Why is Stamping Used? The Manufacturing Advantages of Metal Stamping

Stamping dominates metal forming because it achieves 95% material utilization at rates exceeding 1,500 parts per minute – 70% faster than CNC machining and 90% cheaper than 3D printing for mass production.

Snippet paragraph: Metal stamping creates net-shape parts with tolerances to ±0.025mm at unit costs below $0.10, making it ideal for automotive (300+ stamped parts per car), electronics (5 billion connector pins/year), and appliances (20:1 cost advantage over casting).

The automotive industry alone uses 45 million tons of stamped steel annually.

How Does Stamping Compare to Other Processes?

Speed and cost efficiency drive stamping adoption.

Snippet paragraph: Compared to alternatives:

- 3x faster than laser cutting (stamping: 1,200 parts/min vs laser: 400/min)

- 5% of the cost of CNC machining ($0.05 vs $1.00 per small bracket)

- 20x higher output than casting (50,000 vs 2,500 daily parts)

Process Selection Guide

| Requirement | Best Process | Stamping Advantage | Limitations |

|---|---|---|---|

| High volume (>50k) | Stamping | $0.001-$0.10 per part | High initial tooling cost |

| Medium volume | Laser cutting | No tooling costs | 3x slower than stamping |

| Low volume | CNC machining | Design flexibility | 10-20x higher part cost |

| Complex 3D shapes | Casting | Intricate geometries possible | Poor dimensional accuracy |

Case Study: Apple’s iPhone uses 15 stamped components per device, achieving $0.12 average part cost.

What Materials Can Be Stamped?

Versatility extends across metal families.

Snippet paragraph: Compatible materials range from 0.05mm foil to 12mm plates, including:

- Steels (mild, HSLA, stainless)

- Non-ferrous (aluminum, copper, brass)

- Exotics (titanium, Inconel® with heated tooling)

Material Stamping Properties

| Material | Thickness Range | Tonnage vs Steel | Surface Finish |

|---|---|---|---|

| Mild Steel | 0.2-6mm | 100% | Ra 0.8-1.6μm |

| Aluminum 5052 | 0.1-4mm | 65% | Ra 0.4-1.2μm |

| Brass C260 | 0.05-3mm | 80% | Ra 0.3-1.0μm |

| Stainless 304 | 0.3-5mm | 150% | Ra 0.6-2.0μm |

Special Case: Magnetic laminations stamp at 0.05mm thickness with ±0.002mm precision.

What Industries Rely on Stamping?

Nearly every sector benefits from stamped components.

Snippet paragraph: Top users include:

- Automotive (body panels, brackets, engine parts)

- Electronics (connectors, shields, heat sinks)

- Appliances (washing machine drums, oven cavities)

- Medical (surgical tools, implant components)

- Energy (solar panel frames, battery contacts)

Industry-Specific Stamping Requirements

| Sector | Tolerance | Annual Volume | Key Materials |

|---|---|---|---|

| Automotive | ±0.1mm | 50M-100M parts | HSLA steel, aluminum |

| Electronics | ±0.01mm | 1B-10B parts | Copper alloys, phosphor bronze |

| Medical | ±0.005mm | 1M-10M parts | Titanium, 316L stainless |

| Aerospace | ±0.025mm | 100k-1M parts | Titanium, Inconel |

Emerging Trend: EV battery trays now use 20+ stamped aluminum components per vehicle.

What Are the Cost Advantages?

Economies of scale make stamping unbeatable for mass production.

Snippet paragraph: A $75,000 progressive die can produce:

- 500,000 washers at $0.007 each

- 300,000 brackets at $0.03 each

- 100,000 complex assemblies at $0.12 each

Cost Breakdown Example (Automotive Bracket)

| Cost Factor | Stamping | CNC Machining | Die Casting |

|---|---|---|---|

| Tooling | $85,000 | $2,500 | $120,000 |

| Part cost (100k) | $0.38 | $3.20 | $1.15 |

| Part cost (1M) | $0.09 | $3.10 | $0.95 |

| Lead time | 12 weeks | 2 days | 16 weeks |

Break-even Point: Stamping becomes cheaper than machining at ~8,000 parts.

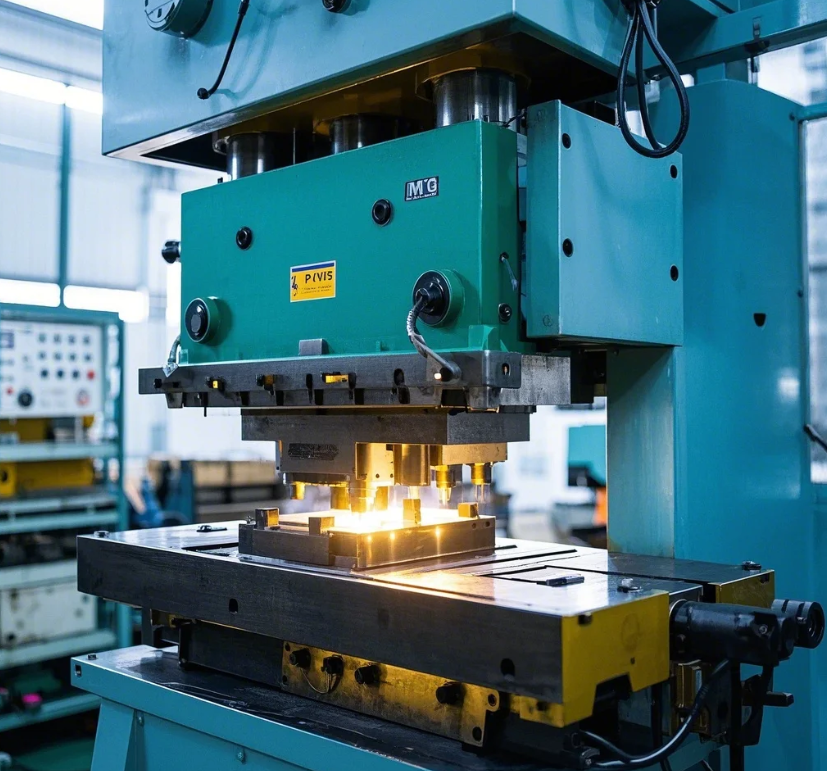

What Technical Capabilities Make Stamping Unique?

Modern presses combine precision with versatility.

Snippet paragraph: Advanced stamping achieves:

- Micro-stamping (0.01mm features for electronics)

- Hot stamping (1,500MPa ultra-high-strength steel)

- In-die welding/riveting (multi-process integration)

Advanced Stamping Technologies

| Technology | Accuracy | Speed | Applications |

|---|---|---|---|

| Progressive dies | ±0.025mm | 1,200 SPM | Electrical contacts |

| Fine blanking | ±0.005mm | 200 SPM | Gear components |

| Transfer presses | ±0.1mm | 30 SPM | Large automotive panels |

| Linear motor dies | ±0.002mm | 600 SPM | Medical implants |

Innovation Example: Sensor-embedded "smart dies" now predict tool wear within 0.003mm accuracy.

Conclusion

Metal stamping remains the undisputed champion of high-volume manufacturing because it delivers uncompromising precision at unmatched speeds and costs – from 100-ton presses forming car hoods to micro-punches creating 0.1mm medical device components, this 150-year-old technology continues evolving to meet modern production demands.