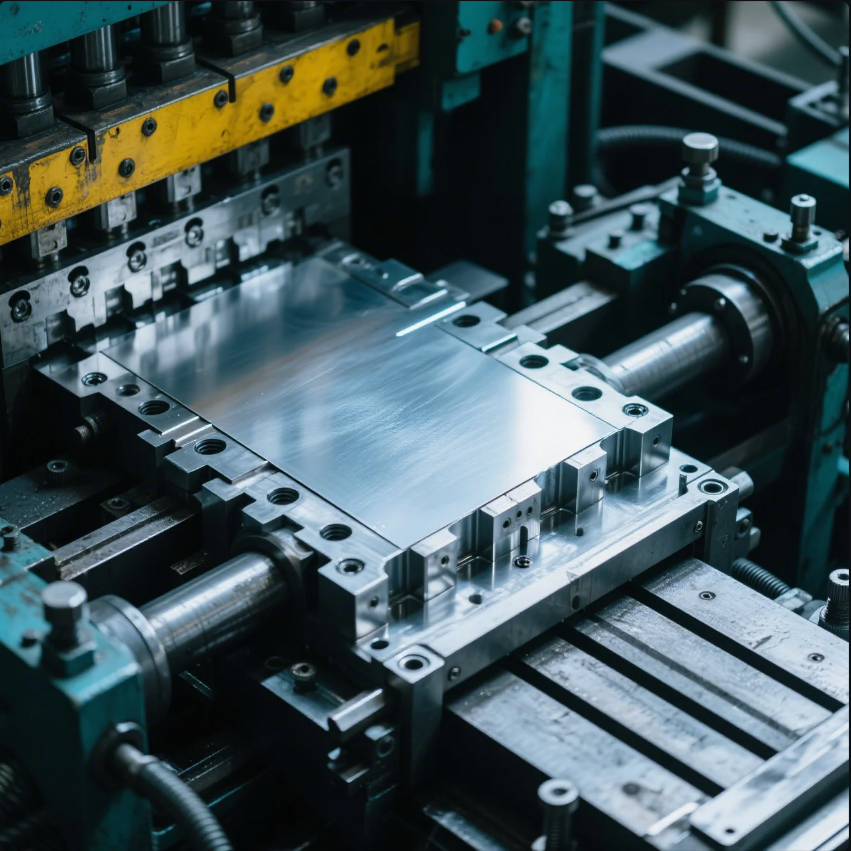

In manufacturing, stamping is important because it enables high-speed, high-accuracy production of metal parts.

Why industries depend on stamping

| Advantage | Manufacturing Outcome |

|---|---|

| Speed & Efficiency | Mass production with reduced cycle time |

| Dimensional Accuracy | Tighter tolerances with every part |

| Structural Integrity | Strong, consistent parts that meet global safety standards |

| Lower Cost per Part | Especially in mid- to high-volume runs |

Prime’s value proposition

At Prime, we use stamping to produce brackets, fasteners, CNC-integrated parts, and more. Our ISO-certified workflow ensures consistent quality, with lead times under 25 days, even for bulk orders shipped worldwide.

LOOP_END

LOOP_START

What is the purpose of visa stamping?

Travelers often confuse visa approval with visa stamping—these are two separate steps.

Visa stamping is the process of having a physical visa placed in your passport by a consular officer, allowing international entry.

What visa stamping does

| Step | Purpose |

|---|---|

| Document Verification | Confirms your identity and visa approval |

| Official Authorization | Grants permission to enter a foreign country |

| Travel Legality | Required at border checkpoints for international travel |

| Proof of Validity | Shows date, duration, and purpose of visit |

Clarification for manufacturers

Although Prime specializes in metal stamping, we understand that international clients may need visa stamping to visit factories or attend trade shows. We support clients with invitation letters and documents to facilitate smooth travel for inspections or audits.

LOOP_END

LOOP_START

Why is stamping used?

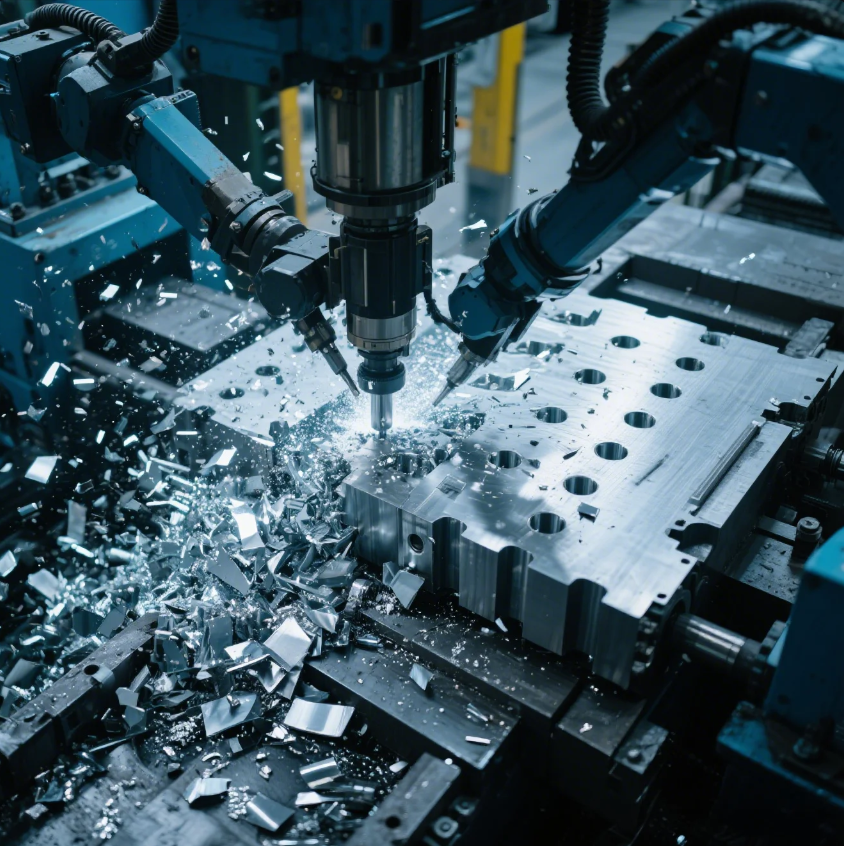

Manufacturers need to shape metal precisely, quickly, and affordably—and stamping achieves all three.

Stamping is used because it allows complex metal components to be formed with speed and accuracy, reducing labor and tooling costs.

How it compares to other methods

| Method | Stamping Advantage |

|---|---|

| Welding | Faster, no heat distortion |

| CNC Machining | Lower cost at scale, especially for flat parts |

| Casting | No need for post-processing or long cooling times |

Why clients choose Prime for stamping

We help global clients reduce production cost and improve part consistency. One client in the Middle East replaced five CNC steps with one progressive stamping operation, saving over $20,000 per year in production and labor.

LOOP_END

LOOP_START

Why is H-1B stamping required?

Professionals often overlook this step, leading to travel issues even with valid H-1B status.

H-1B stamping is required to legally enter the U.S. under an approved H-1B visa from abroad.

Role of H-1B stamping

| Reason | Outcome |

|---|---|

| Entry Requirement | Needed to cross U.S. border |

| Employer Verification | Confirms job role and visa sponsorship |

| Legal Compliance | Aligns with U.S. Department of State regulations |

| Duration & Conditions | Stamping shows validity period and work eligibility |

Support for our partners

At Prime, we have international buyers and engineers who travel globally for sourcing. We understand H-1B stamping is part of that process and are always ready to support with the documents needed for U.S. business visits, especially for on-site part evaluation or supplier audits.

LOOP_END

结论

Stamping is essential—from building precise metal parts to validating global travel—both require speed, accuracy, and formal authentication.

Need help with metal stamping solutions for your next project? Contact Prime now for a free consultation, quick quote, and global shipping—trusted for reliability, speed, and ISO-certified precision.